Hi friends, I hope all of you are fine. As you already know we have started a series of PLC articles. In the last lecture, we discussed a detailed article on PARTS of PLC. In today’s tutorial, I am going to explain to you a detailed article on the working of PLC. After reading previous articles about plc and its part I hope all of you have become well aware of plc and its part. Now you can understand its working very easily.

Hi friends, I hope all of you are fine. As you already know we have started a series of PLC articles. In the last lecture, we discussed a detailed article on PARTS of PLC. In today’s tutorial, I am going to explain to you a detailed article on the working of PLC. After reading previous articles about plc and its part I hope all of you have become well aware of plc and its part. Now you can understand its working very easily.

In this article, we will discuss the detailed working of plc and its comparison with the relay working. Also, we will discuss its modified operation and how we can modify it manually. So let’s get started with a working principle of plc.

Working Principle of PLC (Programmable Logic Controller)

- plc meaning is programmable logic controller. To learn about plc working principle we discuss a simple example in which we study its manual process control, then relay control and finally how we can control this process by plc.

- First of all, we discuss manual control or process.

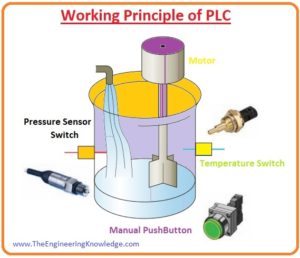

- In given diagram, we take an example of a motor control mixer. In this process we are using two sensors, the first one is temperature other one is pressure.

- These two sensors are connected with the motor and their values have already set.

- When we start a motor with manual push-button motor mix the liquid and when set value of temperature and pressure is reached the connected sensor make their contacts closed and tell about process control. By knowing this we can start or stop our motor.

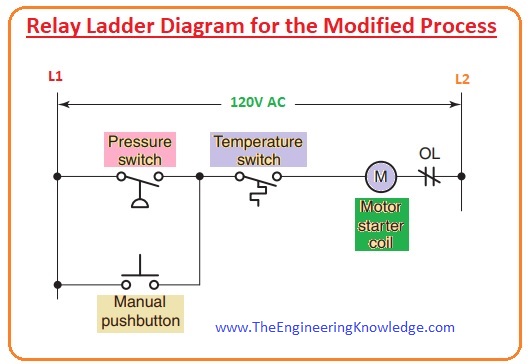

Motor Control by Using Relay

- As we have discussed a manual method of the motor controlling now we discuss how to relay control this process.

- In given relay ladder logic diagram we can see that the motor will start working when both temperature and pressure switches are connected or the motor will work when we press a push button.

- Till now we have discussed motor control by manual and relay method now we discuss this process how we can control by plc.

Working Principle of PLC

- Now we discuss how we can implement plc for this process.

- For plc, we are also using the same input components that we used in previous methods, like pressure, temperature switches, and push buttons.

- These components are connected with the plc input module connections which are designed by the manufacturer.

- In this example, we use 120v AC modular whose input connection is shown in a given diagram.

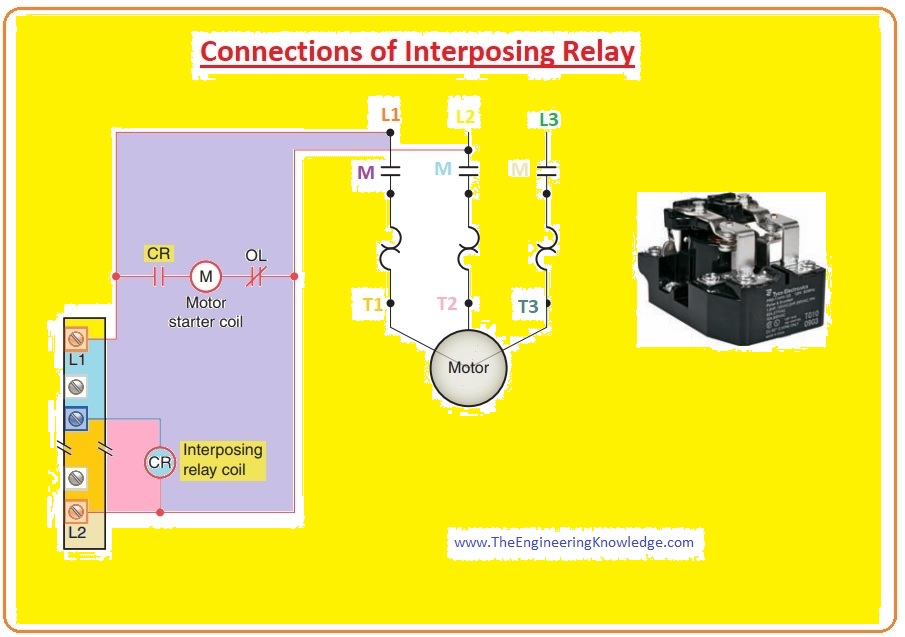

- In this process, we also use the same output component which is the motor.

- This output device is also connected with the output module of plc according to manufacturer’s output connections scheme.

- Distinctive installing links for a 120V AC modular arranged output unit are displayed in a given diagram.

