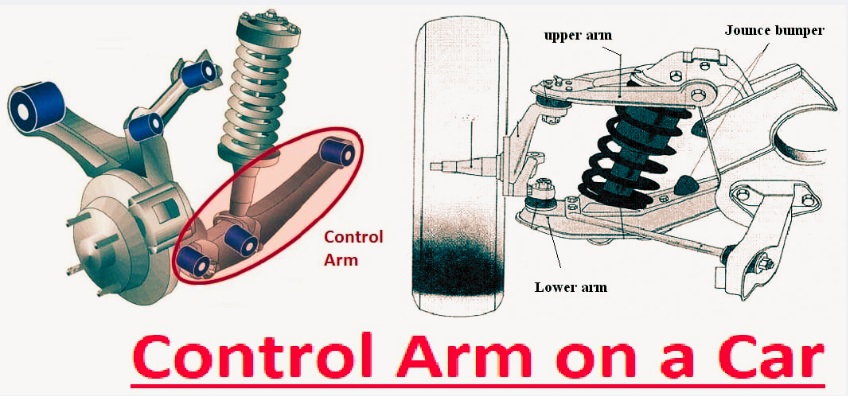

Control arms are the main part of the vehicle’s front suspension system. Basically, control arms are linking points that make a connection between the front wheels of the car. One end is configured with a wheel assembly, and the other end is connected with the car framework. The control arm comes in two categories: the upper control arm connected with the top part of the front wheel and the lower control arm connected with the lower, larger part of the front wheel. after that second connection of both arms with the car frame. This structure also applied for independent rear suspension.

In this post we will cover features of the control arm, types of working, and importance in the car suspension system.

What is a Control Arm of Car?

- In a vehicle suspension control arm, another name is A-ARM, which is the hinged suspension connection between the chassis and the suspension hub where the wheel is configured.

- Its function is to manage the vertical movement of the wheel, which helps the wheel to move up/down when facing bumps or rough roads.

- Some control arms armsmakes a lower connection or link of suspension. so considered as the main part of the vehicle suspension system. because it makes proper tire contact on the road through accurate wheel alignment that provides safe driving.

- The chassis end of the control arm is connected through a single pivot with a rubber bushing. It controls the outboard end position in one movement through maintaining radial space from the inboard mount.

- It does not move freely; a single bushing does not manage the arm’s back-and-forth motion, which is managed through separate link or radius rod.

- control, also called wishbone due to its A-shaped design. It also comes in L-shapes and straight shaft layouts.

- Older types of ofvehicles that are designed with double wishbone suspension come with two arms for a single front axle wheel. that are called upper and lower arms.

- Now advanced cars are working with MacPherson suspension. In these vehicles, a suspension strut is used in place of an upper control arm, and just one lower arm is on any axle side.

- In SUVs and trucks, suspension struts are used on the rear axle.

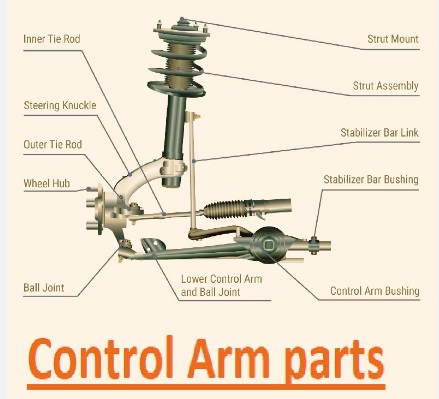

Control Arm parts

The control arm comes with a structure where the ball joint is connected on the end that is configured with the wheel hub and the bushing end connected with the chassis. main parts of control arm areas

Arm Body

- body of control arm made with different material like steel, cast iron, and aluminum. It is the main part that exists between the mounting of the assembly end.

Bushings

- Bushings make arm connections with the vehicle structure. that prevent friction through avoiding connection between the metallic surface of the arm and the chassis.

- Bushing also helps to damp chassis vibrations during up-down movement of the vehicle on rough roads for smooth driving. Some bushing comes with replacing features; some are not replaced.

Ball Joint

- Ball joint parts are used for making connections between the body and the wheel assembly and suspension. It causes suspension up-and-down movement and rotation of the steering knuckle.

