The selection of an accurate wire gauge is important for the safe operation of a circuit and for working performance. 12-gauge wire can handle different loads. So the ampere rating is important for current handling features for accurate working of the system. In this post, we will cover detailed features of 12-gauge wire amps and their effects on circuits. So let’s get started.

What Is 12 Gauge Wire?

- 12-gauge wire is a commonly used conductor for lighting wiring and residential applications. Its thickness is 0.081 inches and comes with good strength and a flexible design.

- Its thickness is higher compared to 14 AWG wire and thinner compared to 10 AWG that is preferred for 20 amp circuits.

- It is part of lighting, outlets, and small devices since it handles medium loads in enclosed spaces and through walls.

- This wire is made with copper or aluminum, but copper is commonly used since it has good conductivity and corrosion resistance.

- Its structure is such that it can handle a 2400-watt load for a 120-volt system. It is part of the receptacles’ wiring and lights circuits and operates different devices like dishwashers and refrigerators.

What Are The Amps For 12 Gauge Wire?

12 AWG cable is part of indoor wiring circuits like outlets and applications where about 20 amps of current are needed. 12 AWG copper wire ampacity for different types like 12/2, 12/3, and 12/4 is in the range of 20 and 30 amps.

Based on insulation, 12 AWG wire current-carrying features are as follows:

| Wire Size | Conductor Material | Insulation Rating | Insulation | Ampacity |

| 12 AWG | Copper | 60°C | TW, UF | 20 Amps |

| 12 AWG | Copper | 75°C | RHW, THWN THHW, | 25 Amps |

| 12 AWG | Copper | 90°C | THHN, XHHW | 30 Amps |

12-Gauge Wire Ampacity

- Ampacity rating for 12-gauge wire is 20 amps in general applications. These values are according to NEC requirements, assuming copper wire working at 60 degrees. ambient temperature of site locations and insulation used, and wire bundling affects ampacity

- Ampacity safely defines current-carrying capacity. Different factors affect wire ampacity, like the conductivity of materials like copper, which carries high current.

- Another factor is size; thick wire has high ampacity.

Ampacity of 12 AWG Aluminum Wire

Aluminum provides lower conductivity compared to copper, which affects 12 AWG aluminum wire ampacity.

| Wire Size | Material | Insulation Rating | Insulation Types | Ampacity |

| 12 AWG | Aluminum | 60°C | TW, UF | 15 Amps |

| 12 AWG | Aluminum | 75°C | RHW, THHW, THWN | 20 Amps |

| 12 AWG | Aluminum | 90°C | THHN, XHHW | 25 Amps |

Factors Affects Ampacity

Different factors affect ampacity for carrying high current loads without exceeding temperature values. different factors are as

Temperature

- The temperature wire installed is an important factor. The conductor connected in high-temperature installation does not dissipate heat well. Like 30 amp wire for a 25-degree ambient temperature rating connected in an area where the ambient temperature is 104°F (40°C), the conductor becomes de-rated for high-temperature conditions, so following the required conditions, we reduce fire risk.

Ambient Temperature | 12/2 (THHN) | 12/3 (THHN) | 12/4 (THHN) |

| 30°C | 30A | 30A | 30A |

| 40°C | 27A | 27A | 27A |

| 50°C | 24.6A | 24.6A | 24.6A |

Conductor Size

- High current-carrying features mean low resistance for larger conductors. With that material, also important like aluminum or copper. Copper provides high conductivity and carries high current compared to aluminum with the same dimensions.

- Such as 6 AWG copper wire has a rating of 65 amps, and an aluminum conductor of the same size has a rating of more than 50 amps.

| Wire | Copper Ampacity | Aluminum Ampacity | uses |

| 12/2 | 20A | 15A to 17A | branch circuits |

| 12/3 | 20A single conductor | 15A to 17A | provide red-hot wire |

| 12/4 | 20A for single | 15A to17A | Four insulated wires |

Insulation

- Insulation is also an important factor in wire temperature conditions. THHN insulation has features to operate at 90 degrees, and NM-B insulation rating is 60 degrees. It is important to consider factors for selecting wire insulation according to temperature and safe working demand.

| Insulation | Temp | 12/2 Ampacity | 12/3 Ampacity | 12/4 Ampacity |

| NM-B | 60°C | 20A | 20A | 20A |

| THHN/THWN | 90°C | 30A | 30A | 30A |

| XHHW | 90°C | 30A | 30A | 30A |

conduit fill

- Wires bundled in conduits cause heat increases since the heat dissipation capacity reduces. So the rating factor is important for these applications. If the current-carrying conductors of the conduit are more than 3 in results Current capacity reduces according to wire number.

Length run

- • A longer wire run causes resistance for voltage losses compared to a short one. For managing these factors, thick wire is used for longer runs, that make voltage losses less than 3 percent.

Environmental conditions

- Wire installed in difficult conditions, like heat and moisture conditions, required a certain insulation type to minimize the derating effect. Commonly used insulation that provides UV resistance and is waterproof is employed for outdoor circuits.

