Hello, friends welcome to the new Tutorial. In this post, we will have a learn about What is Metal Core PCB. PcoverrCB is a printed circuit board that employed in different projects and has many types according to uses and configuration. Metalcore PCB is such type of PCB board that consists of base material created with the use of the metallic substance. The metallic core assembled on this board helps to do the redirection of heat generated through the elements that are placed at the board.

Hello, friends welcome to the new Tutorial. In this post, we will have a learn about What is Metal Core PCB. PcoverrCB is a printed circuit board that employed in different projects and has many types according to uses and configuration. Metalcore PCB is such type of PCB board that consists of base material created with the use of the metallic substance. The metallic core assembled on this board helps to do the redirection of heat generated through the elements that are placed at the board.

In this post, we cover the details about its construction working applications and related features. Also, introduce to you such a supplier that can help to make metal core PCB easy and with affordable prices. So let get started

What is Metal Core PCB

- The Metal core PCB uses based material created through the use of metallic substances. the board created through the use of FR4 and CEM3 has metal that increases thermal conductive behavior.

- The COre is created through the use of a metal plate that has certain parameters of the area to do the dissipation of heat.

- The core is created through the use of copper, Aluminum, and alloy created through the use of steel.

- The metallic Employed in this board is chosen according to configuration and practical uses.

- The use of metal increases the heat-dissipating ability eight to nine-time more than other substances used for core construction.

- As the main purpose of the metallic substance used in this board is to reduce the heat dissipation so net operation life of the component assembled will increases.

- the use of metal decreases the certain type of heat reduction instruments near the board installation.

How to Construct Metal Core PCB

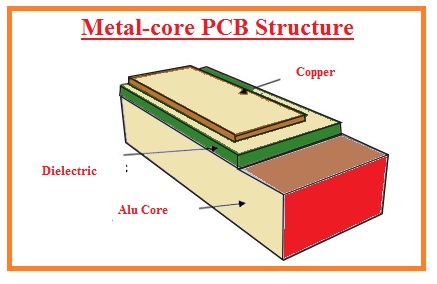

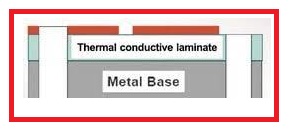

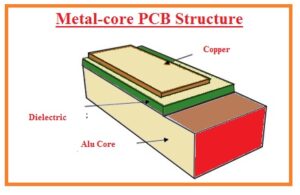

- The construction of this board is simple in a normal one-sided metal core PCB the sheet of the copper layer is wounded to the layer of dielectric substrate that is thermally conductive.

- Over this dielectric sheet, there is a layer of the metallic substance of aluminum or copper is rapped.

- The core is created through the use of certain metallic that used to heat dissipation has a certain thickness.

- The value of thickness lies in the range of twenty mils to one twenty mils. in the case of copper, the thickness range is from one oz to ten oz.

- In the construction of this board, the metallic portion has high thickness than others. Generally, thickness measurements are one millimeter, 1.5 millimeters.

- the other advantage of this metallic sheet is to offer rigidness, sustain the structure of the board that fulfill the standard requirements.

Metal Core PCB Type

- The main types of this board are explained here with the details.

Single Layer Metal Core PCB

- In the construction of this PCB board, there is one layer of dielectric sheet copper conductor and metallic sheet at the base is used.

- There are 2 main functions of dielectric used in this board first is to offer the heat transformation among the different elements placed at the board that provides the system protection from electric shocks.

COB Metal Core PCB

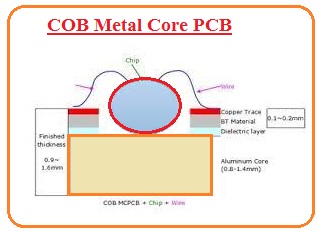

- The full form of COB is chip-on-board PCB. In this board there is different method is used as compared to others.

- In this board, there is the usage of the microchip to do the dissipation of heat correctly. There is a physical connection among the conductive layer and base created with the use of metal. So in this board, there is no usage of dielectric material

Double-Sided Metal Core

- In this board there are 2 sheets of copper material is used. these 2 sheets are placed at a single part of the metallic part.

- It needed an extra pose to make assembly between layers of the board.

Multiple Layer Metal Core PCB

- There are larger than 2 sheets of copper material is used in this board. With the increment in the number of layers, there is complication occurs in the structure of this board.

- For the design of this board, there is expert engineers are used to making this board.

- Till now we have a lot of info about metal core PCB and want to get this board to make your project I am suggesting to you a very good and effective supplier of this board that is PCBWAY offered good quality PCB to you with manufacturing services.

- To provide services related to the board there is a team of high-quality and professional engineers to fulfill the requirements of the board.

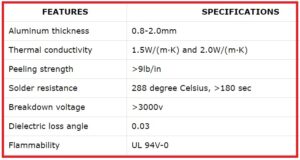

- The main features offered by the PCBWAY for this board can see here.

- With reasonable cost, they offered the PCB types like one-sided double-sided, and multiple-sided according to users’ requirements.

- They make sure that before delivering the order to users complete the all testing process required

Benefits of Metal Core PCB

- This board offered good thermal conductivity due to the usage of aluminum and copper.

- If we do a comparison between FR4 and metal board then come to know that their good protection offered by this board for protection of elements used at this board.

- It comes with features that there is a change in the physical dimension of this board according to variation in the surrounding temperature. Coefficient thermal expansion is this board. Its thermal expansion coefficient is less than FR4 so decreases the damaging of the board.

- The metallic substrate offered a long time operation as compared to other ceramic substances. These PCBs increase the net strength working of the board.

So that is all about the metal core PCB if you have any further query ask in the comments, Thanks for reading. Have a nice day