- Ball joints are replaceable or permanently connected. for avoiding metal-to-metal contact, a polymer insert between the socket.

Control Arm Function

- The control arm function is simple: it makes a connection between the steering knuckle with the frame and maintains vehicle stability through uniform movement of wheels and chassis during driving.

- So control arms provide suspension and steering system coordination for easy vehicle turning.

- control arm ball joint is like steering pivot point, that provide vehicle turning in any direction.

- A hinge joint ofcontrol arms exists on the frame side, making a strong wheel connection with the withground, matter which type of road you are travelling.

- For safe movement of the vehicle, both control arms operate with the same configuration for safe driving.

Control Arms different types

The types of ofcontrol arm defined according to the locations of connection points and length-changing features. common types of control arms as

Upper & Lower Arms

- upper control arm connected with suspension and frame. They employed a conventional double wishbone suspension. But some advanced vehicle types do not use upper arms but use strut suspension.

- lower control arm type connected with lower part of wheel assembly. that can easily handle weight and is part of all vehicles, also new, that comes with strut suspension.

Front & Rear Arms

- front control arm connected with front axle. Double wishbone suspension comes with two control arms for each axle side, and MacPherson suspension comes with one arm.

- SUVs and trucks and some other heavy-duty vehicles use rear control arms. Controllers on these vehicles, either front or rear, provide smooth driving.

Adjustable Arms

- These arms have variable length features and are best for threaded parts. They preferred it since it helps to set tire camber. For replacement of ofarmsand changing alignment, these types of arms are best to use.

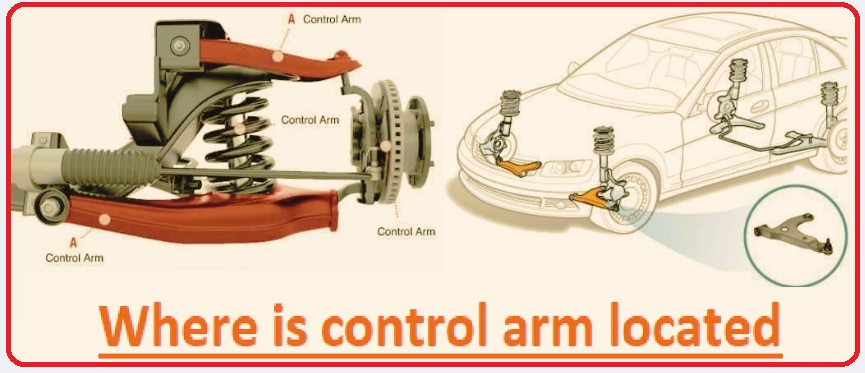

Where control arm mount?

- For accurate working of the control arm, its connection locations are an important factor.

- Normally, the control arm is connected with the vehicle frame through a pivot bushing on one end and the other end connected to the steering knuckle through a ball joint

- A control arm works like a bridge, close to the central point of the vehicle. The control arm is connected with the vehicle’s chassis or a subframe. This connection is made with specially designed rubber or polyurethane bushings.

- Bushings perform two functions: during rough or bumpy on-road driving, bushings absorb road vibrations for safe driving.

- For the outboard side, the control arm is connected with the steering knuckle. where the ball joint makes the connection

- Ball joints are spherical bearings that cause pivoting of the steering knuckle for forsteering and also handle any variation in suspension movement.

How do control arms work?

- The control arm has a connection through two control arm bushings with the vehicle frame. These pushings provide up-down movement of the control arm.

- control arm both endconnected withsteel spindle. spindle point where the front wheel is bolted, non-strut vehicles, spindle connected with upper and lower control arms to ball joints.

- Ball joint steel made ball covered with a steel socket that causes rotation of the spindle and front wheel rotation left and right and the vehicle to move easily on rough roads.

- A high-weight steel coil coilspring exists between the control arm and the vehicle frame, configured in a spring socket that maintains the weight of the vehicle and provides a cushion for bumps.

