Hi, readers welcome to the new post. In this post, we will have a detailed discussion about Advanced PCB. PCB board is the most important component of every electronic device and project that we are commonly using. it has become very common to us and now can see it practically in each electronic device circuitry that is assembled on that board. According to use and structure there are numerous types of PCB such as single layer PCB, double layer PCB, multiple layer PCB, rigid PCB, and some others.

Hi, readers welcome to the new post. In this post, we will have a detailed discussion about Advanced PCB. PCB board is the most important component of every electronic device and project that we are commonly using. it has become very common to us and now can see it practically in each electronic device circuitry that is assembled on that board. According to use and structure there are numerous types of PCB such as single layer PCB, double layer PCB, multiple layer PCB, rigid PCB, and some others.

All these types of PCB board has its own use and applications according to requirements. They are employed in different applications like medical devices, industrial instruments, aviation, and other fields of life. Like these types of PCB board, there is one another category of PCB that now also has become common to us and now using in different applications. Which is advanced PCB in this post we will cover its applications, uses and some other related parameters. So let’ get started with Introduction to Advanced PCB.

Introduction to Advanced PCB

- The advanced PCB circuitry board is has a complicated structure and has numerous layers as compared to the normal multiple layer PCB.

- It is part of electronic devices that needed a high level of precision with high-end complicated circuitry like different industrial devices, automotive, aviation.

- With that, it also employed in communication tools, complicated computing circuits, automotive circuits, as well.

- With the advancement in technology, there are different Rocks Satellites are launched by the scientist to move to the Moon and another universe.

- So to design these devices there is a need off complicated computing and high-level electronic instrumentation that is not can get through the normal PCB board.

- So do all this high-level work there is a need to use advanced PCB that can handle these complicated circuit design and manufacturing.

Advanced PCB Manufacturing and Desing

- The construction of advanced PCB is like the normal PCB and its other categories. Like other PCBs there is standard of IPC-2221A is followed for this board.

- To design this board there is usage of an eagle and other PCB design software for this board.

- Any designer of this board just the proper grip of this board assembly and know how to make it useful for proper application.

- The manufacturing process for this board is like the multiple layer board that with some precaution is that there should be chosen of accurate substance to make this board accurate for design.

- For practical use of this board in electronic elements and devices, there is restricted usage. Ther is the usage of wave soldering is used for this board with the accurate model of accuracy.

Advanced PCB Manufacturer

- There are numerous PCB suppliers and manufacturers are working in this world but the most reliable and trustable with good quality PCB and Advanced PCB manufacture is PCBWAY.

- It has a lot of experience in the creation of products with high speed and accuracy and reliability advanced printed circuit board.

- They offer services related to design, choosing good material, prototypes with that integrity analysis.

- This manufacture has a high-level engineer and technologies team to assist you and also helps to make affordable products and with high performance.

- To order advanced PCB from this PCB manufacturer just click here.

- The advanced PCB of this manufacture has sixty four-layer with a trace size of 2.5/2.5mil given hole dia of 16/1

- They are certified with UL and ISO9001:2008.

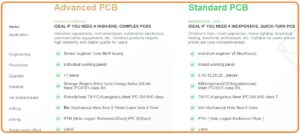

Comparison between Advanced PCB and Standard PCB

- The parameters related to advanced PCB and standard PCB are mentioned here.

- The main services related to advanced PCB offered by PCBway can be seen here.

Advanced PCB Applications

- The main applications of this board are mentioned here.

- It used in different medical devices like X-ray machines.

- it used in the creation of LED circuits.

- Used in aviation.

- Employed in different industrial instruments.

- Automotive elements are designed through this board.

That is a detailed post about advanced PCB i hope you enjoyed this post. Thanks for reading. I tried to cover all details related to advanced PCB if you has any further query ask in the comments. Thanks for reading.