In an era of AI, IoT, and cloud-native systems, the king of the factory floor is still a product of the 1960s: the Programmable Logic Controller (PLC). PLC is reliable and used as a controller for the replacement of hard-wired relays, and its original features still define why engineers reach for them today.

In this post, we cover details for PLCs for getting dominant industrial automation in 2025 despite the rise of industrial PCs (IPCs), microcontrollers, and edge devices: their reliability, operational simplicity, deterministic real-time performance, and an enormous ecosystem of modules and support.

What is a PLC?

- PLC defines a digital controller that performs reading inputs of sensors and switches and applies user-made control logic and control output, like motors, valves, and relays, in a continuous loop.

- Practically, PLC is machine-level control, robot interlocking, sequencing, motor starting, and other related operations that require certain timing and low-maintenance service lives.

PLC reliability and professional design

PLC is made for operating in low-level to advanced-level operations. That makes it a reliable and professional module.

shop floor

- Industrial PLC is a mechanically simple design and IEC rated that operates for different conditions and humidity and manages electrical noises and vibrations. These features help for different 24/7 production environments.

Solid-state, low-maintenance operation

- Different PLCs are without fans and use solid-state memory. As compared to a standard PC, which is based on spinning hard drives or cooling fans, a PLC does not have moving parts.

“Set and forget” operation.

- After commissioning, the PLC runs for many years with some changes. For continuous process and high uptime features, these features require more than marginal computational horsepower.

- This feature makes PLC good to use where uptime and physical robustness are important.

Simplicity of programming and maintenance

The main benefit of PLCs is that they are for people who maintain machines, electricians and technicians, not for software engineers.

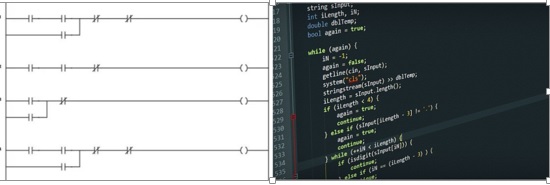

power of Ladder Logic.

- Ladder logic visual programming mirrors electrical relay diagrams, so electricians can get knowledge of programs with the use of flow and symbols. So engineers learn PLC programming faster than text-based languages.

Faster troubleshooting

- Ladder diagrams help trace failed rungs or sensors that never set, helping fast on-site fault isolation. that reduces the mean time for repairing important components for a complete line down

Lower training and staffing costs

- Since technicians maintain and update PLC logic without using a complete software development person, the net cost of using a PLC system is less than a solution built on IPC and custom software stacks.

Real-time performance and determinism

industrial control not for speed but about predictability. PLC made over a repeatable execution model that provides a strong time response

scan cycle

- A PLC can repeatedly perform a scan, get inputs, apply a program, and update outputs. Loop runs at predictable times make control features repeatable and verifiable.

Why does a general-purpose OS replace that?

- General-purpose operating systems, such as Windows and mainstream Linux distributions with many background processes, are non-deterministic; task scheduling, updates, and background jobs can introduce latency at unpredictable times.For different motion control and safety measures, operational unpredictability is unacceptable.

Safety-critical deployment

- Deterministic features are safety-related PLCs used to implement emergency stops, light curtain interlocks, and some protective functions operated with functional safety measures.

- Engineers use PLC since it can design, test, and certify safety integrity levels (SILs) or safety performance levels.

Modularity, scalability, and a vast ecosystem

PLCs are not one-off black boxes, and are modular systems that scale as changes requird.

A building-block approach

- PLC architectures start with cpu and a power supply module, which need input and output as slots in modules, digital inputs, analog outputs, communications modules, special card for motion or temperature control.

- This provides lean and future upgrades.

Cost-effective scaling

- Instead of replacing the complete control computer, operators use input or output or network for line growth. That expansion increases tool working life and minimizes capital churn.

A mature market

- The PLC market is many years old and comes with different global suppliers such as Siemens, Rockwell/Allen-Bradley, Omron, Schneider, Mitsubishi, etc., plus many third-party and specialty module vendors.

- The strong supply chain helps to find compatible, easy upgrades. The market width also includes integration design and patterns, and expertise are widely available.

- That ecosystem makes procurement and lifecycle management easy, with replacement modules, communication options, and retrofit kits in stock from multiple suppliers.

- A quick, practical resource for sourcing PLC modules and related parts is ChipsGate for industrial automation parts a B2B marketplace that lists PLC controllers, I/O modules, and accessories, which helps teams maintain legacy installations or spec new systems with confidence.

Conclusion

PLCs are continuously used since they are made for industries, maintainable, rugged, deterministic, and compatible with high chain supply and field workforce. It does not mean there is no importance of IPCs, edge controllers, or cloud platforms. Higher-level systems like SCADA, MES, analytics, and AI inference are increasingly responsible for visualization, optimization, and long-term data work, and PLCs remain the famous layer executing machine-level control. For the foreseeable future, when predictable timing and long-term reliability matter most on the factory floor, the PLC will remain the engineer’s most trusted tool.

FAQs

Why is PLC important in industrial automation?

- PLC is used for industrial automation to provide reliable working, system stability, and high performance; it reduces use of human intervention and human error.

Why is PLC preferred to microcontrollers in industries?

- Microcontrollers are low-cost. PLCs are good for industrial automation since they have good environmental tolerance, programming standards, and longer working lives.

What are the advantages of PLC in industrial automation compared to traditional relay-based control systems?

- PLC has high-accuracy features. also a complicated system. It has fewer chances for failure as compared to replay-based systems. PLCs also work well for extreme conditions. The high resistance to vibrations, temperature changes, and humidity, as compared to conventional relay systems

What are the limitations of PLC in industrial automation?

- PLC is made for certain operations and process controls and does not have easy modification features. But PLCs are lower cost than other industrial control systems, and they are high cost to buy and maintain.

Are microcontrollers replacing PLCs?

- Microcontrollers are low-cost and limited as compared to PLCs. If you are trying to find larger industrial networking, it is not good to use.