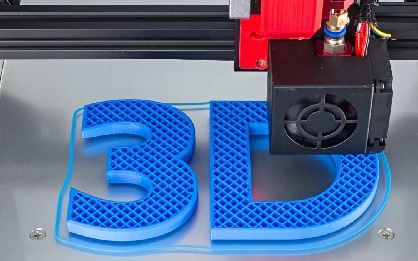

Hello, readers welcome to the new post. Today we will learn Introduction to 3D Printing. 3D printing also called additive manufacturing that helps to make three-dimensional objects through the use of CAD models or digital 3D models. It is performed through the use of different processes the deposition of material, and connection solidification through computer control.

Hello, readers welcome to the new post. Today we will learn Introduction to 3D Printing. 3D printing also called additive manufacturing that helps to make three-dimensional objects through the use of CAD models or digital 3D models. It is performed through the use of different processes the deposition of material, and connection solidification through computer control.

in the 1980s three-D printing was only used for manufacturing of functions and aesthetic prototypes and also for rapid prototyping. In 2019 accuracy, the repetition and material range of 3D printing increased and some 3D printing techniques get their importance in industrial manufacturing technology, and erm additive manufacturing was used as a synonym for 3D Printing. The main benefit of 3D printing is the ability to make complicated structures and desing that are not easy to make by hand. In this post, we will get a details overview of 3D Printing and learn how can get quality services from PCBWAY. They are dedicated 3D printing experts to meet all your industrial-level requirements 3D printing · High quality prototypes and production parts · High accuracy · Excellent service. So let’s get started

Introduction to 3D Printing By PCBWAY

- Three printing uses CAD or computer-aided desing to make three dimensions objects through layered techniques.

- From the start of the creation of graphic models objects that have to make are generally designed through the use of CAD software.

- Files are imported to a 3D printer and then the 3D printer finished the operation. There are different working principles involved for 3D printing so it has three types that are desired here

FDM or Fusion Deposition Modeling

- FDM technology is used for heating and melting filamentous hot melt material and at that instant through the use of a computer three-dimensional nozzle can be coated material on a worktable on the basis of cross-sectional profile data and create a layer when cooling is performed.

- When layer creation is finished machine table is lowered through a height of one layer thickness, then make another layer, the process is repeated till a completely solid structure is created

SLS or Selective Laser Sintering

- This technique uses powder spreading to spread a layer of powder material on the top surface of molded portion and heat is provided to a temperature less than the sintering point of the powder.

- The control system controls the laser beam on the powder layer on the basis of cross-sectional data of the layer. When scanning is completed temperature of the powder increased to the melting point, entering and bonding with the molded parts.

- When the first layer is finished workbench is lowered through the height of one layer thickness, and the spreading roller spreads a layer of uniform and dense powder on it and sinters the part of the new layer till the complete model is designed

SLA

- SLA stands for stereo Lithography apparatus, a liquid tank filled with liquid photosensitive resin, that will fastly cure through an ultraviolet laser beam released by laser. At the start of creation, the lifting workable is below the liquid level as one section is thicker.

- The laser beam focused through the lens scans the cross-sectional profile with the liquid surface on the machine command. The resin in the scanning part becomes solids to finish the processing of a layer of cross section and get a layer of plastic sheet. After that workbench is lowered through the height of one layer thickness, and then another layer is created. These layers are superimposed to make three-dimensional structures

3D printing service Advantages

Flexible Design

- 3D printing makes it possible to design and print more complex designs than traditional manufacturing processes. More traditional processes have design limitations that no longer apply to the use of 3D printing.

Rapid Prototyping

- 3D printing can produce parts in a matter of hours, speeding up the prototyping process. This allows for faster completion of each stage. Compared to prototyping, 3D printing is cheap and faster to create parts, as a part can be completed in a matter of hours, allowing each design modification to be completed much more efficiently.

Print on Request

- Print-on-demand is another advantage because, unlike traditional manufacturing processes, it doesn’t need a lot of space to store inventory. This saves space and cost as there is no need to print in bulk unless necessary.

- The 3D design files are all stored in the virtual library as they are printed using the 3D model as either a CAD or STL file, meaning they can be searched and printed when needed. Design modifications can be done at very low cost by modifying individual files without wasting obsolete inventory and investment in tools.

Strong and Lightweight Parts

- The main material used for 3D printing is plastic, although some metals can also be used for 3D printing. However, plastics offer advantages as they are lighter than their metal equivalents. This is particularly important in industries such as automotive and aerospace, where light weight is an issue and can deliver greater fuel efficiency.

Parts can also be made from bespoke materials that provide specific properties such as heat resistance, higher strength or water repellency.

High-Speed Manufacturing

- Depending on the design and complexity of the part, 3D printing can print objects in a matter of hours, much faster than pressed or machined parts. It is not only the manufacturing of the part that can offer time savings through 3D printing but also the design process can be made very fast by creating print-ready STL or CAD files.

Minimizing Waste

- Part manufacturing requires only the materials needed for the part itself, with little or no waste compared to alternative methods that are cut from large chunks of non-recyclable materials. This process not only saves resources but also reduces the cost of materials used.

