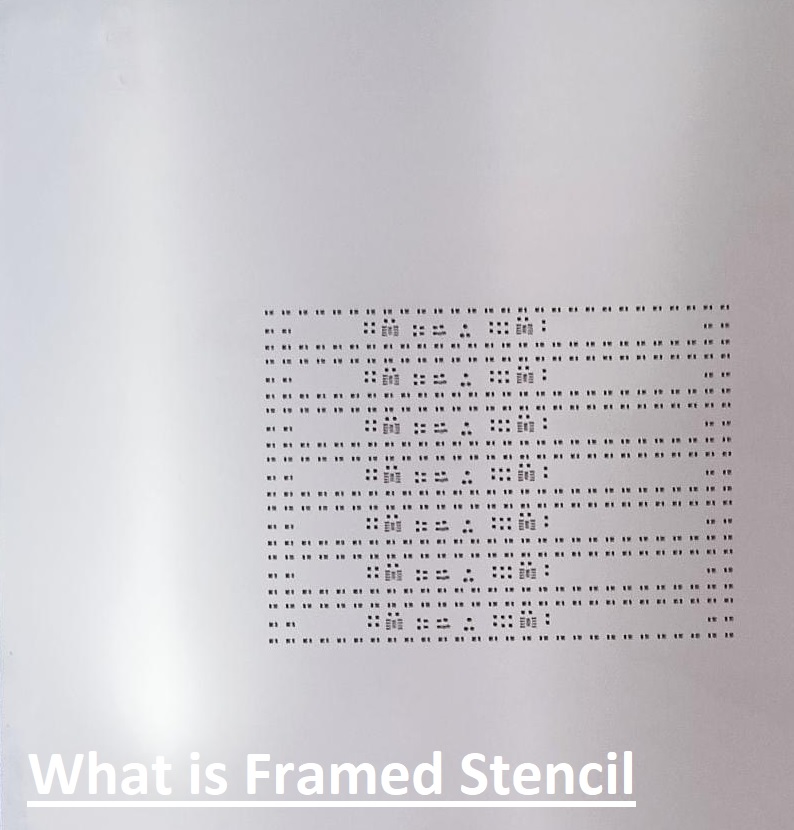

A framed stencil is a solder paste stencil that is used for the SMT assembly process and comes with laser-cut stainless steel foil configured on an aluminum or steel frame. A framed stencil is an important type of stencil that is used on boards; it provides consistent alignment and accurate solder paste application and is used for high-volume production. Here we will cover details for the framed stencil and related factors. So let’s get started.

What is an SMT stencil?

- An SMT stencil is a thin metallic sheet used for the soldering process in surface mount technology, which is important for the SMT soldering process.

- An SMT stencil provides a direct connection of solder paste on SMD board pads that avoids errors at the end of the reflow soldering process.

- As a result, we get an accurate amount of tin coverage after finishing the operation.

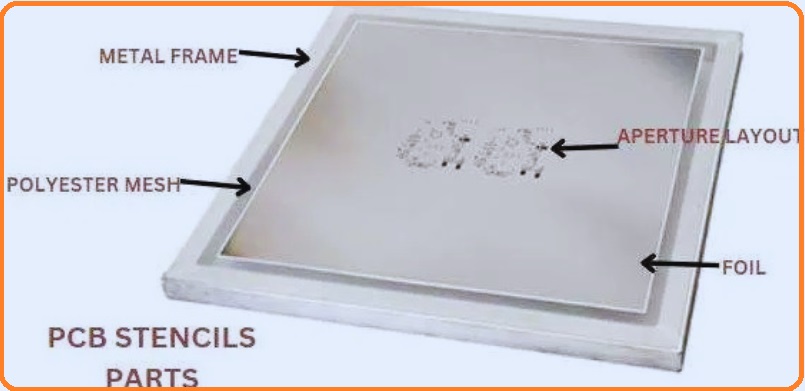

Manufacturing Process of PCB Stencil

Different methods are used for making PCB stencils. explained here

Materials selection

- For stencil manufacturing, first point out locations where surface mount components are connected and make a design for the PCB stencil. After finalizing the design, a stainless steel sheet is used as the raw material. with that nickel, polymer, or plastic material used according to project demand

Cutting the Holes

- accurate apertures made on the PCB stencil through applications of different methods. Laser cutting is used for making holes that use a high-power laser beam to cut an aperture pattern according to a stencil foil.

Stencil inspection

- PCB stencil clean for clearing remnants during the aperture process. Proper quality inspection is made by PCB designers and engineers to ensure that pastes are applied in the proper quantity for the printing process.

Stencil Framing

- for making a framed stencil, frame it using a strong material for accurate alignment and fix it properly. This step is not used for frameless PCB stencils.

Stencil Printing

- Stencil applied on the upper surface of the board according to design requirements. After that, put the metal squeegee blade at the start of the printing process and apply pressure to press paste through apertures to the solder pads.

Maintenance

- Solder paste is not the last phase; manufacturers clean the paste and do proper checking according to standards.

