The main component for performing the welding process is welding rods, which are important for providing good and strong joints. The welding rod is a small component but has a high impact on the welding process. There are different types of welding rods, each with its own features and uses. Here we will cover details of welding rods and their uses. So let’s get started with the best welding rods for beginners.

What Is a Welding Rod?

- Welding rods, also called electrodes, are welding materials that get melted and injected at the time of the stick welding process. To use a welding rod, first of all, connect with a welding instrument that will make an electric arc between the base metal and the welding rod. The high-power electric arc quickly melts metal and gets fuses for welding.

Structure of Welding Rods

Composition:

- The metal alloy in welding rods comes with the same composition as the metal welded. That provides good bonding at the time of fusion for providing quality joints.

Flux coating

- Welding rods come with a flux coating on their metal core that is used for different works. The flux makes a protective gas shield about the welding zone, offers alloy components for strength, and makes protective slag for good welding solidification.

Filler metal deposition:

- When the rod melts, metal is deposited on the joint from the rod. That filler metal comes with the same features as base metals, so the weld provides strength that is according to the surrounding materials.

Electrical conduction:

- Welding rod causes current from welding gun and electrode holder for controlling arc between rod tip and working component through welding process.

Different Types of Welding Rods

Consumable Rods

- A consumable electrode is best to use when the electrode and filler metal have the same features. if the electrode makes a connection with the working component and becomes a component of the molten weld puddle where the electrode, flux, and base metal are connected in the weld joint.

- Welding electrodes that are used with shielded metallic arc welding are consumable.

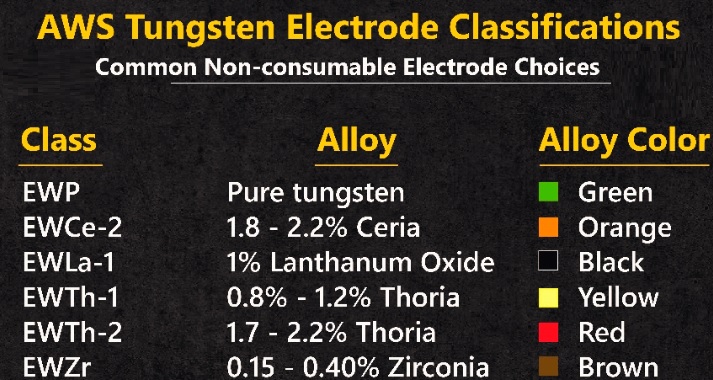

Non-Consumable Rods

- Non-consumable electrodes are based on Gas Tungsten Arc Welding (TIG welding).

- In TIG welding a non-consumable electrode is configured in a TIG torch and used for starting and holding an arc but not consumed into the molten weld puddle.

- The distinct bare metal filler is used in molten weld metal puddles for completing weld joints. The main type of these rods is tungsten electrodes.

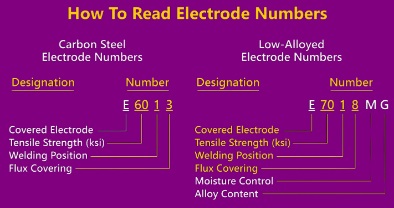

What is the meaning of welding rod numbers?

Welding electrodes or rods are defined based on the number written on the end of the welding rod in packages. The number defines the welder’s at-a-glance tensile strength rating, the rod position that can be used for welding, and the differentiated features of each welding rod.

The American Welding Society uses the system for defining welding electrodes based on strength, welding position, flux covering type, and alloying component for alloyed electrodes.

The numerical number is written on each welding rod and comes with providing a good decision for choosing a rod.

First 2 Numbers

- According to AWS details, the first two numbers and sometimes 3 numbers on the welding rod define tensile strength and features for resisting being pulled apart X 1000. Such as for denoting the 7018 number, 70 is that the weld made of 7018 has features to handle 70000 pounds per square inch of tensile stress.