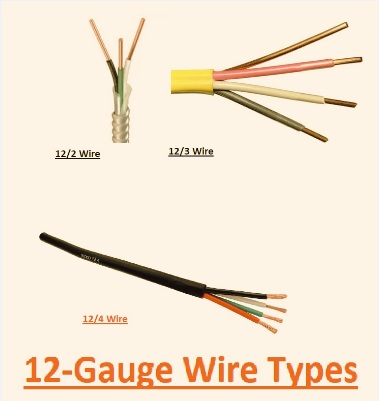

12-Gauge Wire Types

The number written with the wire size gauge defines the number of wires in the cable. That also defines insulated wire numbers. Some different types of 12-gauge wires are as follows:

12/2 Wire

- This wire comes with two insulated conductors, like one black that is a hot wire and the other white as a neutral, and it has a green ground wire. This wire is commonly used for standard120 volt circuits like lights and outlets

12/3 Wire

- 12/3 wire comes with 3 insulated conductors that are white, black, and red with a ground wire. The other helps to use in multiple ways with switch wiring in a 240V system where two live wires are needed.

12/4 Wire

- It has 4 conductors: red, blue, white, black, and ground in an insulated design. A 12/4 wire is part of a complicated design. Normally part of three-way switch wiring and four-way switch wiring, also part of 240V devices where different live wires and neutral wires are needed.

here we have made comparsion chart for different 12 gauge wires.

| Wire | Ampacity | Conductors | Temperature Rating | Length | Ampacity |

| 12/2 | 20A | 2 insulated,1 ground | 60°C to 75°C | 100 feet 20A circuits | 20A |

| 12/3 | 20A | 3 insulated,1 ground | 60°C to 75°C | 100 feet 20A circuits | 20A |

| 12/4 | 20A | 4 insulated, 1 ground | 60°C to 75°C | 100 feet 20A circuits | 16A (80% derating |

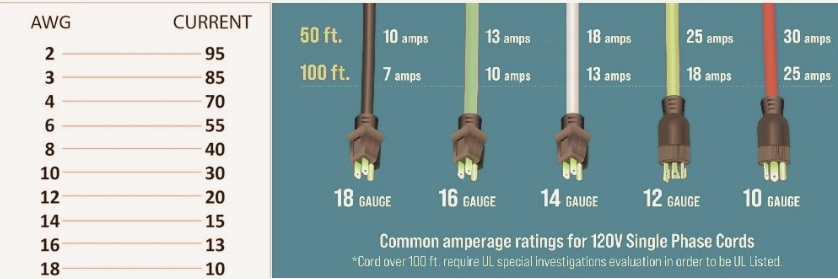

Some common Wire Sizes

| Amperage Capacity for Standard Non-Metallic Cable | |

| 16-awg | 13 amps |

| 14-awg | 15 amps |

| 12-awg | 20 amps |

| 10-awg | 30 amps |

| 8awg | 40 amps |

| 6-awg | 55 amps |

| 4-awg | 70 amps |

| 3-awg | 85 amps |

| 2-awg | 95 amps |

12Amp wire cable types

THHN/THWN:

- This wire is used in residential and commercial applications for operating wiring of light fixtures, small devices, and outlets.

NM-B Romex

- This cable type is used for residential indoor wiring projects like standard lighting circuits, outlets in dry conditions

UF-B

- It is direct burial wire in outdoor applications like garden lights, providing power to detached garages.

XHHW:

- This wire is used for moisture-resistant applications and heating management.

MC (Metal Clad):

- 12 AWG MC cable is part of industrial and commercial wiring systems, lights, and control circuits since it provides circuit protection with a metallic sheath

TECK90:

- It is a strong design cable part of industrial machines and power distribution circuits. This cable part of harsh environments.

Speaker Wire:

- 12awg speaker wire is a longer cable run with high power audio system applications

Applications of 12 amp Wire

12-amp wire is used for different applications based on requirements.

Residential circuits

- For residential circuits, 12-gauge wire is part of different applications like light fixtures and outlets. It is preferred for 20-amp circuits that are part of kitchen device circuits and bathroom outlets. The thickness of this thiswire helps to manage load without overheating.

Lights Circuits:

- This wire is part of indoor and outdoor light circuits. It has features to carry current for making connections of different fixtures over the same circuit.

- When connecting light circuits, this wire provides continuous operations

Small devices

- Different devices like toasters, microwaves, and air fryers are operated with 20-amp circuits. 12-gauge wire is best to provide effective power for home appliances without overloading circuits.

Vehicle Wiring

- This wire is also part of the vehicle’s electrical circuits and wiring, where different components like stereos and lighting systems are operating. The wire has good flexible features and current-carrying ability for different devices to avoid operation without voltage losses.

Solar power circuit

The solar system circuit also uses 12-gauge wire for making connections of solar panels with the inverter and batteries. Its thickness level helps to carry current through reducing energy losses and is preferred for mid-level solar systems.

Low voltage circuits

- This wire is also part of low-voltage circuits, like doorbell circuits and lighting system thermostats. It causes system current carry for smooth operation.

