Hello readers welcome to new post. Here we will discuss Different Types of PCB. Although the term “PCB” refers to printed circuit boards, a more specific term for this type of circuit board would be Printed Circuit (PC) Board. This is a circuit board which is in the form of a PCB. A PCB is basically an electronic board with a lot of different elements, such as resistors, capacitors, etc. There are different types of PCBs by the manufacturers or by their own design. The most common types of PC boards are surface mount and through hole (SMT). SMT means that the resistors and capacitors are always soldered to the pads on the PCB. The other type of PC boards is through-hole (T-Hole). In this type of T-Hole you need to permanently affix your components onto the board using epoxy or other adhesive material.

There are some minor differences between these two types of boards in terms of soldering procedures used for mounting them and also in their dimensions but it doesn’t really matter since they both have an entirely different function as well as circuits.

- PCB is a highly durable circuit board, made of glass fiber and epoxy resin. It is used for the manufacturing of electronics and electrical devices.

- It has become a very important part of all electronic device, including computers, handheld mobile devices, digital cameras, refrigerators, air conditioners and many more.

- It also serves as a platform for the connection of other components such as capacitors, resistors and inductors. Also it can be used for a transfer gate in the FETs. PCBs are also used in industrial machines that require precision mechanical components such as gears or shafts since they are robust, reliable and affordable to manufacture.

- We need to know PCB to get the right quality products at competitive price.

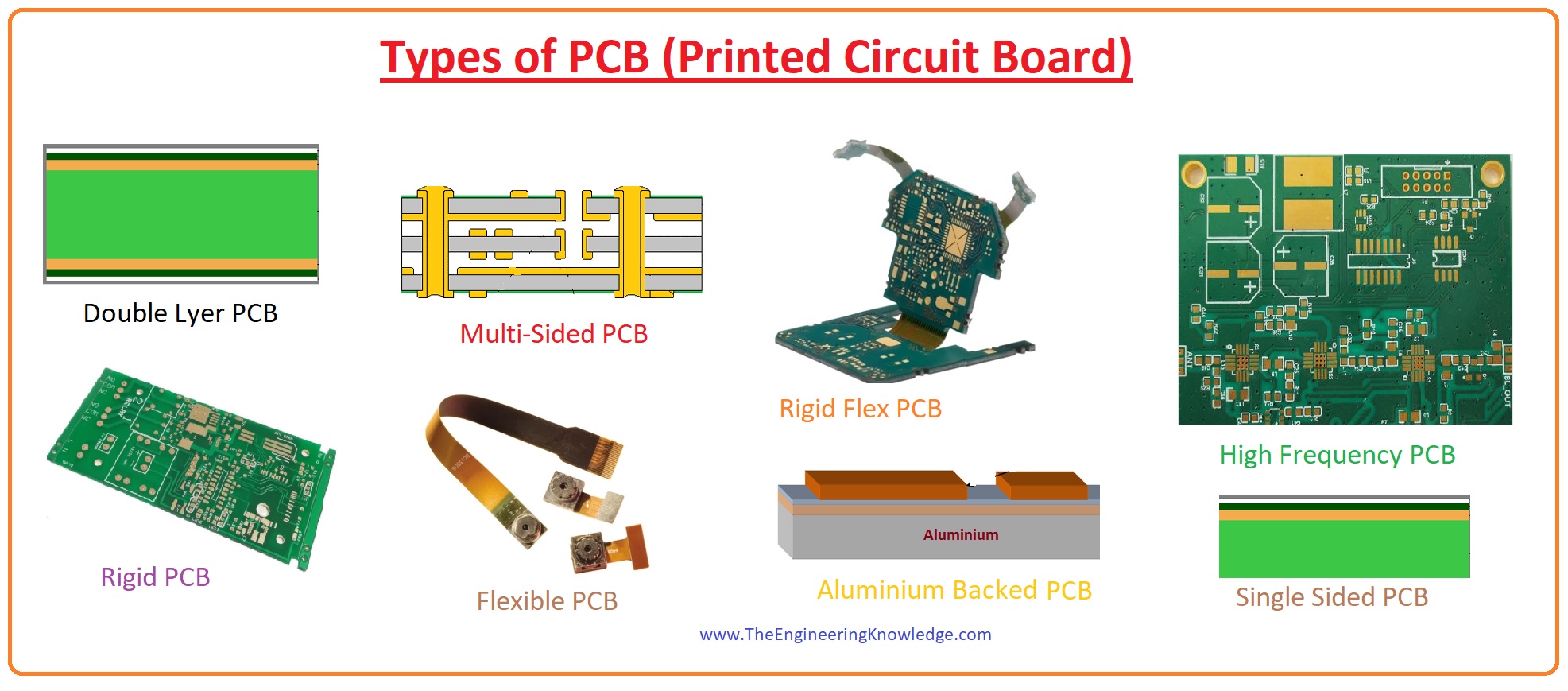

- However we need to know more details about it before purchasing it. So we have decided to write this article so that you can have an idea about what types of PCB you can use in your product or project. We have different types of PCB:

1) Printed Circuit Board (PCB)

2) Service Marking Board (SMD&P)

3) Mixed Mode Board (MMBS)

4) Thin Film Circuit Boards (TFCC)

5) Micro-Electrical-Machining (MEMC)

How is PCB made?