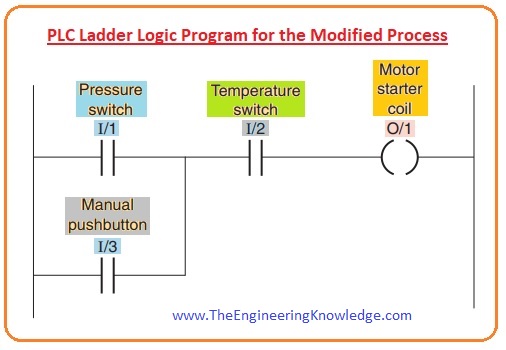

PLC Ladder Logic Program with Addressing Scheme

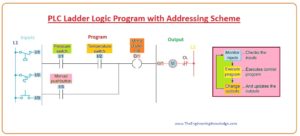

- The PLC ladder logic program is built and fed in the storage of the Central Processing Unit.

- A distinctive ladder logic program for this procedure is displayed in a given diagram.

- The arrangement used is similar to the arrangement of the wired relay ladder circuitry.

- The discrete symbols in this circuit signify commands, while the numbering signifies the order position statements.

- To give programming instructions to the controller, you feed these commands one by one in the CPU memory from the programming component.

- Every input and output component will be assigned a special location address which will allow plc to know about where it is physically connected.

- The input and output addresses will be different for different manufacturing companies.

- Commands are put in the user program part of the CPU storage.

- Throughout the program scanning, the controller observes the inputs implements the controller program and vary the output consequently.

- In the above diagram, we have discussed input and output configuration with the plc now we study how this program runs in plc.

How to Run Program in PLC

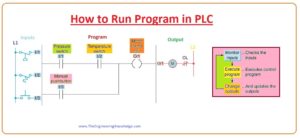

- For the program to work, the control is located in the running style or functioning sequence.

- Through every working rotation, the controller inspects the position of an input component, implements the operator program, and varies outputs consequently.

- Every sign like this can be considered as a set of typically open connections. The sign () is used to signify a loop that, when gets energized, will close a set of links.

- In given below ladder logic program we can see that the coil (O/1) will work when links (I/1) and I/2 are locked or coil will work when link I/3 is closed.

- A PLC works instantly which means when one program works it also gives output at the time of implementation.

- To the implementation of the operation, there are some steps that are described here.

- First of all, the pressure, temperature switches, and pushbutton inputs are inspected and their position is documented in the memory of the controller.

- The contact which is open is stored in memory as O and closed contact stored a 1 (one).

- Then ladder circuitry is monitored with every inner connection assigned as open (o) or closed (1) rank according to its 1 or 0 conditions.

- When the conditions of the input links offer logic stability from leftward to right along the ladder, the output coil storage position is assigned a logic 1 (one) and the output unit interfacing links will close.

- When there is no logic continuousness of the program ladder, the output coil storage position is set to logic 0 (zero) and the output component interfacing links will be open (0).

- The accomplishment of one round of this arrangement by the controller is named a scan.

- The scan time, is the time required to complete one rotation, delivers a measurement of the speed of reply of the Programmable Logic Controller (PLC).

- Normally, the output storage position is reorganized through the scan but the real output is not reorganized till the finishing of the program scan through the Input, Output scan.

Working of Fixed PLC Modular

- In the last heading, we discuss how a ladder logic program makes and how it works. Now we discuss plc fixed modular connection and assembly of ladder logic program.

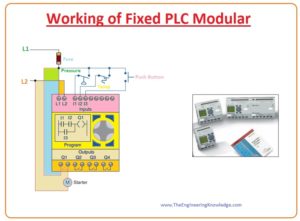

- Given diagram shows the distinctive cabling essential to implement the process control arrangement by means of a fixed PLC regulator.

- In this example, the plc controller furnished with 8 (eight) inputs and 4 (four) outputs is used to switch and observe the procedure.

- The connection of this plc module is described below.

- Power lines consisting of fuses of definite voltage categories and level are associated with the L1 and L2 connections of the controller.

- The input field components like pressure, temperature switches, and push-buttons are connected by the wire among the L1 and I1, I2, I3 which are the input terminals of the controller.

- The motor starting coil links with the L2 and in sequence with Q1 relay output links to L1.

- After this connection, we can put our ladder logical program by using the keypad on a controller and can see program on an LCD display.

- Guys till now we have learned about working of plc and its ladder logic construction. But if sometimes we want to change or modify or ladder logic program which we create using plc.

- Can we change this circuit? Or can we modify it? For these questions, we discuss how we can modify plc operation. And also discuss its comparison with the relay logic. Mean what we should do if we want to relay logic circuit.

How to Modify PLC Operation

- Plc has many features but one of the main features is that we can easily modify our written program.

- First of all, we discuss it in the case of relay ladder logic.

- Let’s suppose that we have to modify process control circuitry which we discussed earlier.

- In a given diagram, we can see that alteration which has is if we want to control our process by only a temperature switch for this we have to change our wiring which is a very difficult task.

- But in the case of plc, we will just change the program which we had already made and nothing else.

- From this, we can observe that it is very easy to modify our program in plc but in the case of relay it is no easy task. Modification for PLC shown below.

That is all about the working principle of PLC if you have any questions about part of plc you can ask in comments. See you in the next tutorial, Input and Output Section of PLC.

Very nicely explained Good

thanks dear

Incredible! This blog looks just like my old one!

It’s on a entirely different topic but it

has pretty much the same layout and design. Outstanding choice of colors!

I have read some good stuff here. Definitely worth bookmarking for revisiting. I wonder how much effort you put to make such a fantastic informative website.

Thanks , I’ve just been searching for info approximately this topic for ages and yours is the best I’ve came upon till

now. But, what in regards to the bottom line?

Are you certain about the source?

Like!! Great article post.Really thank you! Really Cool.

thanks for you best article

I read full text its helps me a lot