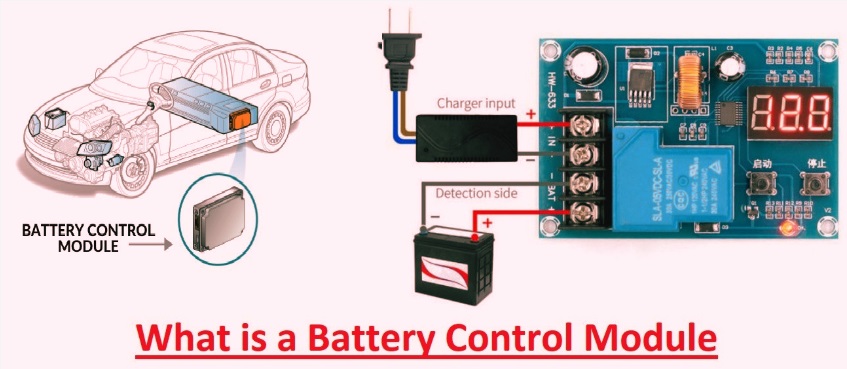

The battery pack is the main energy source for different devices, offering power to functional devices. The main design of the battery pack comes with a metallic shell casing and a modular structure to make the connection of battery cells. The battery management system (BMS) increases battery working life and denotes battery status. In this post, we will cover features for the battery control module and related factors that make it a main part of the battery management system. In this post, we cover the details and features of the battery control module.

What is a Battery Control Module?

- The battery control module component is the main part of the battery management system that performs management and battery status monitoring.

- It comes with a microcontroller chip that checks battery health and charging status by using data measured with the cell supervision unit and battery junction box.

- The battery control module provides normal operation with safety features. When BCM fault codes are shown in the electronic control system, the vehicle system shows faults with the brake or sensor circuit.

Components of Battery Control Module

The battery control module comes with software and also hardware components for handling monitoring, control, and protection used for certain battery chemistry and pack design. The main components of the battery control module are

Sensing Circuit

- The voltage and current temperature sensor helps to perform calculations input at the BCM. Accurate sensor data helps proper cell monitoring and offers control decisions based on charging and load balancing with protection measures.

Signal Conditioning

- Sensor signals needed adjustments such as filtering or amplification processes before being supplied to BCM ADC and controllers. Certain types of ICs manage operations such as sensor excitation, anti-aliasing, and offset adjustment.

Microcontroller

- Microcontroller design, main processing of the battery control module. It operated BMS algorithms and converted measuring data into control instructions for balancing circuits, contractors’ thermal systems, and other parts.

Communication protocol

- System interfaces such as CAN, LIN, and Ethernet protocol offer communication between BCM and external controllers such as inverters, batteries, or vehicle control units.

- Communication protocols offer important data sharing with diagnostic features.

Balancing Circuit

- An active or passive balance structure in BCM provides uniform cell charges. MCU causes a balancing circuit according to the route current over cells or dissipates extra energy in resistors

Power Supply

- BCM comes with a variable power supply circuit for making stable supply rails for ICs, power sensors, and controllers. Linear and switch-mode regulators are used to increase efficiency.

Battery Control Module Functions

The battery control module is used to perform different operations simultaneously. Each operation is important for making effective, safe, and stable operations.

Battery condition monitoring

- This module performs measurement of cell voltage at the system level. The current movement occurs in and out.

- temperature of the battery pack and charging state, and battery health

- This information is helpful for early detection of faults and setting functions before any damage. For larger projects, this monitoring is important for system optimization and maintenance.

Battery system protection

- Battery protection is also a main feature of the control module. It has features to respond to different fault conditions, like over-discharging, overcharging, overheating, high current, and internal cell imbalance.

- When these conditions occur, the module stops the power supply to avoid damage.

- This protection is important for high-power projects like grid support, peak shaving, and backup power.

Charging and Discharging Control

- The battery control module defines energy flow in and out of the battery. It manages charging rates, discharging limits, and response time according to system conditions with functional demand.

- Batteries must provide high-speed response loads, energy shifting, and backup power. Accurate control helps the battery to offer power according to requirements without affecting the cells.

Cell Balancing

- For multicell battery systems, single cells do not degrade at the same rate. Some chargers are high speed, and others lag. The control module balances cells so all cells function at the same level.