- The first pcb was invented by the German engineer, Gottfried Wilhelm Leibniz (1646-1716). He was the head of the German Mathematics Office for over twenty years and is considered to be one of the main contributors in the development and development of modern mathematics. His work on pcb is just one of these contributions. In his time, pcb was a very new technology. It was also very expensive. That’s why he had a hard time introducing it in his own country, England. But there were people who found out about this technology and started to use it for their own purposes. From that point on, the pcb industry started to grow rapidly and its popularity increased quickly.

- Today almost all electronic devices are made using pcb in some form or another: computers, cars, appliances etc., but why? When did it become so popular? The reason is simple: thanks to its versatility and durability, it allows you to manufacture a whole lot more than just circuit boards! PCB is also very easy to work with – as long as you know what you’re doing!

- The process of making a PCB starts with drawing a plan that shows how wires will be connected (transistors etc.). This drawing must be precise enough so that when printed onto the board at actual manufacturing time they fit perfectly in place. Once this is done, engineers have to make sure every single wire from one part of the circuit board leads into another part exactly where it should be (for example: transistor leads into capacitor).

- Then they need to wire up all other parts of the circuit board so everything works perfectly together (for example: capacitor leads into transistors). There are many ways for wiring up these parts; some are quite precise and precise others can take hours or even days (I used to do this myself!).

- Finally after all parts are wired up we need to put them together – something called soldering! This step requires precision because if solder melts too thin or too thick it can cause trouble later on during testing or assembly – something that can cause more problems than good!

Engineering requirements and constraints in PCB Manufacturing

- There are many PCB manufacturers currently operating in the field and providing various PCB related services. But the most famous and reliable PCB manufacturer I associate with and use their services is PCBWAY. Each PCB supplier has its own features and products but the key thing that makes PCBWAY stand out is its high quality products with affordable prices and product delivery to the customer in a timely manner.

- PCBWAY is a Chinese-based PCB manufacturer that provides various types of PCB and PCB services such as solid PCB, single layer PCB, double layer, PCB, multilayer PCB, etc.

- They Produce Reliable PCBs for demanding customers. Get your quote in seconds, PCBs delivered as quickly as 1 day

- PCBWay is a PCB manufacturer and PCB compiler. Shenzhen has for decades been a global center for electronics R&D and manufacturing. By skipping all the middle companies, we succeed in delivering savings and bring complete satisfaction of PCB / PCBA purchasing experience to our valued customers. That’s why 100% of our old customers come to us to get their future orders.

1. Printed circuit board (PCB) – is a special construction material used for manufacturing electronic devices and electrical components. It is made from the epoxy resin and glass fiber.

2. Printed circuit board assembly (PCBA) – is the set of components used for assembling devices into functional modules such as PCBs, printed circuit boards, and passive components.

3. Printed circuit board connector assembly (PCCA) – is a kind of mechanical connector with which electrical components are assembled into multi-layer printed circuit boards or PCBs.

4. Printed circuit board fastener assembly (PFCSA) – is an assembly of connectors and fasteners used in printed circuit boards to assemble multilayer boards into assemblies that can easily be installed on the printed circuit board and remain stable under pressure or vibration while being powered during operation of electronic circuits such as those found in computer circuitry, to protect the electronic circuits from damage due to shocks or vibrations, etc., etc., etc..

5. PCB housing assembly (PHSA) – may also be referred to as pcb housing; it consists of all the components associated with a single PCB that form a complete enclosure for one or more individual printed circuit boards which are either held together by mechanical fasteners or mechanically attached together by adhesive bonding methods such as glue bond or glue-bonding techniques such as self-adhesive tape, laminate bonding techniques, or thermal bonding techniques such as thermal bonding techniques; these elements are typically mounted on a baseboard that accepts all components required for mounting and assembly onto one printed circuit board but does not allow access to any other component than those provided by this baseboard’s mating surface areas having mating surfaces not covered by any other component(s).

- The components such as chips and integrated circuits are fabricated on the printed circuit boards or PCBs. These boards are often called printed circuit boards or PICs because they have pins (like pins on a chip) on them that connect those chips together with wires or cables. These boards are usually manufactured by non-electronic manufacturing companies to be used in various electronic products like computers, cell phones and other electronic devices.

There are many different types of PICs but we will be focusing on just one type namely integrated circuit produced using these boards which is mainly used for making microprocessors (micro computers). This includes CPU (Central Processing Unit), FPGA (Field Programmable Gate Array), ASIC (Application Specific IC), etc… If you want to learn more about this topic we recommend reading our previous post titled “Different Types Of Printed Circuit Boards”. Suffice to say here that anything connected to any other thing is called an integrated circuit because it can only be manufactured when all its parts have been put together properly. So if you want to learn more about different types of printed circuit boards please read our previous post titled “Different Types Of Printed Circuit Boards” where we explained about TAB-Board, SMT-Board, etc… The advantage of using these printed circuits rather than just connecting pieces of metal is that they allow us to have a smaller size for each component and thus lower manufacturing costs. We can also choose between copper plating and solder plating over it so that we can produce machines with higher density production lines because these require less metal than those without copper plating or without solder plating respectively.