How to calculate Amp Rating of 12-Gauge Wire

- Different factors help to find the amp rating of 12-gauge wire. The main factors are wire material, insulation, and installation conditions. In copper conductors, 12-gauge wire with a 20-amp rating is used for circuits according to the National Electrical Code (NEC).

- Ratings are reduced for bad conditions like ambient temperature increases, and many wires are in the same conduit.

- Insulation is the main factor for dampening capacity. Such as THHN insulation has the highest temperature rating of 90 degrees, causing current at high amp values.

- Insulation like XHHW protects environmental features

| Insulation | Temperature | uses | operation |

| THHN | 90°C | Indoor circuits | High amp levels, dry conditions |

| XHHW | 90°C | Outdoor projects | Environmental protection, |

| NM-B | 60°C | Residential wiring | Standard household application |

12-Gauge Wire vs. 14-Gauge Wire

- wire sizes of either 14 gauge or 12 gauge based on current-carrying capacity and based on applications. 12-gauge wire has high thickness and carries a current of about 20 amps according to the circuit. high-demand circuits, employed for kitchen device circuits.

- 14 gauge is thin wire that can carry 15 amps, part of lighting circuits where low power is required.

- Their selection is also based on cost, durable features, and connected load.

Ratings of 12-Gauge vs. 14-Gauge Wire

- selecting wire for circuits with a rating of 12-gauge and 14-gauge wire based on safety measures. The accurate wire used comes with a 20 rating, like 12 gauge. High current required circuits are the kitchen outlet AC units. For carrying high loads effectively without overheating, larger wires are used for small loads, where low energy is used.

- Thick wire provides high safety compared to thin wire

| Wire Gauge | Current Rating | Circuit Breaker | uses | Cost |

| 12-Gauge | 20 Amps | 20-Amp Breaker | Kitchen outlets, heavy tools | High initial cost |

| 14-Gauge | 15 Amps | 15-Amp Breaker | Lighting, low-power devices | Low initial cost |

Conclusion

12-gauge wire is preferred; 20-amp circuits provide durable, flexible design features. It is part of outlets and lighting circuits, and it comes with different types: 12/2, 12/3, or 12/4. Its capacity, insulation, and easy current handling features provide longer and safer operation.

Frequently Asked Questions (FAQs)

How many amps can a 12 AWG wire handle?

- 12 AWG wire carries about 20 amps in short-run circuits. But if a wire is used for a continuous load, it is preferred to have a low amp rating to minimize overheating. 12 AWG wire is not applied for a 30 amp circuit, and a thick wire gauge like 10 AWG is used.

Can 12-gauge wire carry 220 volts?

- Yes, 12-gauge wire is part of a 220-volt circuit since the current is not more than 20 amps. In high loads, thick wire gauge is used.

How far can 12-gauge wire be used without voltage losses?

- We can use 12-gauge wire, about 50 to 60 feet, in 20-amp circuits before voltage losses increase. In longer distance applications, 10-gauge wire used

Is 12-gauge wire used for outdoor applications?

- Yes, we can use it with accurate insulation requirements. Using 12-gauge wire having THWN insulation for outdoor projects is preferred.

What tools are used for working with 12-gauge wire?

- For 12 AWG rated wire strippers, cutters and screwdrivers are used. For a strong connection, wire nuts are preferred for 12-gauge wire.

Can we connect 12-gauge and 14-gauge wire on the same circuit?

- No connecting of these two wires is not recommended since they are not safe. For 12-gauge wire, a complete circuit is needed. 12-gauge wire and a 20-amp breaker circuit are connected.

Why is the amp rating of 12-gauge wire so important?

- amp rating for 12 gauge wire is important for safety operations and accurate operation. If our gauges are lower, it causes overheating and fire. So a proper gauge is preferred for an accurate fuse for the protection of the circuit from overloading.

Can 12-gauge wire be part of the extension of cords manufacturing?

- 12-gauge wire is employed for extension cords, such as high-power projects like projects where power devices and outdoor devices are installed. Since it is thick, it carries a high capacity for power transmission with low losses on longer distances, making accurate working of devices without overheating.

What result if you use 12 AWG wire for a circuit that needs more than 20 amps?

- It is not good to use a 12 AWG wire circuit where more than 20 amps of current is flowing, since it results in wire overheating and affects the insulation that causes fire. For safety purposes, the best is to use the required ampacity of the circuit for electrical code support.

Are amp ratings affected by wire thickness?

- wire thickness called “wire gauge” that is needed since it affects wire amp ratings. Thick wire, like 10 AWG, carries a higher ampere compared to thin wire like 12 gauge.

What is the highest length for 12-gauge wire in a branch circuit?

- high length for a 12-gauge branch circuit based on load condition. The recommended length for a 20 amp circuit is 100 feet. More than distance, wire size affects working performance.

Is 12-gauge wire preferred for home wiring?

- 12 gauge wire is preferred for home wiring, like for circuits rated with 20 amperes or less. best for lights and outlet circuits in homes. There is a need to perform accurate installation for accurate operations.