The blower resistor main part of the car’s heating and cooling system, which regulates fan speed for blowing air in vents and controls airflow. If the blower motor resistor is not working, it can completely affect the fan’s performance, and it will work at different speeds, and also, air will not come from the vents.

In this post, we will cover the detailed features of the blower motor resistor and its importance for solving HVAC faults of vehicles. So let’s get started.

What is a Blower Motor Resistor?

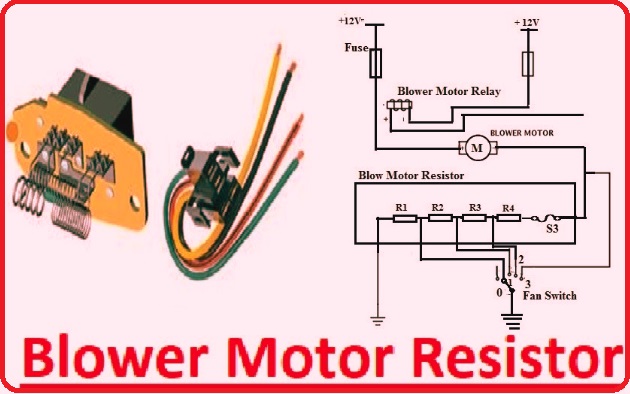

- The blower motor resistor is the main part of the HVAC system of the vehicle. It is a rectangle-shaped design that comes with different variable resistors.

- The main function of this module is to control blower motor speed, which also controls the fan speed of the HVAC system.

- It is connected close to the engine or, in some vehicles, below the dashboard towards the passenger side with the blower motor.

- Its main function is to handle the heat generated by the blower motor airflow and also the resistance.

- Its connection with the HVAC system of vehicles is in a series circuit combination.

- This resistor gives different resistance for controlling the voltage given to the motor.

- If resistance is high, fan speed becomes low, and voltage also reduces, the motor stops.

- For high speed of motor resistance, a low or high voltage is given to the motor. With these speed changes, we control speed at different airflows.

Components of the blower motor resistor

Different parts of the blower motor resistor peform different functions.

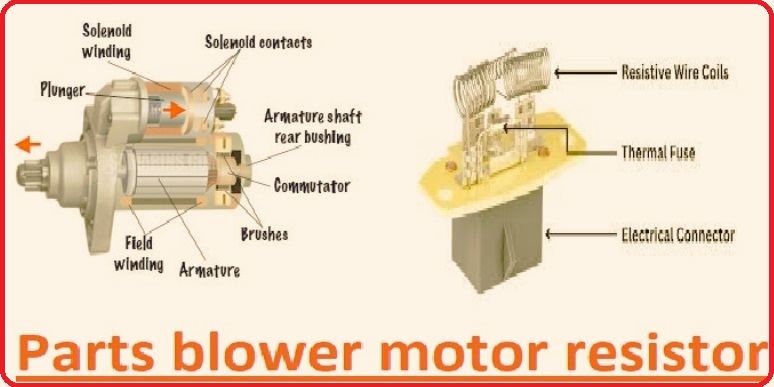

Base

- It is made of ceramic and manages heat resistance, and provides a level of insulation.

Coiled resistors

- It is a loop made with a Nichrome wire mixture, and this resistor controls voltage through conversion into heat.

Electrical connectors

- It provides good conductivity for resistor circuits, motors, and control switches.

Housing:

- It saves the resistor from dust and moisture in the HVAC duct.

Blower Motor Resistor Working

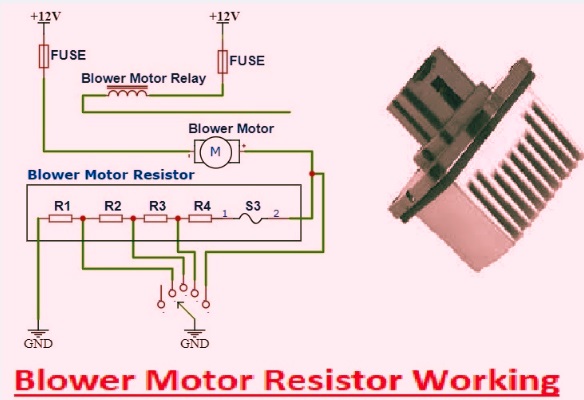

- The blower motor resistor is used for the blower fan, controlling the speed of the blower fan by changing electrical resistance. A resistor connected to the fan switch that takes part in varying the airflow of the speed of the car.

- Based on structure, it is done mechanically through knob rotation or electrically with a digital control system.

- In old models of vehicles, resistors vary with power regulation moving toward the blower motor.

- High resistance causes low fan speeds that minimize the voltage given to the motor.

