Hello friends, I hope all of you are doing great. In today’s tutorial, we are gonna have a look at the introduction to Plc (Programmable logic controllers). Programmable logic controllers (PLCs) is a new invention for our industries. After its creation, our working in industries and controlling different devices has become very easier. It replaced the wired relay system which was very complicated and difficult to handle. There are many controlling systems exists but Plc importance can’t be denied. For different automation procedure plc is the best choice of controllers. Nowadays it integrates minor circuitries, faster CPUs, network systems, and numerous Internet equipment.

Hello friends, I hope all of you are doing great. In today’s tutorial, we are gonna have a look at the introduction to Plc (Programmable logic controllers). Programmable logic controllers (PLCs) is a new invention for our industries. After its creation, our working in industries and controlling different devices has become very easier. It replaced the wired relay system which was very complicated and difficult to handle. There are many controlling systems exists but Plc importance can’t be denied. For different automation procedure plc is the best choice of controllers. Nowadays it integrates minor circuitries, faster CPUs, network systems, and numerous Internet equipment.

Plc has become the most popular instrument for industries to control different processes that is performing in the industry. It is an industry type computer that is programmable for controlling functions. Due to its programmable capability wiring control system been removed from industries like relays controlling. The main advantage is its programming language is very simple there is no need to use specific tools like other computer languages such as C, C++, etc. In coming tutorial, we also learn about its programming language and its working. So let’s get started with an introduction to PLC.

Introduction to Plc (Programmable Logic Controllers)

- Programmable logic controllers (PLCs) is a new development for our industries. After its creation, our working in industries and controlling different devices has become very easier.

- It was intended for numerous input and output arrangements, higher temperature ranges, resistance to electrical sound, and opposition to pulsation and its effect.

- Programs for the controller and process of industrial apparatus and equipment are typically stored in battery-supported or non-volatile storage.

- A PLC is like an actual system because the output of any process that is under control of PLC depends on the inputs.

- From this, we can say that plc is generally a digital computer which builds for controlling the machine.

- Different from our personal computer it prepared for according to industry working situations and it consists of special input and outputs and its special programming language.

- At its creation time, it was considered the replacement of relay but due to many functional capabilities, it started working in numerous complicated industrial submissions.

- As its construction is the same as the computer, it has ability to work not only for relays switching but also perform many applications like time calculation, counting, comparison, and processing of different analog signals.

- Plc has numerous benefits over a conservative relay using controlling. Relay uses many wiring but plc avoids wiring system and relay can be used only for single or specific function but plc performs many functions.

- In case of a relay in automobile industries, we have to change all wiring of a control process which makes its use expensive but plc has removed these wiring systems.

- It is small and cheap related to corresponding relay-centered procedure controller schemes.

Benefits of PLC

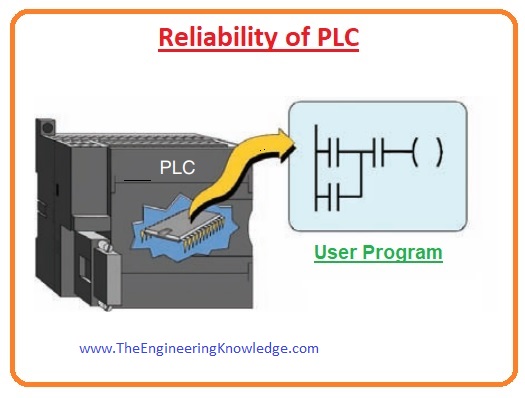

Reliability of PLC:

- When one program is typed and implement by plc it can easily use for other plc devices. Because these program has been easily saved in plc memory.

- As all the logic programs are stored in the memory storage of the plc, so there is a minor chance to damage this program.

- The program has been taken the place of abundant exterior cabling that would usually be obligatory for a controller of different processes in industries.

- PLCs also offers the reliability-related with solid-state elements like electronic components.

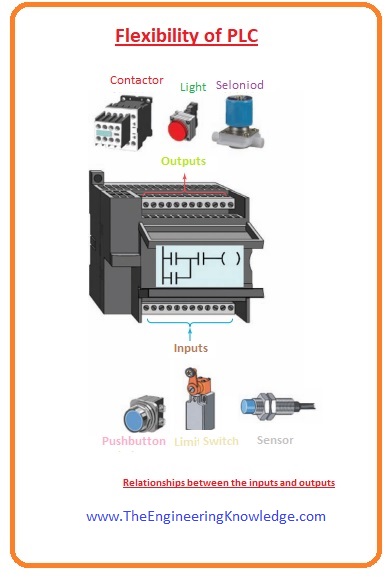

Flexibility of PLC

- It is very easy to make any program and change it in plc, while in relay system it’s very difficult to connect wire and disconnect it.

- The working of inputs and outputs are defined by the program, not there connection define there working.

- If there is a need to update system just change our program which is updated not all connection of our system.

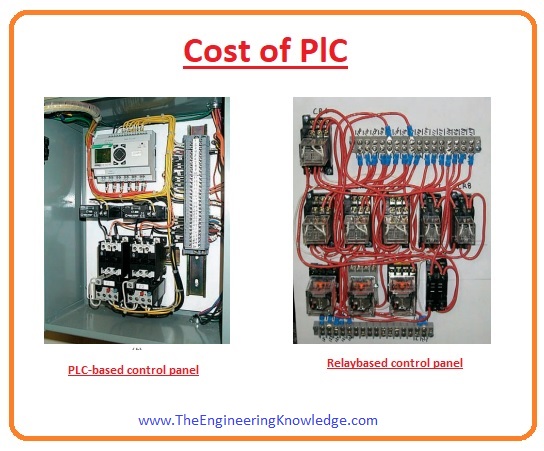

Lower Cost plc

- PLCs were initially manufactured to substitute relays, and the less price has been so important that relay controller is becoming outdated excepting for power submissions.