We can choose among three different packaging materials for our electronics products: PET (Polyethylene terephthalate), PET-LDPE (Polyethylene terephthalate – Low Density Polyethelyne) and HDPE (High Density Polyethelyne). We will discuss what’s wrong with each

Processes for making the PCBs

- Some types of pcb are used in the electronic and electrical industry. Sometimes, it is called circuit board. These are found on the boards of different electronic devices such as computers, smartphones, televisions and other electronic appliances, solar panels and most importantly an electric vehicle. It is made by the glass fibers of some fibrous material, which is normally epoxy resin (sometimes called PCB epoxy) or a glass fiber composite (GFEC). In terms of their structure, these are considered to be similar to a regular circuit board in terms of its features.

- Today PCB play a very important role in the electronic and electrical industries. Almost each and every circuitry of the device consists of PCB (Printed Circuit Board), which stands for Printed Circuit Board (circuit board). This circuit board is manufactured by the glass-fiber epoxy of some other related materials. At this circuitry process we have different types of pcb that are found on the boards of different electronic devices such as computers, smartphones, televisions and other electronic appliances – solar panels etc. We do not need to go into details here however we can definitely say that they all have something in common – they all were made through pcb manufacturing process.

Designing a PCB for high performance and reliability

The word “design” doesn’t have any meaning. Just like the word “elevator” doesn’t mean a car, just like a computer doesn’t mean an operating system, just like an air conditioner doesn’t mean a heating element. The way you design a PCB is different for each type of product.

Different types of pcb include:

– FETs (Field Effect Transistors) and MOSFETs

– Diodes and N-channel FETs (Notch-shaped transistors)

– Pins, Inductors and Capacitors

– Resistors, Filters, Capacitor Networks, etc.

- The differences between each type have to do with physics and manufacturing process. At some point in time every manufacturer decides to make the product according to their own vision of what the product should look like – not only in terms of size or shape but also in terms of its performance characteristics and reliability.

- For example if you are building semiconductors or electronic components then you will have to come up with a different way of manufacturing them. In this regard it can be said that there are two types of pcb’s: the ones that require high quality manufacturing process (such as VLSI), which are costly; and those that can be produced at very low cost (since they are made by simple PCB clamping electrodes). PCB’s being used for consumer electronics is one such case where you would find both types on the market – devices with higher performance results from using cheap devices with lower performance results from using expensive devices. In other words, cheap devices are more reliable than expensive ones even if they do not perform better than expensive ones. So what makes one type better than other? This has to do with how much power is required for them to perform at their best level.

- A small difference in power requirement means that one type might perform well while the other does not perform well at all when used together in an electronic device or circuit generating circuit boards made by these two types cannot be compared to each other since they have completely different power requirements so far as cost is concerned but still they can be compared in terms of overall efficiency since they use similar components together as opposed to just being placed next to each other without any connection between them because otherwise efficiency would vary from device to device due to varying capacitor values etc which

Conclusion

Well, I think the topic of different types of PCB is beautiful. We have the different types of connectors, we have the different types of PCB, we have the different type of sockets. There are also different things that you can do with PCB. The best way to describe it is like a single piece of wood. Each piece of wood has its own unique features and characteristics and can be used in a variety of ways. You can use it for pretty much anything and whenever you need to use it as a single piece of wood. It’s good to have this knowledge in your mind before you work on your project. There are some tools which let you easily change out certain parts on your project and you can even modify them to fit with other parts in your project so that they are easy to carry around with you everywhere (like our connector sets).

That said, when doing repairs on circuits or other projects, be sure to take into consideration that there are many differences between different channels (some connectors may be compatible with several types; some may not).

When working with electronics-related materials, one thing that needs to be considered is their properties: how will they react when subject to heat? Will they swell or expand? Will they melt or contract? How well will currents pass through them? Different materials have these properties and their qualities can affect what kind of projects you’ll work on at the same time. For example, lead-free soldering irons require a bit more care than those that aren’t lead-free because lead interferes with soldering fluxes used in solder joints (which is why many people prefer lead-free solders). When handling electronics, keep this information in mind:

• Heat – heat stress is just as important as electrical stress – do not leave a device in place for long periods without removing it from its housing or exposing it to extreme temperatures!

• Swelling/Expansion – solder joints swell or expand over time depending on how much heat is applied to them (and humidity!). In general, solder joints should not swell if exposed only for 2 minutes at room temperature; however this depends greatly on what the material is made from (e.g., copper) and whether it was well tinned before being soldered together!

• Conditions – if there is moisture present anywhere else on the circuit board then moisture may cause corrosion problems as well!