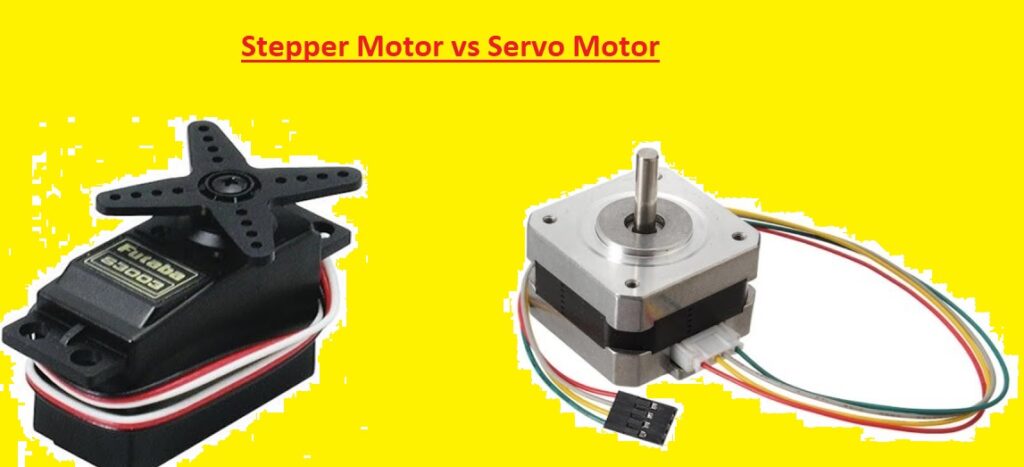

Here are two different types of motors, there is a stepper motor and a servo, an example of servo motor is HC-KFS43 and HC-MFS23. These are manufactured by the Mitsubishi servo motors on the market today. In this article, we will look at some of the advantages and disadvantages of these two types of motors and why servo motors are the best.

Here are two different types of motors, there is a stepper motor and a servo, an example of servo motor is HC-KFS43 and HC-MFS23. These are manufactured by the Mitsubishi servo motors on the market today. In this article, we will look at some of the advantages and disadvantages of these two types of motors and why servo motors are the best.

Both the stepper and the servo motor are used in automated processes where speed and accuracy are most required. However, the most important difference in how they work, the stepper operates in an open loop mode that does not require a response. Once the compulsory action is initiated the whole process is expected to be done automatically. So let get started Servo vs Stepper motors

Advantages and Disadvantages of Stepper Motor

Benefits

· There is no expected response which means it is self-sufficient, with the initiation of the remaining action step being taken care of. The motor itself acts as a local transducer thus maintaining accuracy.

· It is easy to operate and very safe in that in case of malfunction in some parts, the machine will shut down to prevent damage and cause damage to the operator.

· The engine is considered stable because even mechanical overload does not affect the machine.

· Most stepper motors are cheap and their operating costs are low.

Disadvantages

· These motors are very susceptible to resonance so they need to step a bit to work properly.

· The machine is noisy and noisy in high speed. This is a great danger for those processes that may tend to have less noise.

· The performance of these motors is very poor as no matter how much load they usually use a lot of power.

· Due to a lack of feedback, monitoring steps that may be missed is difficult.

Advantages and disadvantages of Servomotor

Benefits

· Motors work best with the use of power and the ability to handle the next job which is very profitable compared to the size of the car.

· The machines are quiet even at high speeds and have no resonance or vibration which makes them one of the most suitable engines for many automated processes.

· The accuracy and accuracy of the motors is very high compared to other motors, which are fitted with a connector that maintains accuracy and adjustment.

· Excessive heat is not a problem with these engines, although they have very heavy loads, they do not overheat

Servo vs Stepper motors

| Advantages of Stepper Motors | Disadvantages of Stepper Motors | Advantages of Servo Motors | Disadvantages of Servo Motors | |

|---|---|---|---|---|

| Precision | It has High precision and can move in small, precise steps. | It is not used for high-speed projects | It is highly accurate and can achieve high speeds and high torque. | It uses feedback devices for precise control. |

| Torque | It provides high torque at low speeds and also maintains torque when not moving | It is not used for high-speed projects. | It has high torque at high speed and maintains roque when not moving | It is more expensive than stepper motors. |

| Positioning | It comes with Excellent position control features and can move in both clockwise and counterclockwise | Not use for high-speed applications. | It also has excellent position control and can provide high speeds and high torque. | It needs feedback devices for precise control and higher cost. |

| Power | It uses less power. | Not use for high-speed applications. | it provides high power and high efficiency | It uses high power than stepper motors. |

| Control | It can be controlled with or computers. | Not use for high-speed applications. | It can be regulated with microcontrollers or computers. | It needs feedback devices for precise control. |

| Cost | Its maintenance is costly | not good for high-speed projects | Expesnive thenstepper motors. | Is structure is a complex and expensive control system. |

| Vibration & Noise | It causes less vibration and noise | Not used in high-speed projects | it generates less vibration and noise produced less vibration and noise. | Produce more vibration and noise than stepper motors. |

| Durability | It is highly reliable and durable and can operate for long periods. | Not use for high-speed applications. | it is reliable and durable and can operate for long time interval | May require more maintenance compared to stepper motors. |

| Size | It has a Compact size. | Not used for high-speed applications | Compact size. | Larger size compared to stepper motors. |

| Resolution | It provides High resolution and can move in small, precise steps. | Not used for high-speed applications | High resolution, can achieve high speeds and high torque. | Require feedback devices for precise control, and higher cost. |

| Maintenance | It needs Low maintenance. | Not used for high-speed applications | it requires low maintenance. | It need larger maintenance compared to stepper motors. |