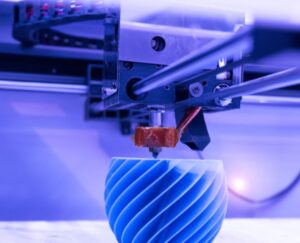

Hello, readers welcome to the new post. Today we will discuss How FDM 3D printing works. FDM or Fused Deposition Modeling is a technique that operates in two directions horizontal and vertical, in this process extrusion nozzle moves on the building structure. The process consists of the use of thermoplastic material which gets the melting point and after that forced out to make three-dimensional objects layer by layer the printer nozzle is arranged for the next layer of plastic that is to be added to the structure. When an object is created material used for supporting the object is removed.

Hello, readers welcome to the new post. Today we will discuss How FDM 3D printing works. FDM or Fused Deposition Modeling is a technique that operates in two directions horizontal and vertical, in this process extrusion nozzle moves on the building structure. The process consists of the use of thermoplastic material which gets the melting point and after that forced out to make three-dimensional objects layer by layer the printer nozzle is arranged for the next layer of plastic that is to be added to the structure. When an object is created material used for supporting the object is removed.

Different processes use FDM 3D printing technology since it makes detailed and accurate objects. So engineers use this technique to permit them to test parts for accurate configuration testing. It is a technique that is used for the creation of small parts and different tools which were difficult to manufacture.

Every type of 3D printer uses FDM 3 D printing with common 3D printed material like Polylactic Acid, called PLA. With that other materials like PEI and PEEK are also used. The technique that uses FDP was first time used in the 1980s that resulted in common-use technology. In this post, we will discuss the details of the 3D FDM printing service of PCBWAY and learn how can use the service of this PCB supplier. So let’s get started How FDM 3D printing works

How FDM 3D printing works

- FDMor Fused Deposition Modeling is a three-dimensional printing technique that mostly uses due to its speed, accuracy, and reasonable prices.

- The FDM machine accurately extrudes melted plastic filament to make parts. FDM parts can be created normally in a single day.

- Like other types of 3D printing, FDM uses digital desing which is uploaded to the printer. There are many different polymers used like PEEK, PEI, ABS, and PETG.

- It is configured to the shape of plastic threads that are fed from the coil and through the nozzle. Filaments melted and added on the base called a build platform or table having a base and nozzle both are controlled through a computing device.

- The computer operates by translating the object and its dimension into coordinates which make such a structure pass through the nozzle and base.

- When the nozzle moves about the base, the plastic cools and transformed into a solid making a hard bond to the previous layer.

- For this configuration, the printhead moves in sequence for the next layer of plastic to apply. As three-dimensional printing is an effective and fast technique but it takes some time to make an object depending on the size.

Benefits Of FDM 3D Printing

- Fused deposition molding can make fully functional parts in standard plastics. Through they have anisotropy in the Z direction or vertical and step structure on the surface.

- Fused deposition modeling operates through standard materials like ABS, PA or PC. SO parts provide good mechanical features and operate for long time intervals.

- Parts can be post-processed as any plastic part generated through a conventional production process.

PCBWAY FDM 3D Printing Advantages

Accuracy

- PCBWAY use state-of-the-art industrial FDM 3D printers designed to meet tolerances of +/- 0.004” or +/- 0.002” per inch, whichever is greater.

Large Build

- FDM can produce high volume FDM parts up to 24″ x 36″ x 36″

Real Thermoplastics

- FDM has the largest range of true engineering thermoplastics.

High Strength

- FDM printed parts are available in a variety of high-performance plastics for applications that require resistance to the elements

Rapid Turnaround

- FDM parts require no tools, reducing production time from weeks to days

Part Production

- FDM is able to produce end-to-end parts on demand, increasing throughput and helping you get to market faster.

FDM 3D Printing Disadvantages

Surface Quality

- Extruding the material layer by layer, the surface has layered lines and fine details cannot be realized

Layer Adhesion

- The parts have anisotropy in the z-direction (vertical direction) and the properties are weaker than the base materials.

Scale Effect

- Unit cost and lead time will not be reduced as much as cast or molded parts.

PCBWAY FDM 3D printing service Details

| Requirement | Specification |

|---|---|

| Maximum build size | 1300 x 1300 x 1300 mm |

| Minimum wall thickness | 1.5mm |

| Dimensional accuracy | L<100mm,±0.2mm. L>100mm,±0.2%*L(mm) |

| Layer height | 100-300 μm |

| Infill | 20-100% |

Fused Deposition Modeling 3D Printing Materials

- Fortus FDM Materials Available at PCBWay

PLA

- PLA (FDM) is used for low-cost, non-functional prototyping. It offers more detail than ABS but is more fragile. Not suitable for high-temperature applications.

ABS

- ABS is a common thermoplastic with good mechanical properties and excellent impact strength, better than PLA but with less defined details.

PEEK

- PEEK is an engineering thermoplastic with excellent mechanical and thermal properties. Can be used to replace metal parts.

ASA

- ASA is a production-grade thermoplastic that can be combined with FDM technology for ultimate performance. ASA can build durable prototypes to test assembly, shape, and functionality, or produce practical end-use parts for outdoor use. From housings and electrical equipment holders to sporting goods and car prototypes, ASA materials can make your designs more profitable.

PETG

- PTEG is a very tough, durable, and easy-to-use material. The strength of PETG makes it the material of choice for food packaging. Its natural chemical underactivity makes it invaluable in medical applications and is used for orthopedic and prosthetic devices.

PC (Polycarbonate)

- PC offers precision, durability, and stability, creating solid parts that can withstand functional testing.

PCBWAY standard surface finishes

- Here is a list of standard finishes. For custom finishes such as electroplating or polishing, please contact [email protected].

Spray painting

- Get painted according to the color pattern supplied by the customer (Including matte paint, high-gloss paint, electroplating, paint, leather paint, etc.).

Polished

- The surface structure is polished in different ways to meet the actual needs of customers. Transparent parts can be polished accordingly to improve transparency and light transmission.

Electroplating

- Provide electroplating services, improve the overall strength of components, provide a metal-like surface structure, and ensure that they have certain properties of metal.

Inlay nut

- An internal thread is machined at the specific position of the bottom hole that needs to be machined.

Glazing assembly

- The surface of the piece is glazed to better imitate the look of handwork. Have mature assembly experience to ensure overall product display.

Reinforced coating

- The unique processing ability of the outer coating improves the strength of the product structure, reduces external wear, and can better prevent damage caused by normal storage and use.

Testing Service

- Various measuring devices provide reasonable measuring services according to the actual needs of customers.

That is all about the FDM 3D printing all details has explained. If you have any query ask here. Further must visit PCBWAY to get the FDM 3D printing. That is best in all services related to PCBWAY and other related products. Thanks for reading have a good day.