Hello, readers welcome to the new tutorial. Here we will learn Introduction to Injection Moulding. It is the manufacturing process of different substances through the practical implication of molted substrates. There are different categories of substances is used as molted material to make manufacturing material such as glass, die case, etc. This process is considered for such production generation applications where larges numbers are needed to construct having similar features.

Hello, readers welcome to the new tutorial. Here we will learn Introduction to Injection Moulding. It is the manufacturing process of different substances through the practical implication of molted substrates. There are different categories of substances is used as molted material to make manufacturing material such as glass, die case, etc. This process is considered for such production generation applications where larges numbers are needed to construct having similar features.

With glass, metallic, and elastomers, there is a common use of thermoplastic and thermosetting polymers. To get the required result of any product, synthetic resins are subjected to high temperatures and decreased temperatures to get the resultant design. Here, we will learn different parameters related to Injection Molding. So let’s get started.

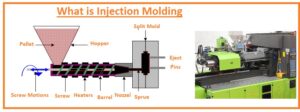

Working of Injection Molding

- First of all, there is mold is created through the use of different types of materials such as metallic components that are normally made of steel and in some cases aluminum.

- After the creation of molds through the use of machines placed in the heated bares with the implication of helical shape crew.

- Bands existing in the heating barrels melt the mold and reduce the temperature to make it hard.

- To make the cooling duration less, there is the use of cooling lines which has water circulation.

- Mold is placed at the plate molds, that is separated after the solid form of material.

- There is a process of single or multiple cavities that can be used of mold creation.

- In multiple cavities, there is similar featured parts exist with different feature parts that also lie to provide different modules.

- Due to deformation, wear, and easily damaging features, there is no preference given to aluminum in high-volume manufacturing.

- But steel molds are preferred and also have the disadvantage of high prices.

- After getting the detailed overview, we know that some complications exist in this process.

- SO handle the process for manufacturing process, there is a need for experienced services provided with reliable operation.

- To resolve this problem to get the rapid prototyping services i will suggest that you get high-quality products with reasonable prices the PCBWAY.

Another reliable option for precision machining and custom prototyping services is FS Fab, known for its expertise in CNC machining and injection molding solutions.

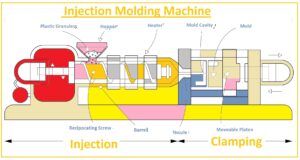

Injection Molding Machine

- The physical structure of the injection molding machine is discussed here. There are two main parts of the injection molding machine described here.

- The first one injection and the second one is clamping

Injection Unit of the Injection Machine

- The injection unit comes with different portions that are explained here.

Hopper

- It is a drum-like shape that is used to place the substance used for the molding procedure.

Reciprocating Screw

- It is used to send the substance placed in the hopper in the forwarding direction.

Heater

- Heaters are used to melt the material existing in the heaters.

Nozzle

- Through this point, the molted plastic substance is received.

Clamping unit

- It is the second main part of the injection machine that has further subparts.

Mold Cavity

- The molten material was placed in the hollow block created with steel, known as a mold.

Moving Plate

- When the product is cool, there is the elimination of molded material.

Where to Use Injection Molding

- It is normally used for different types of material such as plastic bottle upper parts, the body of your tv remote control, syringes, etc.

- That also applied in the automobile body parts construction such as in cars.

- It most preferred technique where large numbers of units having similar features are created. In simple words, used for large production.

Injection Molding Types

- Different types of injection Molding are discussed here.

- Gas-assisted injection molding

- Liquid silicone rubber injection molding

- Metal injection molding

- Thin-wall injection molding

- Micro injection molding

- Reaction injection molding

Injection Molding Advantages

- It is considered as the best option of a high-level manufacturing process. TO do this, there is a command given through programming software, and resultant products start creation.

- At PCBWAY, there are completely automated advanced-level instruments used for rapid prototyping services to get the highest results that help to lower the prices and faults occurring in the process.

- The use of high temperature injection-molded unit time is required for decrease process completion decreases. So in a shorter time interval, larger numbers of molds can be created.

- The use of fillers in the base resins decreases the plastic density used in molding and gives strength to molded portions. SO service offered by the PCBWAY for injection molding, robust and long-term operation of plastic substances and other manufacturing lacking these features.

Injection Molding Applications

- It is mostly the preferred technique for such a manufacturing process where large numbers of units are required at the same time interval.

- It is commonly used for manufacturing bottle caps, children’s toys, combs, spools, tables, and vehicle components.

- It is a very necessary technique used in the construction of plastic materials

That is all about Injection Molding I have explained all the parameters to apply these techniques for your manufacturing process. If you have any queries and want to get something else about these techniques, reach out in the comments. Further, i also have the most experienced and trustworthy services provider related to injection molding that is PCBWAY.