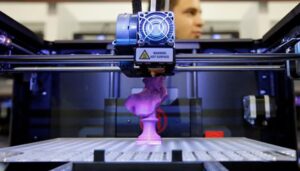

3D printing is a printing process performed through computer-aided design that makes different objects in a layer-by-layer configuration. The 3D printing process is part of the manufacturing and vehicle industries for making parts through 3D printers.

Since this field is growing fast, by 2029, the 3D printing industry will reach $84 billion. in this tutorial, we will cover details for 3d pirntingand learn where to get these services. Let’s get started.

What is the 3D Printing process?

- 3d printing process operated with computer-aided design for making 3d objects with the help of layering techniques. It is also called an additive manufacturing process, which uses different material layers such as plastics and biomaterials for object constructions of different sizes, shapes, and colors.

- In this process, 3D objects are constructed through digital files. An additive process makes 3D-printed objects, and in this process, objects are made by adding material in layer till final assembly.

- All layers are thin-sliced objects. It is also called volumetric 3D printing. Through volumetric printing complete design can be made one time without using layer-by-layer fabrication.

- The 3D printing process is the reverse of subtractive manufacturing techniques that cut out material blocks through milling machines.

3D Printing Services

JUSTWAY is a China-based 3D printing service provider and is growing rapidly in the manufacturing industry. The main objective is to provide quality CNC machining, 3D printing, and other relevant manufacturing services. They have been serving customers all over the world because they are committed to high accuracy, reliable operation, and customer satisfaction.

For quality 3D printing services, JUSTWAY operates with advanced technology and employs different materials. Either for prototypes or final assembly, their services provide a detailed conversion of design into quality products. The process is easy to access and transparent due to the use of an instant quote tool that helps with fast cost estimation according to design and materials. These features help make projects according to customers’ demands with quality.

Justway provides different material options, like different plastic resins, nylon, and metals, for making the required projects.

Their resin comes with high standards: transparent or semi-transparent resin and high-strength or high-temperature-resistant resin. that is best for making visual models, small parts, and prototypes,

They also included reinforced plastics or composite plastics like PA12 glass fiber reinforced nylon, PC, TPU, PETG, etc., preferred for different components like structural parts, heat-resistant parts, etc.

Their materials are aluminum (AlSi10Mg), stainless steel, titanium alloy, tool steel, etc. With SLM techniques, they make metallic components that have high metallic strength and functionality.

If you are new to JUSTWAYand want toget 3d printing service or any other will get a $5 coupon as a website user.

What Are 3D Printers?

- 3D printers employ CAD for making 3D objects with molten plastic or powders. 3D printers are in different designs and structures that fit in larger structure models for 3D-printed configurations.

- 3d ptiners has 3 main types and each work different methods

Are 3D Printers Important for the Future?

- Flexible, accurate, and high-speed operation of 3D printers makes them the best for the manufacturing industry. They are also part of rapid prototyping.

- Different manufacturers use 3D printers for making prototypes in a shorter time than a longer time-taking process.

- Some industries said 3d printers’ process can reach ten time fast and with a lower cost than R&D processes.

- 3d printers are also important for different industries. Not only do they perform prototyping, but printers also produce finished products. The construction industry is also employing this printing process for home designing and construction.

How Does 3D Printer Work

3d printing belongs to addtivie manufctring process and employes same process asconventional inkjectprinter for 3D design. additive manufcturing define process for making layers using differentmaterialsvtill final design is finished. This process is also called molding and 3D printing.

Here are some steps explained for the 3D printers’ operating process.

3D Software

- First of all, for the 3D printing process, 3D modeling is done. to increasing maximizing all produts design with 3D modeling software.

- Some designs were difficult to make and needed details for the conventional manufacturing process. So CAD sotwares are used

- Modeling helps printers to make customized products with fine detail. 3d modeling software features for accurate designimportantfor industry.

- modleing softwareimportantin industries like the medical field, where 3d software designs teeth for dentistry design, with that also important for aviaitonindustry

Model slicing

- after making a model slice cut becauses 3dprinters not have features for conecptulizaing 3d conecpt, such as we slice model into layers for printing to make the final assembly.

- Slicing software makes each layer scan the model and gives the printer an indication for making those layers. slicers indicates 3d printers to fill the model, which will provide 3D-printed objects with inner lattices and columns for design and a strong layout of the product.

- After slicing the model, it delivers in 3d pritners for the printing process.

What is 3D Printing Process?

After finishing the modeling and slicing of the 3D component, the 3D printer starts operating. printers used like conventional inkjet printers for direct 3d printing process, in this porcess nozzle moves and dispenses wax or plastic polymers in layer by layer form after that they become dry, and after that again process starts again.

it apply many 2d prints on one another for a three-dimensional object.

3D Printing Materials

Different materials used for printers for making objects are

Acrylonitrile Butadiene Styrene

- plastic material haseasy sahping change process anddifficut to break.

Flexible Filaments

- these filament make printst that can bend but high strength. These materials are employed for printing small watches to larger objects.

Metal Filament

- this filametns created through ground metals and polymerglue. It comes in brass, bronze, steel, and copper designs for getting an accurate design and proper metallic object functioning.

Carbon Fiber Filaments

- Carbon fiber is employed for making objects for making strong designs with low-weight features

Conductive Filaments

- These materials are in the experimental process and are employed for printing circuits without using wires. it is preffered for wearable technology.

Wood Filament

- This filament comes with ground wood powder in a mixture of polymer glue. It is used to print wooden objects and shows designs like low weight according to the printer temperature. 3D printing processes take some hours for easy prints to complex objects like balls, boxes, and full home designs.

Types of 3D Printers

Commonly used types of 3D printers are stereolithography (SLA), selective laser sintering, and fused deposition modeling (FDM).

Stereolithography

- Stereolithography was the first 3D printing method, which was first used in the 1980s and is also famous among professionals. SLA 3d printers work with a laser for curing liquid resin in hardplastic with a photopolymerization process

- SLA resin 3D prints are commonly used for features to make high-accuracy, watertight prototypes and isotropic components for different materials with smooth features and a smooth surface finish.

- SLA resin formulations come with different optical, mechanical, and thermal features for providing engineering and industrial thermoplastic solutions.

Selective Laser Sintering

- SLS 3D printers operated with high-power lasers to sinter small components of polymer powder into a solid design. Unfused powder supports the component when printing is performed and reduces the use of the supported design.

- So SLS is preferred for complicated geometries, like undercuts, interior design, walls, etc. Parts made with SLS printing come with good mechanical features and high strength for the assembly of injection-molded parts.

- Nylon is a commonly used selective laser sintering material that is common for engineering thermoplastics due to its good mechanical features.

- Nylon has a lower weight and high strength, and is also stable enough to withstand various effects, such as heat, UV light, and dust.

- Their low cost and high productivity make SLS best for functional prototyping, and a low cost solution for injection molding.

Fused Deposition Modeling

- FDM, whose other name is fused filament fabrication (FFF), is a commonly used 3D printing type at lower levels. FDM 3d printer operated through extruding thermoplastic filaments, like Acrylonitrile Butadiene Styrene), PLA, through a heated nozzle, melts materials and apply plastic lasyersfor makingdesign.

- each layer applied tll complete partmade

- FDM 3d printers preffered for basic proof concepts model also low cost prorotping of basic components, like parts that are machined.

- FDM comes with less resolution and accuracy than SLA or SLS and is not preffered for complex designs and parts.

- High-quality finishes are achieved with chemical and andmechanical polshing techniques. Industrial FDM 3D printers are used to solve these errors and provide different engineering thermoplastics.

,