Hello, readers welcome to the new post. In this post will discuss Construction of Multilayer PCB. PCB is a very important and main part of electronic projects and instruments and no device can be created without this module. Over the board, all components of any electronic project and device is placed and linked in the circuit. There are traces of copper is drawn over which circuits and symbols of the different components are assembled to make the project.

Hello, readers welcome to the new post. In this post will discuss Construction of Multilayer PCB. PCB is a very important and main part of electronic projects and instruments and no device can be created without this module. Over the board, all components of any electronic project and device is placed and linked in the circuit. There are traces of copper is drawn over which circuits and symbols of the different components are assembled to make the project.

There are many PCB providers are functioning in this world. Here I want to a declaration that the greatest and consistent PCB provider that comes with altered kinds of PCB boards such as single-sided, double-sided rigid PCB. with that PCB they also offered multilayer PCBs with reasonable charges can easily get for anyone. This greatest PCB provider is PCBWAY. PCBWAY comes with these PCB boards and offers all desirable necessities for a single platform.

PCBWay, offered standard PCB, can aid to make 2-14 layers, even more layers for selecting advanced PCB. You can get HDI for 4-layer or more. Through-hole board PCB is offered in advanced PCB with IPC 6012 class 2. Layer advanced up to thirty layers can get. Standard PCB in material FR-4, Aluminum, and rogers can get. In standard PCB you can get solder masks in colors Pink gray orange and transparent solder masks with Black FR4 also accessible. PCBWay offers all wanted to take electronics projects from start to finish, although more than seventy on-staff specialists guarantee zero-defect quality declaration and appropriate delivery. The procedure of making such goods usually originates with PCB prototyping. As one of their most widespread facilities, there is practically no boundary to the size, shape, and complication of PCBs the company can make, letting you to tweak board considerations to comprise diverse base ingredients, widths and quantity of layers, silkscreen colors, and solder masks, surface finishes, and etc

In this post, we will have a detailed construction of multilayer PCB, features, advantages, and other parameters. SO let get started.

What is Multilayer PCB

- The type of PCB that is created with more than two layers is called multilayer PCB and comes with three layers having the ability to conduct current and are linked with each other.

- The layers quantity in multilayer PCB should be four-six, eight and so on.

- The design of this PCB board is somewhat complicated and its layers configurations at upper and lower sides is similar to double-sided PCB with a difference that having stakes.

- All layers on this board are assembled such that make the single multilayer PCB board and are linked through holes of copper plated.

- The use of multilayer PCB increases due to variation in the different technology in industrial machines and devices.

- WIth the passages of time there is advancement is introducing in the electronic and needing more complicated boards.

- So in single and double layer usage in different projects were crating some problem such as noise crosstalk stray capacitance and do not have the ability to handle larges projects of engineers considered to introduce the multilayer PCB board.

- To fulfill the users and project demand there is different dimensions and sizes fo of boards are created and have 4 to 12 layers.

- Numbers of layers are created in even numbers and odd numbers can create different problems such as warping.

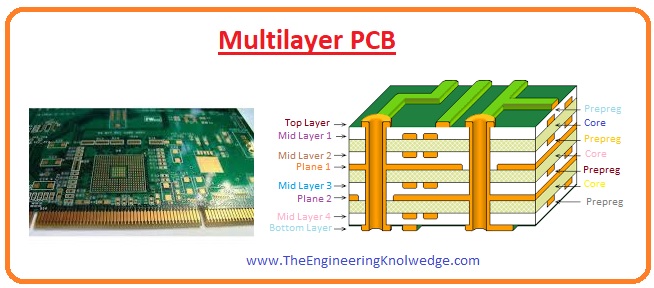

Construction of Multilayer PCB

- There are certain types of processes and care is needed to make this complicated circuit board to avoid the circuit mixing interlinking of connection.

- To make the PCB there is a special arrangement of machines and instruments used.

- Mian steps for the construction of multilayers PCB are explained here.

- First of all design of board is created through use of different types of software such as proteus, Eagle etc.

- After that internal layer, core is created and laminate of the required dimension are crated with the sue fo copper sheet.

- Now lamination is done through internal layer occurs prepeg foil and sheets of copper.

- In this stage staking of layers is done in different steps such as the lower layer through the copper sheet, then preperg sheets, internal layers, then prepeg here and at last copper sheet placed at the upper side.

- At last pressure is applied through the use of a hydraulic press machine. for removing the air there must be a vacuum created.

Factor Affecting Manufacturing Multilayer PCBs

- There is some point you must keep in mind during multilayer PCB construction. Such as power integration and signal integration.

- Current can flow through copper traces but at limited value mean offered some value of resistance to larger current.

- There is the usage of control impedance traces. To bear the large value of temperatures the thickness of coppers in traces should be large.

- To bear the width of the temperature of traces should change according to configuration.

- there is no vertical traces to avoid the phenomenon of electromagnetic induction.

Multilayer PCB Advantages

- The main advantages of multilayers PCB are listed here with the details.

- Its main benefit is that exists and is created in a small size then other boards. Due to its small size it is used in laptops, mobile phones tablets.

- Its design is less weight and used in different types of projects due to less weight.

- It also offered features of high quality over the other boards and is reliable for different projects.

- Its durable and long life operation makes it effective for different projects. Has the ability to work in high-temperature and pressure conditions.

- There are features if high density offered by the board.

- It also has features to work as one module without the combination fo other boards

Multilayer PCB Disadvantages

- Mian disadvantages of multilayer PCB are explained here.

- Due to the difficult design and requirement of special equipment, its cost is larger than other boards.

- Its construction is complicated than other boards and need careful techniques of making this board.

- As there is some companies that created this board so its availability is less.

- Due to complicated design there is need of a skilled person to make it.

Comparison between SIngle Layer and Multilayer PCB

- Single-layer PCB is less dense while multilayer PCB has high density and high density make multilayer PCB effective for different projects.

- The size of multilayer PCB is less than single layer PCB and these features make it useful in small size devices such as mobile watches tablets. multilayer PCBs are to be used in smaller devices, while high-capacity single layer PCBs must be installed into larger products.

- Wight is multilayer PCB is less than the single-layer PCB.

Multilayer PCB Applications

- There are different uses of this board according to design and structure.

- Its small size and less weight make it useful in the construction of smartwatches.

- It is used in laptops, mobile tablets, etc.

- It is used in telecom such as in devices sued for signal transmission, satellite.

- In industries, different devices are created with use of this board.

- Medical instruments are created with this board.

- In the military, there is different instruments are created with this board.

That is all about the Construction of Multilayer PCB. I have explained each and every parameter related to this tutorial. i hope now you have a detailed understanding of this board. For further query ask in comment. Thanks for reading have a good day.