Hello friends I hope you all are doing great. In this post, we will discuss What is BGA and BGA assembly? As there is new techniques and technology coming in the different field of engineering and engineering-related devices. So there is usage and requirement of size integrated circuits is increasing that making our product more reliable and cost-effective.

Hello friends I hope you all are doing great. In this post, we will discuss What is BGA and BGA assembly? As there is new techniques and technology coming in the different field of engineering and engineering-related devices. So there is usage and requirement of size integrated circuits is increasing that making our product more reliable and cost-effective.

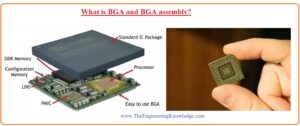

To make this small size and highly dense packaging there is the usage of large dense and less cost-creation techniques is a need and BGA is one of these techniques. In this post, we cover different facts about these techniques and also suggest to you how you can avail of these features. So let’s get started Ball Grid Array

Introduction to BGA

- The full form of BGA is Ball Grid Array. That is a small size less weight and provides good operation construction technique of integrated circuits.

- It has a resemblance to other assembly techniques such as surface mount that are used in the creation of integrated circuits. This module provides features to place numerous pinouts at the surface on a regular basis.

- The main features of technology there are a large number of pinouts exist as compared to dual inline packaging.

What is BGA Assembly

- It is a process in which integrated circuits are assembled at the BGA board. Similar to the process of SMD assembling known as SMD assembly.

- There is a need for accurate regulation and automation procedures in the BGA assembly.

- It is a very difficult and hectic process to get custom BGA and BGA assembly. There are microcircuits that exist in the Ball grid array that is not easy to work on it.

- To get custom BGA you must visit PCBWAY. it is the best electronic service provider that has a different and high level of BGA technique provider services that can meet all your requirements.

Solder paste in BGA Assembly

- In some conditions, BGA can be obtained and generally sometimes has reliability in the absence of solder paste. But in some conditions, it provides some problems in the absence of solder paste which is a fruitful process.

Benefits of Solder Paste in BGA

- BGA is a type of circuit board through which current is flowing due to the small size of circle-like balls among different parts. Its main advantages are explained here.

Large Dense circuits:

- Through the holes, circuitry provides a high-density area, and making connections of this hole is impossible to process.

Heat Flow

- The design of BGA is such that there is the elimination of heat from the board that helps to the reduction of overheating of the board.

Less value of Inductance

- The size of every solder ball in the BGA has a size of some millimeters so the issue caused due to interference in the circuit can be minimized.

Less Damaging of Leads:

- The leads of BGA are comprised of solid solder balls that have high strength and do not damage during construction.

Types of BGA Components

- There are three main types of BGA that are discussed here in detail.

TBGA:

- The TGBA has a structure with a cavity. Generally, 2 categories exist between substrate and chip. The first one is inverted solder bonding and the second one is lead bonding.

PBGA:

- In this category of BGA BT resins, lamination is used as there is a substrate and plastic packaging in the board. Solder balls are distributed in the lead and lead-free solder.

CBGA:

- The usage of this category is very older than other categories. The material used for the substrate has multilayer ceramic. The metallic coating is placed at the substrate through the usage of packaging solder to provide protection to the board, leads, and pads.

What are BGA Components?

- BGA components are integrated circuits that connect electrically to the boards via a grid of solder balls. BGA components contain different types of small metallic balls on their bottom in place of the standard packaging’s leads, which make contact with matching pads on the boards.

- This ball grid array structure is favored in many applications because it has various advantages over alternative packaging choices.

BGA Components vs. Other Packaging Technologies

| BGA Components | DIP (Dual In-Line Package) | QFP (Quad Flat Package) | CSP (Chip Scale Package) |

|---|---|---|---|

| Design and Size | Compact and small | Larger and bulky | Compact and small |

| Pin Count | High | Moderate | High |

| Footprint | Reduced | Larger | Reduced |

| Thermal Performance | Excellent | Average | Good |

| Electrical Performance | Improved | Average | Improved |

| Signal Transmission | Fast | Moderate | Fast |

| Reworkability | Challenging | Relatively easy | Challenging |

| Cost | Moderate to high | Moderate to low | Moderate to high |

What are Ball Grid Array Sockets

- Mechanical connectors called BGA sockets are created to offer a short-term or long-term electrical connection between a BGA component and PCB.