- When high speed occurs, low resistance exists, causing high power flow and the fan to spin fast. This method is also applied in modern vehicles, where a solid-state module is used compared to a conventional resistor for controlling the blower motor speed.

- The blower motor resistor is connected in a series combination with the fan motor and the ground terminal. Based on the speed setting, it comes with different configurations. Each speed factor comes with a certain resistor connection that controls the flow of current to the motor.

- If high fan speed is selected, the resistor is bypassed, and the blower motor gets high power. As a result, the fan’s moving speed becomes high. In reverse, the resistor voltage reduces, as does fan speed.

- For a low resistor value, the blower motor operates at a constant speed or stops working completely.

Faulty Blower Motor Resistor Symptoms

Different signs indicate the blower motor resistoris faulty and not working well.

Fan speeds are not constant.

- Fans normally work at a constant speed, so if their speed varies, it causes faults.

Fan on One Speed

- If the fan speed is not varying, it means there is a stuck sign of a failing blower motor resistor. It is a result of the resistor controlling the current moving into the fan motor, setting the speed. Normally, a fan operates on a single resistor when it is damaged.

- Replace the damaged resistor solve that error.

No Airflow from Vents

- No airflow occurs when the resistor is broken, which results in no airflow in vents, and also when other components of the HVAC are working.

Special odor

- A faulty resistor also causes overheating; as a result, a burning smell can be observed in the dashboard area.

Irregular function

- The fan works irregularly, like sometimes it works, and at other times it instantly stops working.

electrical faults

- Some electrical faults, like dashboard flashing, also indicate faults of fan speed.

Control System Malfunction

- A faulty resistor also affects the complete control system of an automated car.

Noise

- A faulty resistor causes different noises, like clicking, when we change the fan speed.

Warning Lights

- damaged resistor resulting in dashboard warning light on for a different vehicle

Fuel Efficiency

- For moving at high speed, a fan stuck due to high load causes low fuel efficiency.

Blower Motor Resistor vs. Blower Control Module

| Feature | Blower Motor Resistor | Blower Control Module |

| Working | control blower motor speed through changing the resistance of the circuit | it controls blower motor speed with the help of transistors or microcontrollers through an electronic circuit. |

| Technique | it works with a fixed or variable resistor that minimizes the voltage given to the blower motor. | it operated with solid-state electronics, varied speed control |

| Speed Control | 3 to 5 levels | operate with infinitely variable speed control for uniform working |

| Uses | It is commonly used in vehicles where a manual havac system works. | vehicles with automatic climate control systems uses this system |

| parts | Its structure comes with resistive coils and a thermal fuse. | made with sensors, MOSFETs, , and microchips. |

| Durable features | Affected with overheating and damage due to high current load. | Durable but can affect wth moisture or electronic faults. |

| Replacement Cost | Low-cost parts are easy to replace. | High cost and needed diagnostic tools for changing |

| Failure sign | Blowers operate with certain speeds | Blower speed varies or not work for automatic controls. |

Blower Motor Resistor Testing Method

There are different steps involved for testing the blower motor resistor that help it to operate well.

- First of all, take safety measures for this: disconnect the vehicle battery before starting the inspection to avoid short circuits or damage.

- Now check the car manual for finding the location of the blower that is normally in the engine compartment, or below the dashboard on the passenger side.

- Now perform a physical inspection and find a burning or damage sign; with that, also inspect corrosion on the connector.

- Now disconnect the resistor from the circuit with note connection points.

- Set the multimeter setting for resistance measuring or ohm setting. for car set range 0–20 ohm.

- Now connect the pins of the meter with the resistor terminal combinations and get different resistances for each connection.

- Now make a comparison of the resistance value taken with the meter to the car’s manual readings.

- Check infinite resistance, so an OL reading of the terminals means an open circuit, and the resistor is not working.

- Temperature also affects resistance value, so perform the test in operating temperature conditions.

- Test resistor connectors to make sure that they are working well and do not have faults.

- Perform voltage drop tests over the resistor when the blower is working at different speeds.

- noted all measured results and got service from a technician if a fault exists

Causes of Blower Motor Resistor Failure

High temperature

- The main cause of blower motor resistor failure is overheating due to high temperature. Due to the current flow, the blower motor resistor coil causes high heat. This high heat causes damage; for managing heat, a thermal fuse is used. If not controlled, overheating causes damage to the resistor.

Longer time use

- With the passage of time, blower motor resistors get damaged and face wear and tear. The regular change in fan speed and temperature, and longer use cause degradation.

Corrosion

- • The vehicle faces changes in temperature and moisture. With time, that corrodes the blower motor resistor’s electrical connectors and pins.

- Corrosion affects the conductivity and also the working of the resistor.

High Loads

- When we use the HVAC system regularly with a high fan speed, it causes a high load on the blower motor resistor.

