For checking the oil pressure of the car engine, the oil pressure sensor, also called a pressure sending device, is used. It is the main part of the vehicle’s engine management system. This part helps the engine to work in the required oil pressure ranges that provide accurate lubrication and avoid any damage. The sensor has a diaphragm that monitors and operates if any changes occur in oil pressure.

In this post, we will cover the detailed features of the oil pressure sensor and related factors. So let’s get started.

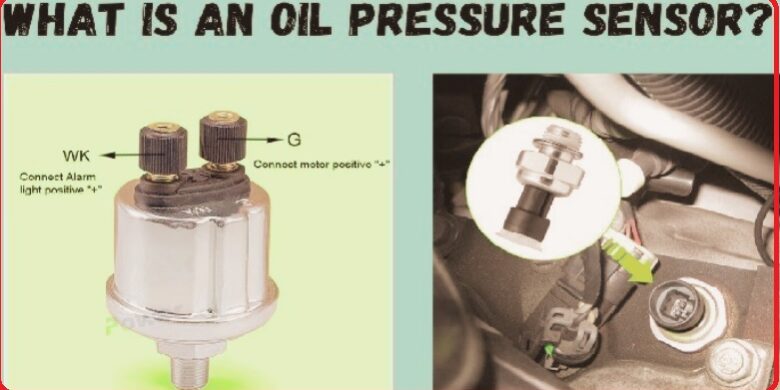

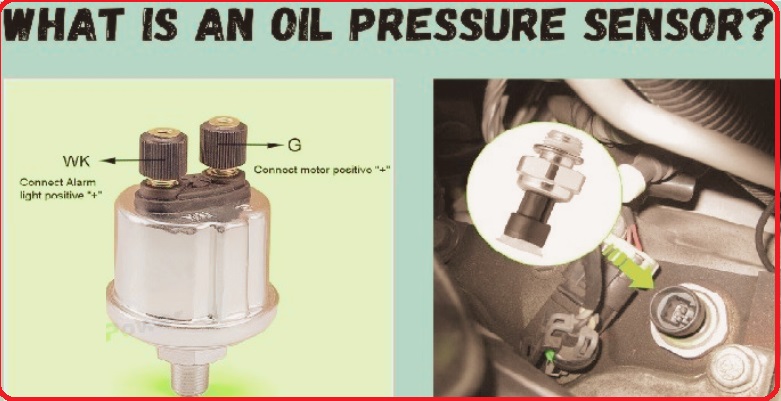

What is an Oil Pressure Sensor?

- The oil pressure sensor is considered a crucial part of the car engine. Its main function is to monitor the lubrication system’s oil pressure.

- The engine lubrication system functions to provide pressurized oil to the rotating and moving parts of the engine. The oil pump gets oil from the oil pan and sends it to the lubrication system after filtering.

- After that, oil is transmitted to different bearings, camshafts, rotating parts, and engine moving components.

- If oil pressure does not exist, the engine will not operate for long. The oil pressure sensor is connected to the cylinder block near the oil filter part.

- Oil pressures come in two types, which are oil pressure switches that control the electrical circuit for low-pressure demand and operate as oil pressure sensors, like real oil pressure.

Oil Pressure Sensor Working

- oil pressure alarm operates when deviations occur from the set value. The oil pressure sensor comes with two main components: a diaphragm and a spring-loaded switch. The engine block control pressure switch is connected to oil storage.

- When oil pressure on the diaphragm increases, the spring pressure switch gets a high force to separate the electrical contacts on the warning light.

- The diaphragm reduces pressure on the spring, which causes the switch contact to show an alert during driving when oil pressure is below the required value.

- The dashboard warning light shows that low pressure exists and blinks if any low level of oil pressure exists.

- If the light continuously glows, it means oil pressure has completely decreased. Current flows from the fuse towards the oil pressure switch when the engine operates, turning off the oil warning lights.

- If the oil pressure is more than 4.3 PSI, the diaphragm connection is separated and the oil pressure light operates.

Main Functions of Oil Pressure Sensors

- oil pressure sensor main part that maintains the engine’s working condition. it manages fuel efficiency and working performance through connection with the engine control system. its main functions in vehicles are as

Read also :The Role of Smart Sensors in Material Processing: Quality Control

Oil Pressure monitoring

- An oil pressure sensor’s main function is to monitor engine oil pressure to set it in the required range. As it is close to the oil filter or oil flow path, this sensor measures circulating oil pressure. It affects engine lubrication, so circulating oil pressures are accurately measured.

- Accurate lubrication minimizes the friction of engine components, controls overheating, and prevents damage to engine parts.

- For low oil flow, the engine does not have the required lubrication, causing high friction and damage.

- In results, high pressures affect gaskets and cause damage. Sensors monitor oil pressure and show it on the dashboard of the car, which helps to know about engine health and ensure the vehicle is working well or not.

Engine protection from damage

- • The oil pressure sensor’s main function is to control any damage to the engine due to any abrupt pressure changes. Low oil pressure reduces lubrication, which causes overheating of moving components due to lack of lubricant.