- The welding using a rod defined as 11018 has features to handle 110000 pounds per square inch of tensile stress.

- The commonly used welding rod 6010 has a rating of 60,000 psi.

3rd Number

- The 3rd number is a position that helps to use the rod. A 1 means the rod can be used for all positions. A2 defines that rod used flatly and horizontally. Number 4 is used for a flat position.

Last Number

- The last number in the sequence defines the type of rod or any certain features, especially for flux covering. Such as the 7018 welding rod, which has 8, showing it is a low hydrogen rod having basic flux covering.

- The 0 in 6010, 7010, and 8010 is a type of fast freeze having cellulosic flux covering that is best for performing welding work. The 1 number at the end of 6011 is like a feature of 6010 and is used for AC power sources.

- For low-alloyed welding electrodes, the designation can come with alloy content in the last digit, as for E7018-A1, which shows that the electrode comes with 0.5% molybdenum.

Best Welding Rods for Beginners

E6010 Welding Rod

- E6010 is a famous and commonly used rod type. It can easily start the arc, provide deep penetration, and its spray arc features provide high traveling speeds. It has features to perform welding in all positions.

6010 Uses

- 6010 welding rod is used for making pipelines, gas plants, refineries, and utility piping with other types, 7010 and 8010.

- Its fast freeze feature helps to require skilled welders for filling gaps in joints. That can be difficult, if not easy to do, with other types of electrodes.

- Due to fast freeze features, 6010 welds do not come with the same ductility that we can get from 7018, so it is not a good option for cyclical stress or where ductility is important.

- For base metal, E6010 digs deeply, and its hot and high-speed working causes undercut and trapped slag inclusion.

- 6060 lies in the cellulose group of welding electrodes and has some amount of moisture processed in the rod.

- Its arc features cause more splatter, take cleaning time, and are high-cost rods.

E6011 welding rods

- The basic difference between 6010 and 6011 is that 6011 operates for AC power supply, and 6011 is called a farmer rod.

Uses

- In 1916 James Lincoln made an electric arc welder for use at a commercial level and sold welding machines for farmers in the Midwest.

E6013

- 6013 is an older standby for some light-duty sheet metallic applications since it comes with shallow penetration and high travel speed.

Uses

- For repairing older tractor fenders, this rod is best to use. For irregular weld joints and surface impurities such as paint and rust, rods can make fast and easy work for small repairs with good welds with less cleaning. This rod also works for AC power supply machines.

E7018

- It is also a commonly used welding rod that is part of a low-hydrogen welding rod.

Uses

- Some time ago there were issues found in subsurface cracking in steel buildings, bridges, and other designs. After finding some details, hydrogen is the main component of moisture that was found to be the main cause, and low-hydrogen series rods are used as staples in the structural steel welding world.

- E7018 does not move fast like E6010, but it is a fill-freeze type, and welds made with E7018 come with high ductility and are considered to be used for welds where ductility in cyclical stress is the main issue.

- E7018 produces good welds with symmetrical ripples and smooth contours for finishing welds with less splatter.

- Its main disadvantage is that if not stored accurately in a sealed container, it can absorb moisture in the atmosphere that can cause porosity in the welds.

E7024

- It is called a jet rod since it has high deposition rates; E7024 is good to use when needed to lay high metal.

Uses

- Larger structure beams, columns, and larger parts of heavy machines are welded with this welding rod. 2 in 7024 is a certain rod limited to flat and horizontal positions. For heavy parts of the plate with a relatively smooth joint, this rod can be used. It helps operators to weld with high traveling speed.

- Like E7018, the slag breaks off with less spatter in the accurate weld.

- The beginner and mid-level skilled welder must know that 7024 has a forgiving work angle and travel angle and needs to be focused on the molten weld puddle.

- E7024 also left small fusion voids in a weld that can move back and fix, especially for fillet weld joint features.

