A PCB board is a issmall chip that is used for different devices and projects. But its design and production assembly needed proper technique and planning. There are different types of assembly processes used for boards and stencils, which are also important processes for PCB manufacturing.

A stencil, also called an SMT stencil or laser stencil, is employed for the assembly of SMT components. in stencil solder paste applied on a bare board at a certain amount for the connection of SMD components on boards. The PCB stencil is considered the main part of making quality boards. Here we will cover details of the SMT stencil for PCB boards.

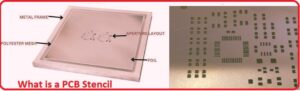

What is a PCB Stencil?

- The PCB stencil is a metallic sheet and comes with an accurate opening. It helps solder paste and adhesive flow in openings.

- The main use is to make a proper layout connection of surface-mount components.

- They aligned to the solder pad pattern on the board. It operated as a mask for applying solder paste.

- All openings are accurately on the boards for pads. Stainless steel or nickel metals are used with a thickness of 3 to 8 mils, according to the design.

- There are two PCB stencils, framed and frameless. framed stencil configured in a rigid metallic frame.

- The frameless stencil has a flexible design for manual operations.

- Some advanced stencils use laser cutting for accurate working. that has tolerances of ±0.0005 inches

SMT Stencils Types

Electroformed Stencils:

- Electroforming uses deposition of atom by atom to make a stencil. This process makes a small part of a larger surface. An electroformed stencil is a good stencil type that helps to apply solder paste and is good for complicated PCB soldering processes.

Framed Stencils

- A framed stencil is fixed on the frame permanently and used for manufacturing high-volume boards. This stencil is fixed and provides the correct position and dimension of the solder paste.

Frameless Stencils:

- As compared to a framed stencil, a frameless stencil is not connected with a frame and is used for making small boards.

Prototype Stencils:

- • A prototype stencil is employed for the manual process, with solder paste for manual application. This stencil is made according to Gerber or CAD files. The main factor of the prototype stencil is that it reduces printing errors for manual applications.

Laser-Cut Stencils

- These stencils come with apertures made with the use of a laser machine. Laser stencils make accurate designs that make them good for complicated printed circuit boards.

Features of SMT Stencil

Accuracy

- An SMT stencil helps to apply an accurate amount of solder paste that makes reliable solder joints. These accurate features avoid soldering errors such as bridging and ineffective solder.

Consistency

- Through the SMT stencil, each board comes with the same solder paste applied on the proper area. This constant is an important, high-quality, and reliable board, mostly used for high-volume manufacturing.

Efficiency:

- The use of an SMT stencil increases the solder paste application process. This high efficiency is good for larger-scale manufacturing, and low time reduces cost.

fewer errors.

- The use of a stencil reduces human errors for applications of solder paste. It minimizes errors, causes fewer errors, and increases efficiency and product reliability.

PCB stencil manufacturing process

The following steps are involved for making a PCB stencil:

Design

- First of all, the design of the stencil is made according to the PCB layout. that comes with pad sizes and defines the location of components. software used for making CAD files that define stencil design

Material Selection

- • The stencil is made with stainless steel or laser-cut polyimide materials. Stainless steel is used mostly since it has high accuracy and a durable nature, and polyimide is flexible and good for certain uses.

- The use of materials affects stencil strength and solder paste applications.

Stencil cutting

- After finalizing the design, the stencil material is cut with the use of a process like laser cutting or chemical etching. Laser cutting has high accuracy and is used for complicated designs, and chemical etching is also preferred for thick materials for getting accurate details.

Cleaning and Finishing:

- After the cutting process, the stencil faces undergo a cleaning process for removing dust or residue existing from the manufacturing process.

- This step provides that the stencil does not have any dust or contamination that affects the solder paste. finishing process, like edge smoothing, used for increasing the stencil’s performance.

Quality Control

- Proper quality control checks are performed for verification that the stencil is according to requirements and design demand. that comes with the measurement of the aperture’s dimensions and makes sure it is aligned with the board design.

