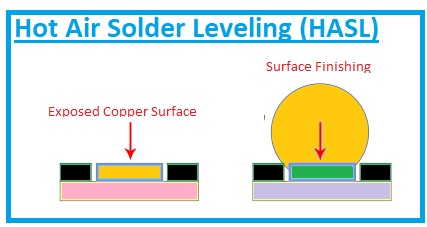

HASL or Hot Air Solder Leveling is a commonly used PCB surface finishes in PCB industries. HASL consists of solder having sixty-three percent tin and thirty-seven percent lead. But this finish is also applied on a lead-free board with some changes in the application process. it is a more cost-effective finish than other categories of finishes and is mostly preferred for general-purpose boards. HASL has dominated the PCB surface treatment process which is the finest option for larger size components and wires that has later spacing. But with that industry has reduced the use of HASL since it is an unpleasant, dirty, and difficult process.

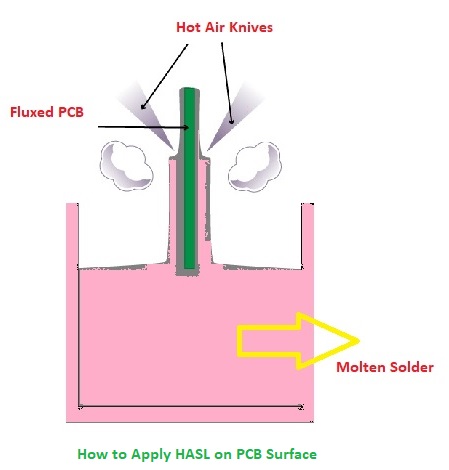

How to Apply HASL on PCB Surface

There are three steps involved in the application of HASL on the PCB board. The first one is cleaning, the second one is fluxing and the third one is spraying molted solder to get the required wetting. Then hot air knives are used for the removal of additional solder. Air knives modules that are adjusted over the melting temperature of the solder. When solder becomes solid boards are passed through the washer to eliminate the flex residue

Some HASLs are configured at an angle of ninety degrees that helps boards to completely dip in the bath of solder in results high-quality finishes are obtained. There is an option for horizontal lines to use. In this configuration, the board is immersed to solder through the nozzle or rollers connected with the upper and lower parts of the panel. Through the horizontal process, uniform thickness is obtained then vertical since there is zero impact of gravity involved during solder distribution.

As HASL has good wettability so it is preferred over other finishes. It has features to withstand the solder material for a longer time without the use of any protected material. The finish quality can be measured through air pressure, board movement towards solder and away from solder during dipping, and air knives angle.

This technique is effective for soldering components but the surface is not compatible with fine-pitch elements due to thickness. HASL deposition has a tin and leads eutectic mixture. It is the finest option for through holes and larger size smt components. it is not the finest option for smt components less than 0805

Features of HASL

- HASL has a longer processing window. It can be applied for manufacturing schedules that not need a larger amount of boards to create fastly.

- it has good aesthetic parameters

- it provides a uniform thickness of the coating. Thickness depends on the volume of solder existing on the pad after moving through the hot knife and hot tension forces.

- The soldering process involved causes the non-wetting or dewetting when solder coating does not completely intermetallic layers.

Lead-free HASL

Lead-free hot air soldering type of surface finish that uses lead-free soldering alloy. There are different alloys that do not have a lead that is used by lead-free HASL than tin-lead eutectic alloys that are used by HASL. During the application of lead-free HASL on board molted solder is first used on board to get wetting. After that knives are employed without lead.

When the solder becomes solid circuitry board is moved through the washer and removed like the HASL. Instead of considering the environmental alternative for standard HASL, lead-free HASL is less used for surface finishing. The reason is that other some other finishes are readily accessible such as ENIG and OSP

Differences between HASL and Lead-Free HASL

Here are some basic differences between HASL and Lead-Free HASL explained.

- Hot air surface leveling employed lead with solder alloy that is harmful to humans and the environment lead-free hot air surface leveling not uses lead as solder alloy so it is environmentally friendly and less hazardous.

- HASL has less melting point hen lead-free HASL since lead melting point is low than other materials.

- Lead Tin solder or HASL provides a bright and shiny surface when applied on the board. While lead-free HASL provides dull and dim surface board

- Lead tin surface finishes provides good mechanical strength than lead-free surface finishes

- The selection of accurate surface finishing for PCB manufacturing is necessary. during board manufacturing. These measures are necessary since boards are commonly used in different electronic projects and devices from industrial machines to small children’s toys.

- Leadn content in HASL lead-free is not more than 0.5 and HASL has 37

- Lead used enhances the operation of tin wire for the welding process, so the lead wire is easy to use than lead-free wire.

HASL to Lead-free HASL Transition

The strict RoHS rules insisting different manufacturers use lead-free HASL in place of tin-lead HASL. In lead-free HASL lead free alloy used and a smooth, flat surface finish is obtained. This finishes is easy to solder and less hazardous. The coating is uniform so has less coplanarity issues that are commonly produced through HASL. It is the best option over HASL since avoids some issues. That are:

- stencil gasketing for solder paste printing

- coplanarity problems

- board damaging

Advantages of HASL

HASL is the main type of surface finish of PCB that comes with some advantages listed here

- HASL can be easily inspected through the naked eye on the surface of the board.

- It provides good wetting through the process of connecting and soldering elements

- There is the oxidation of copper is not done on this finishes

- It is easily accessible so that is its main benefit over other finishes

- This finishes enhances ht operation life of the board

- It is a less expensive finish and uses less costly material

- It is easy to apply on board there is no need for certain equipment to apply this finish

- The board having HASL can operate at temperatures up to 265 centigrade.

HASL Disadvantages

With different advantages, there are some drawbacks of HASL that are listed here

- It is not the best option for SMT since it involved irregular surfaces during the hot air soldering process

- This finishes involved high temperature so plated through the hole can be damaged due to temperature

- HASL int to fine option for line binding

- It does not handle the tight tolerance on plated holes

- High heat causes damage to the board when this finishes applied

- It is not good for fine pitch and needs horizontal levelers to increase their flatness

Hot air surface leveling used in surface finishing is a very common part of the PCB industry. Here we have learned the complete differences between hot air surface leveling and lead-free hot air surface leveling and these two finishes have their respective mechanical and physical strengths for practical use. As HASL is a less expensive solution for PCB surface finishes but it is not compatible with RoHS. So we should make sure of high safety over use of these finishes for our PCB industries and practical use