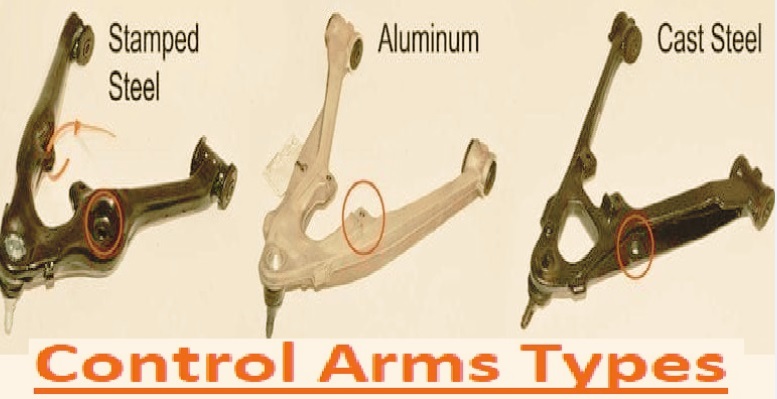

Control Arm construction Material

There are different materials used for making control arms; each has its hasitsown features. some common materials used for usedforconstruction control arm areas

Stamped Steel

- steel comes with a sturdy and flexible design and does not break when facing high impact or weight. Steel arms have a low-cost manufacturing process that makes them a low-cost option.

- But its disadvantage is that steel is affected by rust in wet conditions. for avoiding rust on a steel structure coated with a protective coat

Cast Aluminum

- Aluminum has a low weight and does not add extra weight. It is also not affected by rust and works well in moist conditions. It also has better features for vibration management.

- Cast aluminum has features for handling weight. but its rigid nature causes its breakage when facing high force. It also wears fast.

Cast Iron

- Cast iron has high rigidity compared to steel and aluminum and also manages high loads. Cast iron arms are part of trucks and some other heavy-duty vehicles.

- Cast iron also gets corrosion with time. so it needed coating for providing protection from wet conditions.

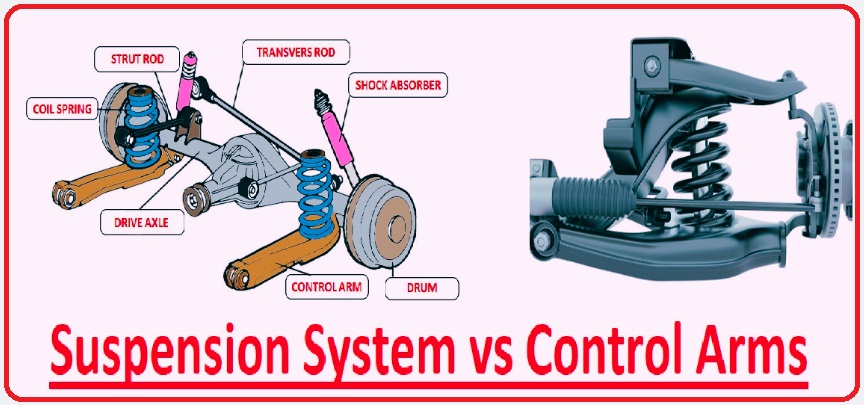

Difference between suspension and control arms

Suspension

- A suspension system is a complete assembly that makes a connection of vehicles with wheels and controls certain parts of the suspension system. Control arms and hinged links connected to the wheel and made movement based on the chassis.

In other words, a complete suspension system comes with different parts for performing different operations.

- It manages vehicle weight, eases vibrations, and absorbs the road surface for safe driving.

- It maintains tire connection with the road for easy braking and strong grip.

- It also controls the vehicle and makes the makesteeringprocess safe.

- The suspension system comes with different parts like springs, shock absorbers, linkages, ball joints, bushings, and wheel hubs.

Control arms

It is part of the suspension and makes a connection between components in the suspension system. It makes a connection between the wheel assembly and the frame of the offrame control wheel position and movement.

Importance of Control Arm Location

The mounting point of the control arm is important, since its location and design define the complete handling of the vehicle. Control arm location helps to make an accurate suspension structure and also affects features of steering caster and camber.

