Hi friends I hope you all are doing great. In this post, we will have a detailed look at Difference between Rigid PCB and Flex PCB by PCBWAY. PCB is the most commonly used electronic project board over which different types of electronic projects are designed. The strength working and durability of your project depends on the strength and quality of the PCB used for project creation. There are numerous PCB suppliers are working in this world but the most famous PCB supplier which i recommend and also personally using its services is PCBWAY. It provides different services related to PCB and its different parameters such as PCBA.

Hi friends I hope you all are doing great. In this post, we will have a detailed look at Difference between Rigid PCB and Flex PCB by PCBWAY. PCB is the most commonly used electronic project board over which different types of electronic projects are designed. The strength working and durability of your project depends on the strength and quality of the PCB used for project creation. There are numerous PCB suppliers are working in this world but the most famous PCB supplier which i recommend and also personally using its services is PCBWAY. It provides different services related to PCB and its different parameters such as PCBA.

There are numerous types of PCB according to their construction and uses such as single-layer PCB, double-layer PCB, and multiple-layer PCB. The two main commonly used types that we are going to discuss is rigid and flex PCB. Both of these PCB types can also get from PCBWAY at a reasonable price. So let’s get started with Difference between Rigid PCB and Flex PCB by PCBWAY.

Rigid PCB vs Flex PCB

- During the construction and design of rigid PCB board, there are some rules should be followed that are least size of the hole, lease space and trace dia, the distance between board edges should be less with that copper, and complete designing thickness should be under control

- There are numerous steps during the construction of these two PCBs are similar.

- Such as the drilling and plating process of holes imaging and creation etching of copper traces outlines and heating purpose of the board to eliminate water vapor from the board.

- During this point in the procedure of construction, a rigid PCB board flowed the solder mask station and flex circuitry went to the coverly station.

IPC Standards followed by Rigid and Flexible PCBs

- Here the detail of IPC standard for rigid and flex PCB is shown below.

- For generic standards at the printed board, designing IPC-2221A is used.

- For sectional designing IPC-2223 standard is followed.

- For features of base substance in rigid and multilayer, PCB board IPC-4101 standard is used.

- For flex base dielectric in flex circuitry, IPC 4202 is used.

- In the creation of flexible printed circuits IPC-4204 flexible metal called dielectric is used.

Wire Current carrying capacity

- As there is a difference between the heat capacity of rigid and flexible PCB it is compulsory to offer enough width of the wire.

- There is a large amount of current from some wires when they are placed close to each other for this there should be additional spacing or a large wire of width used.

Shape

- It does not matter in the situation certain rectangular size should be used since it can provide a good quality base close.

- Close to the edge of freedom must permit enough margin according to the substrate.

- In an aspect of shape, a round angle should be preferred while pointed angles can cause a tear panel.

- There is a need of a reduction in the small conductor width and space.

Flexibility

- It is a basic principle that the bending radius must be created at a larger strength. The usage of small laminate such as one twenty-five micrometer copper foil in place of wire and larger it can bear further instruction for high cycle bending of bending cycles.

Pads

- About the pad, there is a variation from flex substance to rigid substance. This part of the conductive substance can easily be fractured.

- So pad must be used in this part that is prone to bending. The physical dimension of the pad must be like a teardrop.

Where use rigid PCB and where use flexible PCB

- The price of a Rigid PCB is more costly than the flex PCB. If you take price under consideration then you must use flex PCB in your projects as it is less expensive.

- Flex boards can eliminate the requirement of elements such as wire harnesses, connectors, and some other circuit parts.

- As result, it reduces the construction and labor expensive price of materials also reduces.

- There are numerous electronic modules constructed with rigid PCB in place od flex PCB such as laptop and desktop computers, keyboards, SSD, TVs, toys, and some other electronic devices.

- While in some high-performance modules like GPS, smartphones tablets cameras, and wearables flex PCB is used,

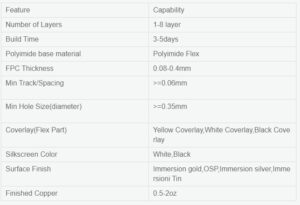

PCBWay flexible PCB manufacturing capabilities

- The features provided by the PCBWAY for flexible PCB are described here int he below figure.

That is detailed post if you have any further queries ask in the comments. Thanks for reading.