Advantages of Framed Stencils

Durability

- The rigid frame prevents the stencil from bending, even after different prints. So framed stencils are preferred for high-volume SMT assembly where durability is important.

Accuracy

- Stencil surface provides uniform solder paste deposition that minimizes the chances of error. Constant applications of SMT paste provide good output rates by increasing production by 15 percent larger production.

Ease of Use

- The framed stencil has the feature of easy handling and alignment through automated printers, which reduces cost and minimizes errors.

Compatibility

- framed stencil operated with standard stencil printing machines, and is a reliable option for industries’ manufacturing processes

Disadvantages of Framed Stencils

High Cost

- Framed stencils are a high-cost process since they need extra materials and a manufacturing process for framing. It has 25 to 30 percent extra cost compared to a frameless stencil, according to applications.

Storage Space

- This stencil has a bulk frame that covers more area, which is not preferred for limited-area projects.

Less Flexibility:

- A framed stencil is a fixed frame; after construction, no design changes are possible, so if damaged, a new stencil is made, which increases cost.

When to Use Framed Stencils

Framed stencils are the go-to option in several scenarios:

High-Volume Manufacturing

- A framed stencil is preferred for making bulk volume boards on a daily basis, which makes it precise and durable.

Automated Assembly Lines:

- Automated stencil printers are used for framed stencils, and they are best suited for large-scale operations.

Complex Designs boards

- A framed stencil provides stability to accurately apply solder paste applications for boards that have fine-pitch component connections.

How to Choose an SMT Stencil?

SMT Stencil Thickness

Stencil thickness is the main factor for finding proper solder paste applications that are applied on board pads. At the time of stencil printing, the lower part of the stencil sheet was connected to the upper area of the board.

So stencil thickness helps to measure the solder paste thickness that is applied on the board pad.

- SMT stencil thickness is selected according to the components connected on the boards, the package type, and the spacing between pins. thin stencil used for small spacing. If the components on board are larger, a thick stencil is used.

- For the same boards, there can be general spacing components more than 1 mm and small space components. The thickness of the stencil is applied according to the connected components on the board. The best thing is that it reduces or increases the solder paste applied on the board by controlling the pad opening on the stencil. It can be set in PCB design software by adjusting the “Solder Paste” layer.

- If components need different solder paste quantities, use a thin stencil for narrow spacing parts. But the thinning stencil is high cost. So use the middle thickness options for stencil applications according to the solder paste.

- General pitch components use an opening in a ratio of 1:1. Larger components need high solder paste; the opening area increases by 10 to 20 percent.

SMT Stencil material

- Stainless steel and copper are used for laser-cut SMT stencils. Stainless steel has a longer working life, high strength, and good corrosion resistance. Copper is a good conductor and provides high efficiency. Stainless steel is commonly used for PCB stencils. since good features make it prominent

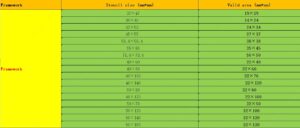

SMT Stencil Size

- SMT stencil size selected according to board size. The accurate size of the stencil sheet is used according to the shape and board spacing to reduce errors in production. The stencil size needed to have the size to handle larger board data in the proper stencil area, which was larger than the size of the stencil. The valid area defines the main area where the SMT pad is cut into the sheet, and the remaining area makes the margin of the stencil and is not cut.

Here you can get features and sizes provided at JLCPCB manufacturing services for framed stencils.

JLCPCB also provides PCB prototypes in the size range of 10×10 cm or less. If the current conventional stencil is applied, a larger part of the stencil sheet area is wasted, which makes it uneconomical.

JLCPCB not only provides framed stencils but also supports standard frameless stencils with pricing starting at $7 and the option to specify a custom outline.

To get the cost, upload the Gerber file and use the online ordering system, and you will be charged based on the customized size and different parameters selected for your specific stencil.

JLCPCB has a specialty for making PCB boards and PCB assemblies with SMT stencils. They are an older service provider and have experience making the best laser-cut stencils.

They are offering

- High-precision laser cutting t

- Accurate cutting of stencils

- proper aperture design so that the stencil conducts as the solder paste is released

- SMT stencils as thin as 0.10mm-0.30mm

How to Maximize Framed Stencil Performance in SMT Assembly

Different methods can increase the working life of framed stencils, like accurate handling and maintenance. So other methods are as

Cleaning

- It is preferred to clean the stencil after five to ten prints to minimize solder paste creation. For this purpose, a certain stencil cleaner is used with the help of a lint-free cloth to prevent dust and other particles from accumulating.

Storage:

- We can prevent warping frames through proper storage of framed stencils and store frameless stencils in protective sleeves to control bending.

Check Tension (for Frameless):

- For a frameless stencil, a tensioning system used smooth pressure on the foil. Uneven tension causes print faults.

Inspect for damage.

- Proper inspection for framed stencils finds dents and scratches in a timely manner to solve. since minor damage badly affects efficiency