- These sockets, as opposed to soldered connections, enable simple component insertion and removal, making them the finest option for testing, prototyping, and circumstances where component replacement or repair may be necessary. To keep the BGA component firmly at its position, BGA sockets are made up of a socket body, contact pins or balls, and a retention mechanism.

Types of BGA Sockets

Compression Sockets

- A mechanism used by compression sockets exerts a certain amount of pressure on the BGA component to make a solid electrical connection. To connect the BGA component with boards in a safe and low-resistance manner, they commonly use a variety of spring contacts or pogo pins.

Zero-Insertion-Force (ZIF) Sockets

- ZIF sockets are intended to put as little strain as possible during insertion and removal on the BGA component. They consist a mechanism that makes it simple to open and close the socket, lessening the pressure put on the components of BGA

- Particularly helpful in situations involving fragile components is this kind of socket.

Solder Ball and Elastomer Sockets

- Elastomer and solder ball sockets combine dependability and flexibility. They make electrical connections between the component of BGA and the board using a variety of conductive solder balls or elastomeric contacts. High bandwidth, minimal insertion force, and great electrical performance are all features of these sockets.

Ball Grid Array Package

- The BGA package is a type of surface-mount technology package that offers an efficient and dependable way to house integrated circuits. Contrary to its forerunners, the quad flat package (QFP)and dual in-line package this package substitutes a sprinkling of tiny metallic balls on the IC’s underside for the leads. These balls make contact with appropriate pads on the printed circuit board acting as the electrical connections.

Advantages of BGA Package

Increased I/O Density

- A greater number of (I/O) connections are possible with the ball grid array package than with conventional packaging techniques. It can support a higher density of I/Os due to the usage of a variety of tiny solder balls, making it possible to handle intricate and high-performance Integrated circuits. These more connected applications, such as microprocessors and application-specific integrated circuits, benefit most from the increasing I/O density.

Enhanced Electrical Performance

- This packaging provides better electrical performance since its connector routes are shorter. Electrical traces between the IC and the boards are shorter as a consequence, which lowers parasitic capacitance and inductance and speeds up signal transmission with less signal degradation. This benefit is used in high-speed projects like high-performance computing, and telecommunications. and data centers

Better Thermal Management

- Electronic devices, especially those with large power densities, must effectively dissipate heat to function reliably. In comparison to conventional packages, this package improves in thermal management by offering a higher surface area for heat transmission. Heat can be transported from the IC to the boards more effectively thanks to the solder balls’ conductive properties. This package is a good choice for heat-sensitive applications like power devices, graphics processors, and others due to its property..

Mechanical Robustness

- The BGA package’s solder balls offer a dependable mechanical connection between the IC and the board. Because the solder balls are dispersed, there is better stress distribution, which reduces the possibility of mechanical failures such as fatigue and solder joint fractures. Applications subject to mechanical pressures benefit from this resilience, such as portable electronics, aeronautical systems, and automobile electronics.

Size and Weight Reduction

- Since electronic gadgets are getting smaller and more compact, the BGA packaging’s lower footprint has several advantages. Higher integration densities on the board are possible due to the absence of leads and the condensed solder ball layout. Smaller, lighter, and more portable electronic devices from mobile phones and wearables to Internet of Things gadgets and medical implants can be created because of this shrinking.

Why Choose PCBWAY as BGA Supplier

- PCBWAY is the most famous worldwide PCB service provider manufacturer. To get BGA services it is one of the best options for you.

- This BGA provider is equipped with 4 automated placement networks with the visualization technique that helps to do the inspection of solder ball coverage.

- There is an automated system that exists in this company having a three-dimensional laser that helps to measure the height of solder balls with that the automatic placement of CBGA.MBGA and PBGA.

- To do the verification process of BGA they used Phoenix’s real-time X-ray system.

- The size of BGA provided by the PCBWAY is almost 0.3 millimeters. The minimum distance between the circuitry line is 0.2 millimeters and the minimum distance among the 2 BGA is 0.2 millimeters. You can get also the size according to your requirements.

That is all about What is Ball Grid Array and BGA assembly are? i tried to cover each and every parameter related to this post if you have any further queries ask in the comments. Thanks for reading. Have a nice day