Hello readers welcome to new tutorial. here we will learn What is Hybrid Material PCB Circuit Board. The Hybrid material is a type of printed circuit board (PCB) having a composite material. The characteristics of the polygonal-type PCB are not limited to the PCB’s shape and size. Such polygonal type PCBs can be used for a wide range of electronic equipment design applications including digital electronic devices, analog electronic equipment, and semiconductor devices.

Hello readers welcome to new tutorial. here we will learn What is Hybrid Material PCB Circuit Board. The Hybrid material is a type of printed circuit board (PCB) having a composite material. The characteristics of the polygonal-type PCB are not limited to the PCB’s shape and size. Such polygonal type PCBs can be used for a wide range of electronic equipment design applications including digital electronic devices, analog electronic equipment, and semiconductor devices.Quality Assurance and Cost Effective: In early 2018, they spent $ 2,000,000 on ordering the entire set of Surface Treatment Equipment Automatic Copper Production Line. They also accept the most widely used testing and testing equipment in the industry, such as the Flying Probe Tester, X-Ray Testing Machine, Automatic Testing Machine (AOI).

With their 5 PCB and PCBA factories in Shenzhen, our prices are transparent with no additional, highly competitive costs. An online-stop self-order quote system (you just need to fill out information to get a free quote), with 24h / 7d online customer service.

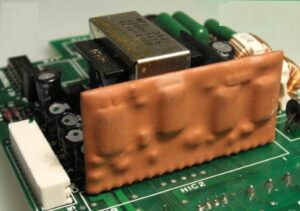

Structure of a Hybrid Circuit

- The hybrid material PCB circuit board is a class of the printed circuit. This comprises of miniature components size of electronic devices. This component gets connected to the cushioning board through soldering.

- A hybrid type of printed circuit board (PCB) polygonal comprises of a PCB that uses disparate kits. This is a widely used type of computer circuit board, this kind comes in different sizes and shapes.

- The main purpose of this kind are to have larger surface area compared to the normal types and has better conductivity and reliability as compared to the normal types. Therefore, they are commonly used in computers, mobile phones, TV-set, digital cameras, printers and in other electronic gadgets.

Hybrid Circuit Example

- A hybrid material circuit board is a type of printed circuit board (PCB) that utilizes two different components simultaneously. The two components are printed onto the same PCB, making the circuit board more complex and expensive than a traditional single-component PCB.

- The two components used to construct this hybrid circuit board can be either one or two types: a power supply and an amplifier. The power supply is used to provide energy to the amplifier, which in turn amplifies sound waves into audio signals and makes them audible through loudspeakers.

- This hybrid circuit is composed of three main parts:

- A power supply provides electrical current to an amplifier, which amplifies sound waves into audio signals and makes them audible through loudspeakers.

- An amplifier is an electronic component used to amplify radiofrequency (RF) signals. It converts RF signals into acoustic waves (sound waves), which then travel through speakers or headphones for listening.

- A speaker or headphone is a device that converts electric currents into acoustic pressure. A speaker is also an electronic component used to convert electric currents into acoustic pressure by emitting sound from its diaphragm, moving air around its edges, and reflecting sound back into space at high speeds in order to produce sound that can be heard by other people.

- The first use of the term “hybrid” was in reference to electrical devices such as telephone lines and radar systems; however, it has since come to refer primarily to electronic devices, especially computers or telecommunications equipment designed with both discrete components (“on-off switches”, “registers”, etc.) and integrated circuits (“logic gates”, “integrated circuits”) as opposed to just one component in traditional electronic devices like radios or televisions.

- This usage also continues today when referring specifically to these integrated circuits—one design using discrete logic gates and another using integrated circuits—as opposed to any other kind of circuit such as diodes or transistors that are either discretely built on top of each other on a single chip or multiple chips placed on a single substrate like silicon wafers when compared with microprocessors that incorporate both discrete logic gates integrated on a single chip as well as integrated circuits where logic gates are simply implemented as interconnected logic gates on top of transistors with associated resistors on top of them for resistance coefficients—a method called field-programmable gate array (FPGA).

- However, this description excludes some advanced integrated circuit designs whose design methodology uses multiple chips with millions or even billions of transistors stacked on

Advantages of the Hybrid Circuit

- PCB. A polygon is a conic object with a surface that has more than one face. Thus, when a polygon is used as a solid model on which to draw the circuit, it is called a solid model or polyhedron. The term polyhedron comes from Latin word “polyhedron” which means “many faces”.

- In electronics, the basic circuit elements of semiconductor devices are called components. These components can be grouped into two main classes: passive components (resistors and capacitors) and active components (transistors).

- The bulk of electronic products today are manufactured using printed circuit boards (PCB), also known as printed circuit boards (PCBs). Printed circuit boards have been widely used for decades to make electronic products, from simple photocells to complex integrated circuits like computers and smart phones.

- PCBs consist of multiple layers of material that are glued together to form the actual device itself; these layers may be different types of materials depending on application needs, such as insulative materials for use in heat sinks or non-conductive materials for use in resistive devices. PCBs may also be designed using mold making machines to produce complex shapes that cannot otherwise be made using traditional manufacturing methods.

- A modern PCB on the other hand is made up of both passive components and active components that form functional circuits that drive electronic equipment such as microprocessors and game consoles. Types of transistor types include bipolar transistors, field effect transistors (FETs), MOSFETs, metal oxide semiconductor field effect transistors (MOSFET), MEMS FETs, metal-oxide-semiconductor field effect transistor (MOSFET).

- These transistors function in a very sensitive manner based on how they operate with respect to electricity; they perform their functions by either directly controlling other electrical currents or indirectly controlling electrical currents through inductance and capacitance resonant circuits.. These circuits are formed by the combination of all these types of transistors across numerous layers which provide all audio/video signals traveling through any given area on any particular PCB.. To conclude regarding this matter

Disadvantages of the Hybrid Circuit

- The hybrid circuit is belongs to PCBs. This consists of miniature element size of electronic. This element gets linked to the cushioning board through soldering. This is suitable for the device that has some clear disadvantages such as, little space and large size, fine resolution and low cost.

- The main difference between the hybrid material pcb circuit board and other PCB polygonal is that it has finer resolution than other polygonal boards because it uses more advanced process such as laser etching, annealing, plasma etching and so on. Therefore, it will have better accuracy in precision and small size compared with other large-size boards.

- In order to ensure the quality of this product, we collect customer feedbacks in our website which can be searched by several keywords or by alphabetical order to provide you with the most accurate data about the product performance.