- that causes wear on the resistor and, as a result, damage

Dust

- Dust and dirt accumulate on the blower motor resistor. that affect airflow and ventilation, cause overheating, and get damaged.

voltage surges

- If power varies, it causes voltage surges and applies high stress on the blower motor resistor. If abrupt voltage increases cause high current flow, they can damage the resistor and other connected parts.

Replacement of Blower Motor Resistor

locate resistor

- First of all, find the resistor location, which normally exists close to the blower motor or below the dashboard, and some vehicles have it in the engine bay.

- If facing difficulty locating, check the vehicle manual.

Disconnect Blower Motor Resistor

- After finding the resistor, disconnect it from the vehicle. For this step, first of all, remove its housing. that can have a pigtail connector that connects with the air conditioner system.

- Through removing screws, separate the resistor

Remove wires.

- Now disconnect the connected wires with cutters for disconnection. But before removing wire connections, note them.

Connect the new blower resistor.

- Now you are ready for the connection of the new resistor. Before that, use dielectric grease over the housing. that prevent moisture and that help when driving on wet roads.

- Connect the new resistor at that position and screw it. Connect wires at a real connection.

Replacement Cost of Blower Motor Resistor

- Based on the vehicle, the replacement cost of the blower motor resistor is in the range of 20 to 80 dollars. It is a cost-effective replacement component of the HVAC system.

- But based on location and service center, replacement costs can differ.

- Normally, the overall budget for replacement of the blower motor resistor is in the range of 50 to 300 dollars for labor and parts.

- But you can save labor costs by replacing it at home.

How to Reset Blower Motor Resistor?

- Different methods are used for resetting the blower motor resistor.

Disconnect Batteries:

- First of all, set the car in off-off conditions. For this, check the battery location in the car; it is in the engine compartment and also lies beneath the seat.

- Now remove the battery negative pin, and wait for some time. So with draining the car’s electrical system, any electrical fault will be removed.

- In the last step, make the connection of the battery terminal and secure it.

Disconnect Fuse:

- Now find the fuse box, which is in the engine compartment or below the dashboard. Find the blower motor and fuse. For detection, the fuse can check the vehicle manual.

- Disconnect the fuse for some time and then connect it again. that blow motor resistor becomes reset.

Control Module resetting

- HVAC systems in some somevehicles operated with electronic modules. that can reset when the battery disconnects from the vehicle.

- through pressing and holding the HVAC control button for resetting.

Blower Motor Resistor Inspection Method

- For this, first locate the resistor that is below the dashboard or closest to the glove box. Remove it through a disconnected connection.

- Check that the resistor does not have any damage or corrosion. If it exists, clean it with a cleaner and connect again.

System setting

- Start ignition after performing the above settings, without starting the engine. Set the fan to high speed and run it for some time.

- Check fan speed during setting to high speed. This method sets the system and overall working.

Reset Computer

- Connect the battery and start the engine, and run in idle conditions. Do not touch the climate control when the engine is idle. since the computer automatically sets the HVAC system.

Diagnostic Reset service center

- If resetting is still needed, take the vehicle to a repair center; they will perform the resetting and remove the error codes.

Conclusion

The blower motor resistor is the main component that is used for controlling the speed of the car fan. If the resistor is not working, it affects the working of the fan; if it is working, the speed does not vary, and stops airflow in the vents. So different tests are performed on the faulty resistor, and then it is replaced with a new resistor for the working of the heating and cooling system.

FAQ

Define blower motor resistor.

- It is the main component of the HVAC system that controls blower fan speed.

What is the location of the blower motor resistor?

- It normally lies on the passenger side, close to the blower motor and below the dashboard. Each car has different locations of resistors, so follow the vehicle manual.

When did the blower motor resistor need replacement?

- its replacement is based on damage and working conditions. If damaged, soon replace it; if working well, it may take a longer time.

Can we drive with a damaged blower motor resistor?

- Yes, we can drive, but the fan speed does not vary; that affects comfort.

What causes a blower motor resistor to become faulty?

- The main causes for a faulty blower motor resistor are overloading conditions, moisture, and wear and tear, which can make the resistor faulty.

Is the blower motor resistor the same as the blower motor?

- No, both are different parts; the resistor controls the blower motor speed.

Can the blower motor work without the resistor?

- no since the faulty resistor stopped power to the blower motor. so the motor does not work without power. The blower fan has not moved since no power, and no air is moving through the vents.

What is the working life of blower resistors?

- Resistors work for the vehicle’s lifetime. But it can cause damage to the car. Since regular usage and overheating affect resistors, they wear out soon.

How much time taken to replace a blower motor resistor?

- It is based on damage and working conditions. since it is in the glove box that takes fifteen to twenty minutes for replacement