The battery reconditioning process is used for restoring at the required performance level. With time, batteries lose capacity for holding a charge due to different factors, like use, aging, and environmental conditions. The main purpose of reconditioning a battery is to restore original battery conditions, helping to maintain the required working life and capacity. In this post, we will cover the detailed process of battery reconditioning and its importance. So let’s get started.

What is Battery Reconditioning?

- Battery reconditioning is a technique where electrical and electrochemical restoration is performed for partial recovery of battery performance through recharging batteries.

- The main purpose is to restore battery conditions instead of replacing them through avoiding degradation through lead sulfate crystallization of lead acid batteries or voltage imbalance through lithium-ion packs with controlled charging and cell balancing, also with pulsed current

- Battery reconditioning is not meant to reconstruct damaged electrodes or restore new battery-like features.

- When reconditioning is applied to a battery during the degradation phase, it makes the battery stable for vehicle, backup power, and lighting applications.

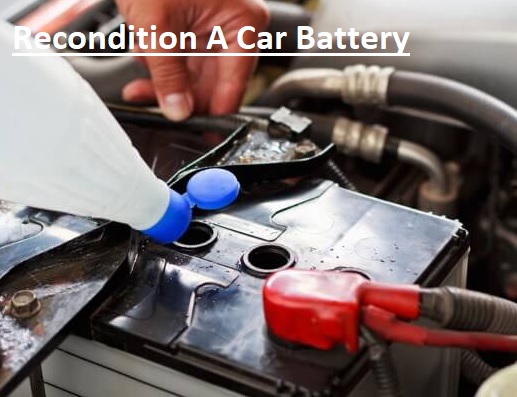

How To Recondition A Car Battery

Cleaning

- In this step, corrosion is cleaned. For this purpose, a certain cleaner is used to make a solution to clean battery terminals. For cleaning purposes, different cleaning materials exist. For making a cleaning solution, mix baking soda 2 teaspoonsand one water teaspoonfor making passte assembly. Now, with the help of a toothbrush, clean the terminals. If strong corrosion exists, steel wool is also employed.

Check battery voltage.

- In this step, check the battery voltage for restoring conditions. A voltage tester or voltmeter is used for testing battery volts, which helps to get an accurate power value. To check the voltage, make a connection of the voltmeter with the battery terminals and check it.

- Reconditioning of a car battery defines that the battery voltage value as larger than 10 volts. If the value is less than 12.6 volts, the battery is in good condition, and if the value is high, it needs reconditioning.

- A voltage value between 10 and 12 volts restores the battery to a fully operating condition.

- if voltage is less than 10 volts, it means the battery has degraded highly and needs to be checked with mechnaic

Remove acid.

- In this step removed old acid in battery. For this purpose, use a flathead screw for opening battery caps. Cap can come with 2 to 6. So, remove all caps, and before that, arrange the container close to you.

- before releasing the acid test for each battery cell. This helps to indicate whether the car battery has a dead cell or not. If you find cells of the battery are empty, put the battery on its side, use half a pound of baking soda, and add it to the old battery acid container. It neutralizes battery acid that can easily be disposed of.

Set the battery in working order.

- After cleaning the acid from the battery, it is now ready for reconditioning. So add an electrolyte to the cell. Electrolyte is made with distilled water and Epsom salt. That helps the battery to charge and prevent sulfates. So after making it, add in the battery.

Charge the battery

- In the last step of reconditioning the car battery, check if the reconditioning process is functioning or not. not referred to use the cap again on the battery since electrolyte releases at the time of charging. So connect the battery charger negative pin with the negative pin and the positive pin with the positive terminal.

- Maintain a charging speed of about 12 V, 2 amps. Maintain the charger for about 2 days.

- Remove the charger and get values with a voltmeter. Normal readings show 12.42 volts.