- DC power supply used with high amperage range for running rod.

E309L

- This welding rod is best for welding stainless steel. L in the name of the rod is low carbon; high carbon in stainless weld can reduce corrosion and define features of stainless steel.

Uses

- This rod is used for maintenance and preparing conditions. It is good to use for certain grades of stainless steel, but not used for absolute certainty. E309L provides a high deposition rate and good crack resistance.

- The 309 is best to use for different welders, and many welders keep small tubes of 309 in shops.

E4043

It is an aluminum welding rod that is highly versatile in nature and part of different grades of aluminum. Welding aluminum is also tricky to use for tougher positions. Due to the aluminum feature to conduct heat quickly, it can face more error than that of carbon steel electrodes.

Aluminum is a soft metal and absorbs anything that makes a connection with it, especially such things as grease and oils. Cleaning and joint prep are good when welding on aluminum. Muriatic acid and a wire brush can be good for this work. Like E7018 aluminum electrodes, they can absorb moisture, so it is good to store them in warm and dry places.

Tips for Beginner Welders

Quality Safety Equipment

- The welding process without accurate protective instruments can cause damage, so use quality instruments.

Helmet:

- Auto-darkening lenses come with different setting features, delay settings, and good optical clarity for less eye strain.

Gloves:

- Premium leathers with reinforced stitching and insulating wrist cuffs avoid high heat or rod cuts for hands and arms.

Clothing:

- Flame-resistant plants, jackets, and boots for avoiding burns as a result of sparks. Wool and cotton are combustible.

Earplugs

- Mild welding produces about 10 decibels of sound, so use earplugs to save your hearing.

Respirator:

- The use of a good fume-blocking respirator saves lung irritation at the time of welding.

Machine’s Output Range according to Rods

- Check that the welder’s amps, voltage ranges, and duty cycle provide features for the rod at the time of purchasing.

- Make sure that accurate polarity is used.

- Minimum and maximum diameter rods are compatible.

- Output god for joint thickness for selected rods.

- Inaccurate machine settings for rods cause poor welds and electrode damage.

Store Electrodes Properly

- Store rod in proper climate conditions.

- Avoid extreme temperature conditions.

- Store vertically to avoid flux coating damage.

- Use before expiry date.

- Some electrodes can handle humidity, and the cellulose type needs complete dry storage.

Frequently Asked Questions

Can we use low-cost imported welding rods?

Proper quality is important for learning, and an accurately featured rod has less error. So do not take the risk of quality.

How to read a welding rod’s classification number?

- The AWS standard defines details for rod composition and uses such as E6013. Read the cod as mentioned in the details above.

Why do rod welds keep cracking?

- Cracking is the result of impurity and fast cooling. Low hydrogen has resistance racking. Make sure that it cools slowly to avoid cracking, and also avoid rod moisture.

Can we weld aluminum with steel rods?

- Different metals do not fuse accurately. Use filler metal matching with base metal. For aluminum, use 4000 or 5000 series alloy rods.

Are thicker rods better than thinner wire?

- Match rod diameter with base for metallic thickness; find referred size range for packages. Thick rods needed high ampere settings.

What causes welding rods to be brittle?

- Moisture from improper storage causes hydrogen infusion in rods with time. Save sealed containers in warm and dry spaces for increased working life.

Why do my rod welds come with holes and splatter?

- The stick-out length that is going causes faulty welds. Maintain a half-inch or less stick-out, and increase the ampere for longer extensions if required.

How to remove stubborn slag after welding?

- Difficult slag needed simple chipping with a hammer and chisel. Avoid damaging softer welds; low hydrogen rods come with easy-release flux.

Can beginners use smaller-diameter rods?

- Yes, a 3/32 to 1/8 inch rod provides good arc control at the start.

What causes arc blow and wander?

- Tilting of the electrode tip is slight, and watching the travel angle affects blow based on electromagnetic field interference.