- High friction occurs due to low lubrication, which causes damage to the engine. If oil is moving with high pressure, then the required pressure damages the oil flow path and also affects the gaskets.

- So proper oil pressure monitoring and maintaining the required range: the sensor transmits safe pressure to the engine and avoids moving parts. In this way, parts work safely, and overall efficiency increases.

Car Warning System integration

- oil pressure sensor connected with the warning system of the vehicle, which gives signs about any fault of the engine. If there is a change in the oil pressure signal sent to the vehicle display system, a warning light gets on.

- That helps to take preventive measures for checking oil level before any damage.

- The warning system is used as the first indication of any fault and avoids any serious engine fault.

- In advanced cars, the latest sensors are used, which give clear fault details and make the troubleshooting process easier.

- It increases vehicle safety and long-term working.

Engine Health monitoring

- • The oil pressure sensor not only monitors pressure but also gives details about the overall condition of the engine. An accurate level of flow of oil and pressure is preferred for moving component lubrication and providing the required engine temperature, and changes in pressure level cause any error.

- If oil pressure reduces, bearings can be damaged and oil paths can be clogged.

- High pressure causes blockage or affects the pressure relief valve. The sensor detects these errors and avoids damage to the engine, like engine overheating and other faults.

- Proper engine health monitoring helps to do proper maintenance and repairs that increase engine working life.

- The oil pressure sensor, which does not provide accurate lubrication, also works as a diagnostic tool for proper engine working.

Engine Control Units (ECUs) are connected with sensors

- In advanced vehicles, oil pressure sensors are configured to the engine control units for longer working performance. The sensor gives feedback to the ECU for optimized lubrication, sets the oil flow, and aligns the required engine temperature.

- With this configuration, the engine works effectively in different conditions. Through maintaining proper lubrication, the ECU provides fuel efficiency and reduces damage to the engine.

- ECU stores data about any pressure variations and helps to identify errors before serious faults.

- Proper collaboration between the oil pressure sensor and the ECU helps to increase engine efficiency and working life.

Oil Pressure Switch vs Sensor

These two components are used for oil pressure monitoring but come with different functions. basic different areas

Functions

- oil pressure switch on/off device that operates a warning light when oil pressure is less than a certain defined value.

- While the oil pressure sensor gives continuous details about oil pressures, it helps us to regulate engine conditions at any instant.

Output

- Oil pressure gives binary results, which means the warning light is on or off. The oil pressure sensor gives numerical output about pressure values.

Diagnosing process

- The diagnosis process of these two devices is different. The oil pressure switch monitor through the warning light on the state and alarm is working.

- oil pressure sensor, uses a diagnostic tool for getting the reading of the oil pressure signal and checking if it is in the given range

Cost

- An oil pressure switch costs less than a pressure sensor. since both have different functions and design complications

Main Causes of Oil Pressure Sensor Damage

Different factors cause oil pressure sensor failure. that affects the working and related factors of the sensor.

Dust particles

- The sensor gets clogged with dust and sludge if engine oil is not changed. Dust and other particle accumulations make sensor readings faulty and affect the pressure level.

components, degrading

- With the passage of time, different components of the oil pressure sensor are affected due to different conditions of the engine. The resistance component of the sensor get corroded, which affects the oil measurement capacity of the sensor

Oil Leakage

- If there is a leak in parts where oil flows, it affects oil pressure; as a result, the sensor’s working is affected. Oil leakage also affects the sensor surface and affects the working

Electrical faults

- Above, we discussed that there is a connection between the ECU and the oil pressure sensor for data transmission; that connection is made electrically. Bad connection affects data transmission, causing faulty reading on ecu

Mechanical parts damage

- If faults exist on parts like the oil pump for oil flow, it causes low pressure of the sensor reading and affects performance.

Manufacturing faults

- It is not common, but some faults can occur during the manufacturing of the sensor and give reading errors during the sensor’s operation and cause failure.

Installation faults

- If the sensor is not connected accurately, like not having proper sealing, it can cause leaks or affect performance.

Temperature condition

- Sometimes, a sensor faces different temperature conditions, and working in harsh conditions can cause damage to the oil pressure sensor.

Signs of a Faulty Oil Pressure Sensor

There are different signs that show the oil pressure sensor is not working well.

The warning light comes on.

- A warning light means oil pressure is low, which indicates faults in the engine and requires serious attention to solve.

- If the sensor is faulty, it causes light to blink.

Faulty Oil Pressure Gauge Readings

- A faulty pressure gauge reading also shows a bad sensor is working. There can be faulty needle movement if the needle shows bad results, like high readings when the engine does not have a fault and then becomes zero without any indication.

- In this way, we cannot find either an error due to a bad sensor or an oil pressure error. But some signs, like an effect on the oil pump or a blockage in the oil path, mean the sensor is not working well.

Engine Noise producing noise

- The engine produces noise when the oil pressure reduces to the required level. Noises are knocking sounds that occur when metallic materials connect without lubrication.