- This balancing provides longer battery working life, capacity, and system reliability, and energy efficiency.

Communication With External Devices

- • The battery control module has features for communicating to other components of the energy system. that share data with investors, monitoring systems, energy management systems, grid connections, and backup power controllers

Different types of battery control modules: Features

Function features

- Some types of battery control modules come with basic charging and discharging control features, while high-end control modules offer different operations like battery balancing, remote monitoring, and fault diagnosis. Intelligent battery control modules perform monitoring of different factors like voltage, current, and temperature of the battery, and adjust charging and discharging features for these factors to enhance working life.

cost differences

- The cost of normal battery control is less and is in the range of tens to hundreds of dollars, and the cost of control modules that cause complicated operations and advanced features is higher, about thousands of dollars.

Quality factor

- High-quality battery control modules come with quality components and materials and a stable design, and provide stable functions in harsh conditions. Some low-quality modules cause errors, like coming with low-quality materials and components, and these low-quality materials result in faults that affect battery operations.

appearance

The appearance and design of battery control modules from different brands and models may vary. Some control modules are compact in size, making them easy to install and carry, while others are larger in size but may have better heat dissipation performance and protection levels.

BCM Features

- Main features of battery control modules are as follows:

Good Safety and Abuse Tolerance

- BCM manages safety hazards such as thermal runaway under increasing vibration, mechanical shock, and faulty electrical loads. That is important for clearing abuse tolerance tests.

Longer working life

- Through properly balancing cells and controlling effects on overcharging and overheating, the battery control module increases the working life of battery packs.

High Efficiency

- BCM data controller for optimizing charging and discharging processes for high efficiency and use of battery packs.

System Integration

- Standard communication interfacing helps BCM for easy transmission of data to other systems through easy plug-and-play connections

How to test the battery control module

Different testing features are applied for accurate performance for reliable operation of the BCM design.

Functional Test

- This test offers accurate monitoring, proper control balance features, and communications connections through varied working features.

Environmental Test

- It provides durability testing of the enclosure, connectors, and internal structure when facing vibrations, humidity, and temperature variations.

Protection Test

- It ensures the activation of the safety mechanism in overload voltage and overcurrent conditions.

Compliance Test

- It follows electrical and environmental safety standards and functions with regulatory options. Design clear certification testing and certification protocols for employees in battery-based projects.

Symptoms of a faulty battery control module

Different signs of a faulty battery control module are

The device cannot start.

- It is a basic sign that the battery control module is not operating. If any faults occur in the controller, as a result, the vehicle loses power and does not start accurately.

Charging system faults

- • The main operation of the battery control module is to control the charging and discharging battery process. If the controller does not operate well, facing errors like slow charging speed, difficulty charging, or issues during charging occurrences

low battery life

- The battery control module does not control charging and discharging the battery in the proper way; as a result, the battery has a chance of overcharging and discharging, which affects operating life.

warning light on

- If the battery control module is not working, electrical devices show warning lights to indicate a fault of the battery.

- If a fault occurs in the lithium battery controller, certain reasons should be detected and then a related solution should be found. To control battery control module damage,

- inspect and maintain the battery and controller for proper condition. Do not use devices in extreme conditions to avoid battery damage or controller damage.

- Connect the required charger to the charging process.

Battery Control Module vs. Battery Management System

The battery control module and battery management system are different but sometimes considered the same. The battery control module is hardware and core operations for real-time protection and control operations.

A battery management system comes with a control module with software, a monitoring system, and a communication protocol.

| Feature | Battery Control Module (BCM) | Battery Management System (BMS) |

| Function | it regulate battery modules to perform a function. | it handle complete battery pack completely like different modules |

| Components | balancing circuits, Voltage and temperature sensor microcontrollers, | different BCMs, data processing unit, cooling system |

| Uses | Electric vehicles, energy storage, | Large battery packs of EVs, grid-scale energy storage, and industries |

What is a battery pack?

- The battery pack comes with different battery cells connected in a certain design to make a uniform power supply. These cells are connected and covered in a protective casing for safe operation.

- cells’ connection in a lithium-ion battery pack used for optimized function and voltage output in certain projects.

- Battery packs are part of portable electronic devices, EVs, and synergy storage for a constant supply