Hello, readers welcome to new post. Here we will learn What is PCB Baking. For the creation and use of PCB board PCB baking is considered a very significant module. The older techniques used in industry were not so optimized but PCB gives new life to industry since can be created in small size boards and less prices devices. PCB is considered as a significant part of industry. Each device used in electronics such as phones, tablets and larger projects is created on the board.

Hello, readers welcome to new post. Here we will learn What is PCB Baking. For the creation and use of PCB board PCB baking is considered a very significant module. The older techniques used in industry were not so optimized but PCB gives new life to industry since can be created in small size boards and less prices devices. PCB is considered as a significant part of industry. Each device used in electronics such as phones, tablets and larger projects is created on the board.

It must not be needed to consider PCB boards prefer to standards and installation of surface mounted. There are different PCB manufacturers working in the world the create the board and perform the baking of PCB accurately. But one of the best in all services that offered the PCB based services with PCB assembly services at single places with great quality. PCBWAY with their business of PCB board their PCBA services also has a high-quality specialty in prototyping and small volume manufacturing enhancing the PCBWAY one stop destination features for their customers. This feature helps your research and development process be simple and less time taking. Their highly trained and well-equipped engineers work collaborate to you through their customer support services and high-quality features and needed lead time interval.

Fulfilling thousands of orders daily from around the world, they have established themselves as the leading supplier of PCB and PCBA services for our consistent quality and excellent services. They also offered the SMT Assembly, BGA Assembly, Through-Hole Assembly, Mixed Assembly, and Rigid-Flex PCB Assembly Services. Compliant with a wide range of standards including IPC 610 Class 2 and Class 3

Introduction to PCB Baking

- To eliminate the moisture from the manufactured PCB board is called PCB baking. Condensation can occur if the surface of the board is cooler than the air around the board.

- As a result, moisture is absorbed by the PCB board lamination substances. Is some quantity of moisture exists in the board ca cause serious problems during the PCB manufacturing process cause serious problems for circuitry.

- The quantity of moisture absorbed by the board relies on the laminated material employed in the PCB board.

- The use of polyamide flexible and rigid material has the ability to absorb larger moisture than the FR4 board.

- During the baking process, PCB is placed in the oven at a temperature of one hundred to one thirty centigrade.

- Heat existing in the oven helps moisture to dry out. During baking sustain the temperature value that can not damage the board.

Importance of PCB Baking

- Baking PCB board helps to avoid the condensation that occurs in the cooper plating coated on gaps and to avid the outgassing.

- It causes the pinholes to blowholes during the soldering processing. Baking of boards also reduces the delamination of the board during the soldering.

- During the drilling connection between the glass fabrics and epoxy can be disturbed which can affect the board quality

Do all PCB boards need Baking

- Elimination of moisture from the PCB board during manufacturing is significant for all manufacturers. For this purpose, a baking board is done

- If moisture is not removed properly in the board then it saves in the devices can damage the board’s function and structure.

- Sometimes no baking is done but moisture removes from the board directly.

- This process must get at the design of PCB board and manufacturing process. PCBWAY performs these tasks very accurately so their boards are works fine and have long time intervals. Also, get high-quality boards and results.

- Condensation sometimes causes problems on the basis of PCB design.

- Value of temperature regulation done during the PCB lamination process.

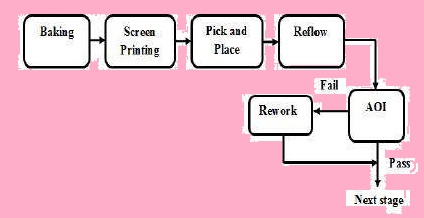

PCB Baking Process

- There are some points that must keep in before baking the board. If the board is manufactured accurately and closed for two months then no need to bake it.

- Also board is created in 5 days no need to bake it. SO if the board is open and put in a certain moisture condition than need to bake it and some steps are followed to do it.

- When the board is stored for five to sixty days then bake it for 2 hours.

- Board covered for two to six months bake for two hours

- SIx to twelve-month board save bake for four hours

- While board stored for more than twelve month is not considered for uses

That is all about the baking of PCB board this features helps us to use the board with great quality and less damages for our projects. PCBWAY also follows this process to avail the high-quality boards to their customers. Thanks for reading have a good day see you in next post.