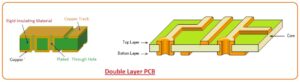

Hello, readers welcome to the new post. We will discuss What is Double-sided PCB. PCB stands for a printed circuit board that is mostly used in different types of projects and devices and comes in different structures. This board has a structure configuration such that the upper part of the board have copper layers, silkscreen, solder mask, and at last layer of the substrate material. Substrate materials are different types according to PCB design applications.

Hello, readers welcome to the new post. We will discuss What is Double-sided PCB. PCB stands for a printed circuit board that is mostly used in different types of projects and devices and comes in different structures. This board has a structure configuration such that the upper part of the board have copper layers, silkscreen, solder mask, and at last layer of the substrate material. Substrate materials are different types according to PCB design applications.

PCB boards come in different types such as single layer, double layers, and multiple layers. Each PCB type comes with different features and design configurations and is used in different applications. Today we will cover the details of double-sided PCB. so let’s get started

What is Double-sided PCB

- Double-sided PCB has two-sided conductive layers that means on two sides components can be connected to make the circuits

- The structure of these boards is somewhat more complicated than single-layer boards. It comes with single substrate material but has two layers for component connections. Also, have solder mask paste on both sides

- It has conductive holes on both sides of the board to connect electronic components. These holes are used for making the connection between the components attached at one side to the other side of the board. So it known as two layers boards

- The PCB construction technologies that are through-hole and SMT are both can use for this board to connect the components.

- These boards are configured for vending machines mobile phones circuits UPS, light systems, etc

- These boars are preferred for advanced project designs and circuits.

-

The PCB core of doubles-sided PCBs can be FR4, aluminum, copper, PTFE, AlN, alumina, etc.

Difference between Single-Sided PCBs and Double-Sided PCBs

- There are some differences between single and double-sided boards are explained below

Single Sided PCB

- These boards have conductive layers just on one side

- It used for simple designs and projects

- It is created for fewer density circuits arrangements

- Its repairing is easy since having a simple circuit

- It does not have the intersection of traces

- Its structure is less flexible for routing

- It covers larger areas.

- Its construction cost is less than the double layers boards

Double Sided PCBs

- It has a complicated design so repairing and troubleshooting is difficult

- It has the intersection and overlapping for traces

- Its flexibility for routing is high than single-sided.

- It used for advanced-level operations

- It takes more time for construction so less quantity is produced than the single layers

- It has two-sided conductive layers

Double-Sided PCB from PCBONLINE

- There are different PCB suppliers working that offered double-sided PCB services but PCBONLINE

- offers the single plate form for double-sided PCB, with the design of board manufacturing, assembly, and box build.

- They can provide the double-sided PCB with FR4 material, also AIN PCB, alumina PCB, PET PCB metal core PCB. The computer assistance manufacturing (CAM) engineer from PCBONLINE will provide free one-on-one engineering support throughout the project.

Double-Sided PCB Manufacturing and Assembly by PCBONLINE

- The construction of double-sided PCBs is not different from the layers of PCBs. But differences between their construction are listed here.

- For double-sided PCB double-sided laminate is used while for single-sided single laminate used

- For the construction of double-sided PCB, there is a need of drilling plating through holes and electroplating holes having copper

- There is a need for additional drilling and resing filling to insulate the metallic core and PTHS

- Double-sided PCB assembly needs SMT assembly two times, each time for assembly on one side.

PCBONLINE was established in 1999 that has 2 larger and more advanced construction units and one PCBA industry. For double-sided PCB you can get one-stop services from prototyping to bulk production from the PCBONLINE.

Here are some features of PCBONLINE for double-sided PCB can see.

- From PCBONLINE you can some characteristics for double-sided PCBs that are listed here

- Good manufacturing capabilities

- Double-sided boards from two to sixty layers

- Thickness for copper is 1/3oz to up to 14oz also high density can get

- There are different categories of double-sided PCBs that can be got as FR4, PTFE, aluminum, copper, PI, PET, ceramic, and hybrid substrates.

- Double-side PCB manufacturing and assembly, including electronic components, certified with ISO, IATF, IPC, RoHS, REACH, and UL

- double-sided AlN PCB from PCBONLINE can see here

Further details related to double-sided PCB from PCBONLINE can get here

Double-Sided PCB Advantages

- This board comes with two sides for component mounting that helps to connect larger components for project creation.

- These boards offered larger areas for circuit construction and larger design features. As compared to the one-sided boards these boards have a small size with similar features that advantage over single layers

the challenge for double-sided PCBs.

- The substrate used in these boards is at interlay side of the PCB with larger components so can get overheated. PCBONLINE is equipped with trained staff and machines to solve this problem. For this, they parted the thermal dissipation and electrical system to manage the heat

Double-Sided PCB Applications

- Common applications of double-sided PCB are listed here

- Used in vehicle dashboards

- Used in printing machines

- Used in mobiles phones

- It is part of vending machines

- Traffic signals have these boards

- The power supply consists of this board for circuits creation

- HVAC uses this board

- UPS used this board

That is all about the Double-sided PCB all details have been explained about the Double-sided PCB. Further must visit te PCBONLINE to get the quality boards thanks for reading have a nice day.