Hello readers welcome to new tutorial. Here we will learn SMT is better Than Through Hole. PCB is considered as the best and finest component of any project and electronic device. There are different ways used for creation of PCB board but most commonly are through hole and SMT. Both of these techniques comes with different features and advantages over other. in 1080s SMT became very common and mostly used method for PCB creation and now also employed in industries for PCB creation.

Hello readers welcome to new tutorial. Here we will learn SMT is better Than Through Hole. PCB is considered as the best and finest component of any project and electronic device. There are different ways used for creation of PCB board but most commonly are through hole and SMT. Both of these techniques comes with different features and advantages over other. in 1080s SMT became very common and mostly used method for PCB creation and now also employed in industries for PCB creation.

With the advancement in the SMT modules, the through hole has been replaced with SMD devices. In today tutorial we will learn how we can get the services from JLCPCB with reasonable prices and best features and also know how SMT better than the through-hole. So let get started.

What is Through Hole

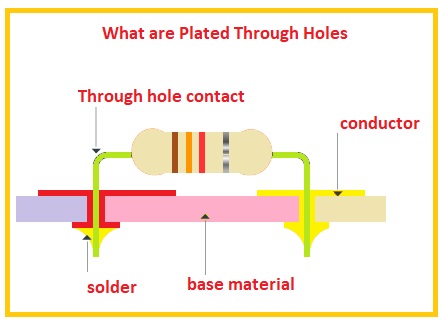

- Through hole is technique in which components pins are connect in the holes created on the board.

- Before invention of SMT in 1080s through-hole was very commonly used in industries.

- The components that needed strong links on layers needed through hole technique.

- Through holes components are linked on the board passing in the holes and has ability to bear more pressure caused by the environment that are not bear by SMT devices.

- So it preferred in military uses and aerospace where high temperatures and pressure is work.

- It also used in prototyping applications so needed manual adjustments.

Through Hole Components

- There 2 types of components used in through hole first one is axial and second one is lead.

- Axial components passed in the board in line and components are link on both sides.

- Both end point of modules place in the two holes on the board to permit components to make connections strongly.

- In case of radial lead, components components are positioned on the one side of board.

- Axial lead elements are used for snugness of PCB board and redial leads helps to cover the less area of the board.

What is SMT

- In this techniques components are link on the board surface without any hole.

- At start it called planar mounting and started in 1960s grow up in 1908s.

- Currently, it is very commonly used in different projects. Due to reduction of cost high quality and easy to handle has become compulsory for board creation.

- Basic difference between SMT and through-hole is SMT does not need holes for component connection, size of SMT component is less than through hole and smt components can be connected on both sides of board.

- The facility to place a high quantity of small elements at the board permitted to help high density and small size PCB board.

- Through-hole components pins that passes on the board and link to board layers replaced through vias.

- Surface mount elements such as BGAs are larger operating elements having small size leads.

THT Drawbacks

- The creation of numerous holes on the board is main disadvantage of through-hole.

- That increases the creation procedure and increases the prices of board creation.

- As the hole is compulsory to retain elements at the position so they restrict the production area and routing area for tracing.

SMT Advantages

- This technique used to make firmly strong components and board.

- It provides the long life board.

- These boards has ability to bear larger temperature.

- It also offered the feature to connect the larger size and weight components.

How to get SMT Service

- There are various PCB manufacturers operating in the world that provide PCB-based services at different prices and levels.

- There is a highly reliable and reliable PCB supplier by JLCPCB. JLCPCB is the leading provider of THT and SMT services in one place at affordable prices and features.

- For THT and SMT services send information to JLCPCB sites their team will contact you to get all the boarding details according to your requirement.

- Their engineers are waiting for you to help design and create your projects according to needs.

- JLCPCB comes with a variety of features such as low prices with fast delivery of high quality. So they also offer discounts from time to time to their regular customers with special discounts so you have to attach them to get the best services they will never disappoint.

- Whether you are creating your first PCB, or developing a hardware product, they are here to help you build hardware easily and quickly by providing you with a quick PCB example and SMT integration service.

- They are constantly looking for new ways to improve and shorten the PCB prototyping process – from the introduction of an online quote/order system, and automated production to faster delivery.

Comparison between SMT and through hole

- There is no existence of pads and vias in through hole while SMT has

- Soldering process can be done by manual and automation in smt it is done in automation.

- Through-hole has through-hole testing point and while SMT has through-hole and SMT

- THT needed large size schemes and SMT need small size

- Its comes with features of single-sided components and SMT has two sided components connection.

SMT is better Than Through Hole

- SMT is high speed and has reliability and it needed a complete review of the process. It needed a certain specialty for designing.

- Larger elements can be positioned on the less position. So it is less expensive process and fault free.

- Components can be assembled on both side of board.

That is all about the SMT is better Than Through Hole . I have explained all details about the features and also have explained to you how you can get the SMT services from best PCB supplier JLCPCB.