Less expensive

- As a one-step manufacturing process, 3D printing saves time and therefore costs associated with using different machines for production. 3D printers can also be set up and left to continue working, meaning there is no need for an operator to be present at all times. As mentioned above, this manufacturing process can also reduce material costs because it uses only the amount of material needed for the part itself, with little or no waste. While purchasing 3D printing equipment can be expensive, you can even avoid these costs by outsourcing your project to a 3D printing service company.

Easy to Access

- 3D printers are becoming more affordable and more and more local service providers are offering outsourcing services for manufacturing jobs. This saves time and does not require expensive transport costs compared to more traditional manufacturing processes produced abroad in countries such as China.

Environmentally Friendly

- As this technology reduces the amount of material used, the process is inherently environmentally friendly. However, the environmental benefits expand when you consider factors such as improved fuel efficiency when using lightweight 3D-printed parts.

3D printing service Disadvantages

Limited Materials

- While 3D printing can create items from a variety of plastics and metals, the available selection of raw materials is not exhaustive. This is due to the fact that not all metals or plastics can be tempered enough to allow 3D printing. Additionally, many of these printables cannot be recycled and very few are food safe

Restricted Creation Size

- 3D printers currently have small print chambers that limit the size of parts that can be printed. Anything larger will need to be printed in separate sections and joined together after production. This can increase the cost and time for larger parts because the printer needs to print more parts before manual labor is used to join the parts.

Post Processing

- Although large parts require additional processing as mentioned above, most 3D printed parts need some form of cleaning to remove support material from the build and to smooth the surface to achieve the desired finish. Post-processing methods used include water blasting, sanding, chemical soaking and rinsing, air or heat drying, assembly and more. The amount of post-processing required depends on factors including the size of the part being produced, the intended application and the type of 3D printing technology used for production. So while 3D printing allows parts to be produced quickly, production speed can be slowed down by post-processing.

Large Volumes

- 3D printing is a static cost unlike more conventional techniques such as injection molding where high-volume production can be more cost-effective. While the initial investment in 3D printing may be lower than other manufacturing methods, once it scales up to high-volume production for mass production, the cost per unit will not decrease as it would with injection molding.

Part Structure

- Using 3D printing (also known as additive manufacturing), parts are made layer by layer. Although these layers stick together, this also means that they can delaminate under certain stresses or orientations. This problem is more severe when producing items using fused deposition modeling (FDM), while polyjet and multijet parts also tend to be more fragile. In certain cases, it may be better to use injection molding because it creates homogeneous parts that will not separate and break.

Design Inaccuracies

- Another potential issue with 3D printing is directly related to the type of machine or process used, with some printers having tighter tolerances, meaning the final parts may differ from the original design. This can be fixed in post-processing, but it should be taken into account that it will further increase the time and cost of production.

PCBWAY 3D printing capabilities

- PCBWAY has over 50 3D printing machines in our distribution network.

FDM

- FDM is a technology used for 3D printing famous for high-speed operation, accuracy, and competitive prices. FDM machines accurately extrude melted plastic filament to products

Vacuum Casting

- Vacuum casting is a copying technique used to produce small series of functional plastic parts. Using two-component polyurethanes and silicone molds, Vacuum Casting is known for its rapid production of high-quality prototypes or final products.

SLM

- Additive manufacturing of metal parts is set to revolutionize how many things are made. Selective laser melting or SLM is a type of metal additive manufacturing or 3D printing. Often the terms SLM and direct metal laser sintering (DMLS) are used interchangeably.

DLP

- Digital Light Processing is a 3D printing process that uses a projector to cure photopolymer resin. Very similar to SLA where the only difference is that instead of a UV laser a safe light (light bulb) is used to cure the photopolymer resin.

SLA

- Stereolithography (SLA) is an industrial 3D printing process used to create concept models, cosmetic prototypes and complex parts with complex geometries in as little as 1 day.

Tolerances for 3D printing Capabilities

| Feature | Tolerance |

|---|---|

| Our lead times | From 2 |

| Maximum build size | 2100mm*700mm*800mm |

| Dimensional accuracy | SLA: L<100mm,±0.2mm. L>100mm,±0.2%*L(mm) DLP: L<100mm,±0.1mm. L>100mm,±0.1%*L(mm) SLS: L<100mm,±0.25mm. 100<L<200mm,±0.3mm. 200<L<500mm,±0.5mm. L>500mm,±0.1%*L(mm) MJF: L<100mm,±0.25mm. L>100mm,±0.25%*L(mm) SLM: L<100mm,±0.3mm. L>100mm,±0.3%*L(mm) FDM: L<100mm,±0.2mm. L>100mm,±0.2%*L(mm) |

Best 3D Printing Material Selection

SLA (Stereolithography)

SLS (Selective laser sintering)

DLP (Digital Light Processing)

MJF (Multi Jet Fusion)

SAF (Selective Absorption Fusion)

FDM (Fused deposition modeling)

SLM (Selective Laser Melting)

That is all about the 3D Printing all details has explained. Also not to forget the use of PCBWAY services, Thansk for reading have nice day.

Aw, it was so kind of you to showcase how affordable and eco-friendly 3D printing is. My wife wishes to give a personalized keychain to her secretary who’ll transition to another workplace next month. I’m so going to recommend this article to her so she can come up with a nice product with the help of a professional in the end.

Thank you for all of your help. Your carrier became superb and really FAST. Many thank you for you type and green carrier. I even have already and could clearly hold to advise your offerings to others withinside the future.