- The engine also produces rattling sounds due to the valve train when oil does not flow accurately.

- Noises show that engine components do not have proper lubrication and cause damage.

- So the best thing is to check the oil level and pressure after stopping the vehicle, since low pressure while driving causes severe engine faults.

bad Engine Performance:

- bad engine is commonly seen in advanced vehicles if the ECU is getting faulty data. The ECU works based on data to set the engine to work.

- If the oil pressure sensor is not working well and showing faulty values, it causes high-level errors. In a result, it faces low power and affects engine working.

- Bad acceleration also stops increasing engine speed. It also affects engine efficiency and causes high fuel usage.

Check Engine Light

- Checking engine lights get on due to a faulty oil pressure sensor if the ECU is showing abnormal oil pressure readings. The check engine light also shows different faults, so you must identify which fault is causing the check light to come on.

- If we do not consider it, it seriously affects the engine badly, since the accurate value of oil pressure provides accurate engine working.

- A diagnostic scan helps to differentiate error codes based on the oil pressure sensor, which helps to perform troubleshooting accurately.

Oil Pressure Sensors types

Mechanical Pressure Sensors

- It operated with a Bourdon tube and a diaphragm for measuring pressure. It shows pressure mechanically, but does not give results in digital form. so not used for modern electronic systems.

Electrical Pressure Sensors

- This module transforms pressure into an electrical signal with a diaphragm and transducers. It is commonly used in vehicles and connected with a digital control system and gives the required results.

Variable Resistance Sensors

- It is used for measuring pressure with resistance change and change in oil pressure. It is low cost and simple in design, but it wears with time and gives faulty readings.

Hall Effect Sensors

- It produces high voltage signal in direct relation with oil pressure with the help of the Hall effect. It provides high accuracy and reliable working and is less affected by wear than a variable resistance sensor.

Piezoelectric Sensors

- It employs piezoelectric crystals for producing electric signals according to pressure. It is sensitive in nature and gives a fast response, and it is used for different projects.

Magnetic Sensors

Read also Top 10 Best Wireless Wii Sensor Bars

- It measures pressure by detecting magnetic field distortion that occurs due to pressure variations. It is part of some advanced vehicles.

Combination Sensors

- It operated with the function of an oil pressure switch and sender. It gives a warning indication and accurate results with the same module.

Silicon-on-Sapphire Sensors

- It provides high accuracy and stable working with the help of advanced techniques. It gives highly accurate results and is part of difficult conditions.

How to replace oil pressure sensor

Here are some steps explained for replacing the oil pressure sensor. Follow them.

- First of all, arrange the tools required for performing the replacement, like a socket set, wrenches, and other tools.

- Now follow the vehicle manual for finding the location of the oil pressure switch or sensor. that normally exists close to the oil filter.

- Now disconnect the oil pressure sensor connector for the disconnection of the pressure sensor. Handle the connector for any damage.

- Now remove the oil pressure sensor with a wrench from its connection point. Do this process without damaging any component.

- Now connect the new sensor at the atsame point where the faulty one was removed. Tighten the sensor with a wrench without overtightening.

- Now connect the electrical connector with the new oil pressure switch for a strong connection.

- Now start the engine and make sure that the warning light is on or not, and if an accurate reading is shown on the dashboard, that means it is working well.

How to maintain oil pressure sensors

Follow these steps for a longer working life and maintenance.

- Change oil regularly to avoid any sludge creation in oil that clogs the sensor.

- employs quality oil and filters for minimizing the contamination and increasing the working life of the sensor.

- Regularly check the engine for leaks that can damage the pressure sensor and affect functions.

How to Test Oil Pressure Sensor?

different testing methods used for finding the accurate working of the pressure sensor; some tests are as

Visual Inspection

- with the visual method check that there is no oil leakage that shows any damage. Check that the electrical connector is strongly connected and does not have corrosion.

Manual Pressure Test

- For this test, an oil pressure gauge and adapter were used.

- First of all, disconnect the sensor from the connected point.

- Then manually connect the pressure gauge to the sensor connector.

- Operate the engine and check the gauge reading.

- Make a comparison of the pressure measured reading with the defined value. If the manual gauge has a normal pressure reading but the dashboard gauges are not giving normal results, then the sensor is faulty.

Resistance measuring with a multimeter

- In this test, remove the sensor electrical connector. Set the meter at resistance (ohms).

- gets resistance over the terminals of the sensor and makes sure the engine is in off condition, after that at idle condition and with high RPM

- If the resistance value changes according to the vehicle’s demand, it means the sensor is working well, and if not, it means the sensor is not working well.

Voltage Testing

- In this test, a multimeter was also used.

- Connect the sensor electrical connector.

- If the engine is running, a multimeter is used for measuring voltage at the sensor connector.

- Make a comparison of the reading with the manual values If faults occur, it means the sensor is faulty.

Air Pressure Test

- Put the sensor in water and use compressed air there. Check for air bubbles; if they appear, that means the means sensor is internally leaking.