- Normally, if any system has more than around a half-dozen relays in circuits, it will maybe be less costly to use a PLC.

- From the figure, we can see that there is a lot of wire in relay circuits but in plc, few are used which make it cost-effective.

Communications Capability of PLC

- The plc has the ability to communicate with other plc controllers or computer devices to work as a supervisory component, to get data, to monitor other controllers and for sending and receiving of different programs.

- In given diagram plc communication module is shown.

Faster Response Time of plc

- PLCs have ability to work such circuitries that required a high-speed operation.

- The programmable controller works in actual time, which means that any operation will show its output at a given time.

- Types of machinery which work on thousands of substances per second and matters that apply only a portion of a second in obverse of an instrument need the PLC’s rapid reply competence.

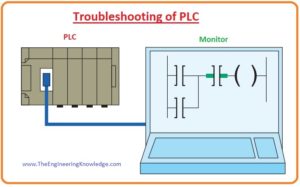

Easier to Troubleshoot PLC

- Plc consists of such function which permits the user to detect and resolve problem occurs in the program or any circuit.

- After solving problems and finding it we can easily show it on a monitor. The given diagram shows this process.

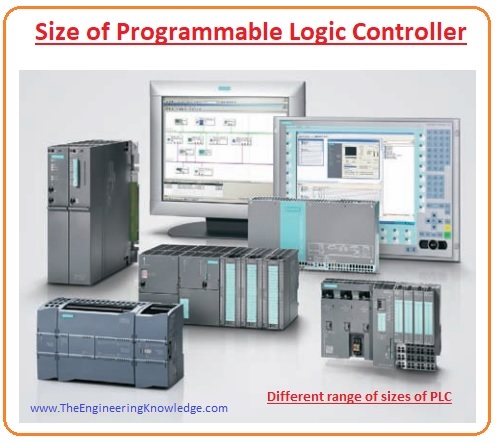

PLC Size

- The standards used for categorizing the plc are followed it functions, how many inputs and output it has, its price and main thing is its structure size.

- One of the most factors which are countable is its input and outputs.

- Its smallest module which is known as Nano consists of 15 inputs and outputs points.

- Larger then this Nano is a micro-size that has 15 to 128 input and output pinouts.

- Greater then micro size there is a medium-size plc is available which known as 128 to 512 input and output pinouts.

- The larger size in which it exists consists of above 512 input and output pinouts.

- Different sizes range of plc is shown in given diagram.

Applications of PLC

- There are a lot of applications of PLC but important three applications which are described below.

- Single-ended

- Multitask

- Control management.

Let’s discuss one by one with a detailed description

Single-Ended PLC Application

- A single-ended PLC submission contains one PLC controller to control and monitor a single process.

- It will be a single unit and cannot be used for communication with other processors or PLCs.

- The dimension and complexity of the procedure which to is measured are noticeable aspects in determining which PLC to choose.

- The applications can ask for bulky CPU, but generally, this class needs a smaller PLC.

- The diagram shows the single-ended applications of plc.

Multitask PLC Application

- In multitasking applications of PLC one plc controller monitors many procedures at the same time.

- Acceptable input, output capability is an important aspect in this category of applications.

- If the PLC is a sub-system of a bigger procedure or process and will have to connect with a central PLC or processer, then there will be a need of large system of communication.

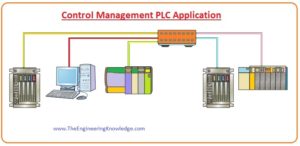

Control Management PLC Applications

- We discussed in multitasking applications that one plc control many processes. But in case of control management Plc, one plc controls many other plc devices.

- This type of submission needs a larger PLC CPU manufactured to connect with other PLC controllers and possibly with a processor.

- The control management PLC administers numerous PLC processors by taking (download) programs that give instruction to other plc processors what they will have to do.

- It should have ability to make connections with other processors so that by appropriate instructions it can connect with anyone it desires to.

Memory of PLC

- Memory is the portion of a Programmable Logic Controller that gathers statistics, commands, and the controlling programs.

- The space or size of storage of plc normally denoted as (K), like (1k), (2k), etc.

- The (K) is an abbreviation of kilo usually it denoted 1000 units.

- But in case of computers and Programmable Logic Controller, one (k) is equal to 1024, since these calculations are founded on the binary numeral system.

- According to the memory category, one (K) can be denoted as (1024 bits), (1024 bytes), or (1024 words).

- While it is general for us to calculate the storage capability of PLC in words, we required to see the number of bits in every word before the storage dimension can be precisely related.

- The volume of memory needs to be designed according to the applications.

- Before the installation of the plc, some factors that should be in the notice explains here.

- Quantity of inputs and out connections.

- The magnitude of the program controller.

- Statistics gathering necessities

- Controlling functions requisite

- Future developments

I have mentioned each and everything related to PLC if you have any questions ask in comments. See you in the next tutorial, parts of PLC.

it’s looking nice I am waiting for the next Article…

Thanks for your tips on this blog. 1 thing I wish to say is purchasing electronic products items in the Internet is not new. The truth is, in the past decade alone, the marketplace for online electronic devices has grown considerably. Today, you could find practically just about any electronic device and other gadgets on the Internet, which include cameras along with camcorders to computer components and gambling consoles.