Final Preparation

- After checking quality, the stencil is ready for delivery. that comes with strong packaging for avoiding damage during transportation. Instructions for accurate use are required, and proper documents are also sent to the customer.

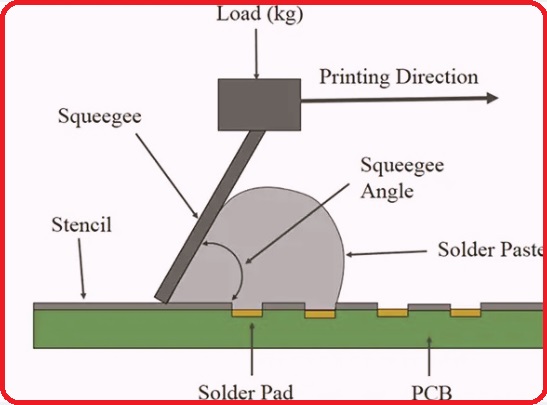

Application in PCB Assembly

- In the last step, a stencil is used for the PCB assembly process, where solder paste is applied on the PCB with stencil apertures. that provide accurate solder paste applications, which is good for getting strong solder joints during reflow soldering.

SMT stencil thickness

- Normally stencil thickness is in the range of 0.04 mm to 0.4 mm, which is good for the selection of accurate thickness according to demand, since improper solder paste causes bad quality of assembly.

- Check that accurate SMT stencil thickness provides that final assembly work according to requirements.

How to clean an SMT stencil?

- Normally, cleaning something is a difficult process and takes time, but with the use of proper methods, we can clean easily.

- Start that ensuring that you find the materials for the stencil required for the process of cleaning.

- An ultrasonic machine is preferred for cleaning SMT stencils since it has a good cleaning process and has low connection with the stencil.

- But if a connection needs to be made, use lint-free wipes moistened with mild detergent for cleaning contaminants like solder paste and flux residue.

Benefits of SMT Stencils

PCB stencils provide accuracy for the manufacturing of PCB boards. The main benefits of using stencils are as follows:

- Stencils are low cost and used for continuous repetition.

- After using, the stencil can be cleaned and also used again with the same accuracy.

- The use of an accurate stencil reduces different errors like short circuits, burred side walls, voids, etc.

- The PCB stencil helps solder paste to pass through certain apertures and makes the remaining board clean.

- The stencil also has zero errors and is used for either automated board assembly or manual processes.

- The stencil comes with time-saving features for making boards at the bulk level.

How to choose the correct stencil?

There are different factors to get the required PCB stencil, and these factors are important for the required board features.

stainless steel sheet thickness

- The accurate thickness of the stencil sheet provides the required solder paste expelled through the opening. Board thickness and apertures are the main parameters that affect solder paste applied.

- since extra solder deposits cause solder bridging. Bad solder applications make poor solder joints and affect the working of the finished PCB.

Aperture size

- Stencil opening made smaller than board pad dimensions for avoiding soldering errors like solder balls and bridges.

- When the stencil is removed from the board after soldering, solder paste moves to the board and connects to the stencil opening walls.

- For avoiding errors, board pads needed to be larger than 2/3 of the space in the stencil hole wall.

Stencil Material

- Stencil material has an effect on transferring solder paste from opening to board pads. Stainless steel is used for stencil materials. Nickel-based materials are also used for making stencils.

Stencil Alignment

- Fiducial marks added on both PCB and stencil for printing accurate solder paste on board pads. These marks provide alignment between the board and the stencil. If surface-mounted parts do not have accurate alignment, the working of the device will not be accurate.

- So alignment of the stencil is important before paste applications.

Conclusion

The use of an accurate SMT stencil comes with different factors, like stencil type, thickness, material, and size. Each parameter is important for accurate solder paste deposition and avoiding errors such as bad solder joints and bridging. Understanding certain requirements of board design and certain demands of the assembly process helps to make decisions that increase the quality of operations.

Take some time to find an accurate option and choose a good stencil for the required assembly results. For high-volume manufacturing or small-batch prototyping, the advantage of a good SMT stencil is important.