Different battery reconditioning techniques

High-flow charging process

- Using high voltage and high current for charging lead-acid batteries helps to eliminate vulcanization. During this process, high voltage and current charging increase battery temperature. As a result, the plate becomes soft and deshaped and it affects the inner battery design, which makes this reconditioning process not usable.

Sulfation repair

- Repairing devices used for vulcanized batteries with the application of fuzzy numerical control features. through checking battery conditions, anode and cathode frequency transformation components, wave releases when charging and discharging processes are used, and hard lead sulfate is converted to crystallized battery and eliminated in 10 to 20 hours.

Water loss repairing method

- The repairing process involved adding pure water, potassium sulfate, and sodium sulfate to the battery, with charging and discharging occurring.

- These repairing techniques help to restore 80 percent quality lead-acid battery capacity in one year, and it is a mainstream battery reconditioning technique since it is easy to function and makes repairing an easy process.

Shallow cycle high current charging techniques

- shallow cycle chargeand discharge battery pack carried with the help ofhigh current 5 amps in a sulfide lead-acid battery pack.

- When charging is completed, shift the power to thirty percent. Repeat it many times to check the charging and discharging process, temperature does not cross 45 degrees.

- This process comes with special repairing factors for light vulcanized batter but less impact on severely vulcanized batteries.

Pulse repairing technique

- rehydrated needed for electric vehicles that helps to increases car battery’s working life. Hydration tools are used through the use of glass and plastic straws. For easy applications, process medical disposable syringesalso employed for easy measurements.

- Rehydration tools do not employ metal-made utensils, and syringsused after eliminatingmetalic needle andconnect plastic tube there.

Why is Battery Reconditioning mostly used?

Some causes of reconditioning a 12V battery are important.

low cost

- The normal cost of a new battery is 150 to 500 dollars, according to chemistry and vehicle requirements. Reconditioning provides a low-cost option mostly for older vehicles.

Environmental features

- Longer battery life minimizes wastage that resonates with environmentally conscious drivers.

Reconditioning Limitations

Overheating

- Overcharging results in heat generation. Heat generation causes plate shedding, resulting in a gas expansion sealed design, and causes boiling of the electrolyte. A battery that becomes heated during reconditioning has limitations.

damaging the battery

- For some days, the battery is revived and can show an accurate appearance with inner degradation regularly occurring. It results in faults.

Bad start-stop batteries

- EFB and AGM batteries do not manage uncontrolled charging cycles properly and need accurate current with voltage control. With unregulated charger devices, operating life is affected.

Contamination

- liquid battery restoring additive resulting in sulfation dissolving different contamination electrolytes, affecting plates, and also the battery’s inner chemistry.

Structural Damage

- battery having short warped plates, less electrolyte, affecting reconditioning badly, and if we try to restore it, resulting in a faulty charging process.

Frequently asked questions

What are the signs that battery reconditioning is done?

- Two main signs that show battery reconditioning is finished.

- The first one is a charger; a reconditioning charger gives a signal about process completion, normally with a light on or a complete display. After that, it will shift to trickle mode.

- Another method is to give some time to the battery for some hours and check the voltage. so accurate working battery holds a stable charge with 12.6 with12.6v or larger

How long does a battery need to be reconditioned?

- Battery reconditioning generally takes four to 24 hours. That is based on battery condition; a highly sulfated battery takes a longer time to charge.

- The charger’s connected power and type also affect the reconditioning mode when charging occurs.

What does “battery recond” mean?

- Battery reconditioning is the process of battery, which shows a controlled battery restoration function with the help of a certain charging process.

How does battery reconditioning work?

- battery reconditing occus with the reverse of reversible degradation, like sulfation or cell imbalance with controlled current, cycling, and voltage

Is a battery reconditioning charger needed?

- Yes, it is needed for safe operations. The battery reconditioning charger offers accurate control compared to the manual process.

What battery categories can be reconditioned?

- AGM, gel, NiMH, lead acid, and lithium-ion batteries are reconditioned if degradation does not get to a faulty phase.