Hello, readers welcome to new post. Here we will learn Advantage of Stepper Motor. stepper motors differ in their features with a hybrid stepper motor that includes a 1.7×1.7-inch faceplate. With smooth rotation, they have 0.9 / 1.8 degrees per step and torque for good grip. This is often used in the installation of robot arms, 3D printers and many other applications. One can choose the required supply voltage and motor depending on the need of the application. They have a smooth design and are compact. They show excellent performance in terms of speed, torque, and step adjustment. In addition, disturbance factors such as current value, voltage magnitude, temperature change, and waveform do not affect the NEMA 17 stepper motor step value.

They have many more benefits than other types of motors used in industry Undoubtedly they outnumber any other type of car because of their distinctive features. However, the main advantage is its ability to allow for a prominent position and control the speed of motors. The feature has proven fruitful results when used in a variety of applications such as drawing, manufacturing, and industrial equipment.

The accuracy of the position

- In general, the normal use of a stepper motor while using it on motor-controlled objects is when we require high-precision positioning. It starts working when a normal DC engine fails with constant rotation when it can respond to the exact number of steps provided. In one turn a typical turn can be turned to 25600 steps.

- The number of degrees in each step on the stepper motor can cause the engine to move from a fixed position to another position given at any time in the circle. At 200 standard motors, it can reach up to 1.8 degrees per step. By using highly sophisticated series drivers, movement can be precisely controlled with systematic deceleration and acceleration curves are used. This method is very useful in controlling the process and using the volume when one needs to get special precision.

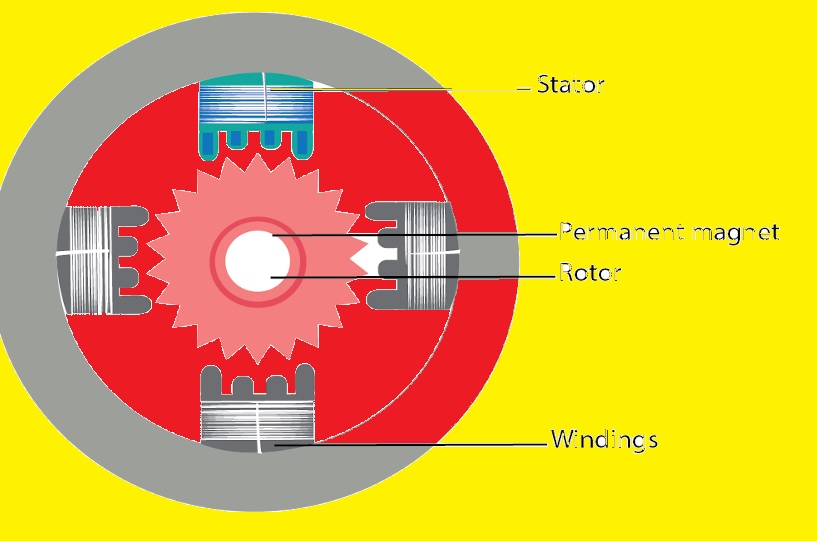

The performance of the stepper motor is greatly influenced by the construction quality of the vehicle used. Common features such as the quality of magnets and bearings are very important. Though the controller has an important role for the calculation of the power of the stepper motor It can convert digital input voltage and current into car speed and torque. Therefore, a key factor is their ability to start and stand in any position required with remarkable accuracy. By combining a stepper motor with a simple, intelligent car controller, we can achieve high performance and position accuracy beyond the scope of any other engine. These remarkable features find their way into many systems.

Advantages of Stepper Motor

High Precision

Its main advantage is that stepper motors have high accuracy. One of the most significant advantages of stepper motors is their high precision. Stepper motors can move in very small, precise steps, which makes them ideal for applications that require accurate positioning. Unlike other types of motors, stepper motors do not require feedback devices to ensure accurate positioning.

3. High Torque at Low Speeds

It has high torque for low speed which make is the best motor for applications where high accuracy and low speed are required They can maintain their torque even when they are not moving, which makes them ideal for holding applications.

4. Position Control

Stepper motors are known for their excellent position control. They can move in small, precise steps, which makes them ideal for applications that require accurate positioning. Stepper motors have the ability to move in clockwise and anticlockwise directions which makes it helpful for two-directional motions

5. Low Power Consumption

It uses less power during operation. Stepper motors used less power than other motors so used for projects where fewer operating power machines needed

6. Easy to Control

It can be easily controlled which makes it best for accurately controlling projects. It can be easily regulated through the use of controllers or computer that is helpful for automation applications.

7. Cost-Effective

It is a less expensive motor than other machines. They are easy to manufacture so considered as less cost motor

8. Reduced Vibration and Noise

Stepper motors produce less vibration and noise compared to other types of motors. This makes them ideal for applications that require low vibration and noise levels.

9. Reliability and Durability

Stepper motors are highly reliable and durable. It needs less maintenance during its operation that makes it a reliable and durable motor

10. Easy to Use with Microprocessors

It can be easily configured with microprocessors making it good for automated projects and robotic controllers