Any minor fault or change in arm location causes tire wear.

location of control The arm pivot point is considered important for chassis design. some factor areas

Camber Control

- For the double wishbone system, the upper control arm is short compared to the lower arm, which makes camber gain. When the car moves into a corner and the suspension compresses, the upper side wheel is inwards pulled, making tire contact on the road for a strong grip. if the control arm at accurate points causes this process accurately

Caster

- The fore and aft position of the control arm is configured on the chassis for finding the caster angle of the steering axis. Accurate casters provide stability of the vehicle during driving, and the steering wheel moves to point after completing turning.

Scrub Radius

- The design of control arms and ball joints is scrub radius, that is, the distance between the steering axis pivot point and the middle of the tire contact patch.

- that affect the steering process and how the car shows signs for braking on split friction surfaces.

- A bent control arm through colliding with a pothole is not good. that affect designing and cause accurate handling of high-speed tire wear.

Sign of Bad Control Arm

Uneven Tire Wear:

- Faulty control arms result in a change in vehicle alignment, which means tire wear is nonuniform. If tire wear is increasing fast, that means the control arm is not working well.

steering wheel vibrations

- A damaged control arm also causes vibrations on the steering wheel during turning, mostly observed

Steering wandering:

- During driving, the vehicle does not move straight on a single level, and on straight roads, it causes wander, which is also a sign of control arms.

Clunking noise:

- Clunking noise is produced when ball joints are damaged or become loose, especially during turns.

Poor handling

- If the vehicle is showing improper handling when we steer, that is also a sign of faulty control arms.

How much is the replacement cost of a control arm?

- Control arm assembly cost is in the inrange of 60 to 300 dollars. normally cost-based on arm design, vehicle type, and manufacturing.

- Aluminum control arms are costly, and stamped steel is low cost.

- The control arm comes with A and L designs, so before replacement, choose according to vehicle requirements.

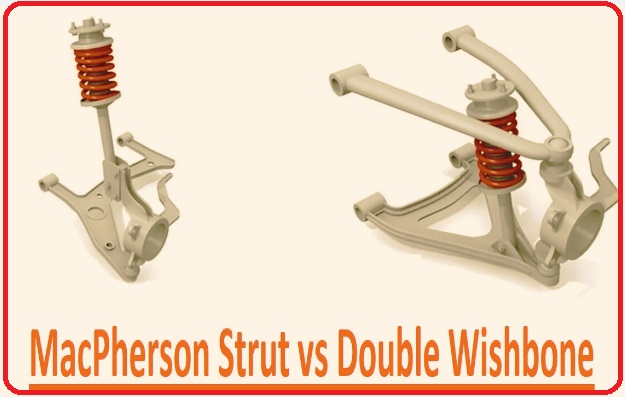

Wishbone or Double Wishbone vs MacPherson Strut

Wishbone or Double Wishbone (A-Arms):

- This design comes with two control arms of the suspension assembly, one upper and one lower. Each arm comes with two mounting connections on the frame, and one exists on the wheel hub that makes the wishbone structure.

- This design provides good control for wheel movement and makes accurate stability. The double wishbone design is preferred for high-performance cars for providing accurate wheel motion control.

MacPherson Strut

- In this design one control arm exists, that is, the lower control arm, and in place of the upper control is a MacPherson strut.

- • A strut exists on the vehicle body at the upper side, and a control arm exists on the lower side. It is a simple design and low cost, with a cover that takes up little space and is employed for passenger vehicles.

- Either its working performance is low compared to the double wishbone design, or it works well in normal driving.

- Control arms also alsocomes with two types but come with different designs according to vehicle design.

- in multi-link suspension that has many control arms for good movement

How Long Do Control Arms Last?

- Control arms do not come with a special replacement time. Since different factors define the working life of a control arm, they are vehicle mileage, age, driving conditions, and operating condition.

- Control arm structural features affect working life. Different vehicles use control arms that are made with features of low-cost options and make features that can handle corrosion for a longer working life.

- Heavy-duty trucks use forged steel control arms that face low corrosion.

- High-performance cars use cast aluminum control arms. The aluminum control arm’s low weight has high corrosion resistance and a long working life for the vehicle.

- Aluminum control arms are low weight, have high corrosion resistance, and have a longer working life.