A car’s internal combustion engine uses air and fuel for accurate working. The air-fuel ratio required is optimal for continuous combustion and good engine working. In older vehicles, carburetors controlled the air and fuel mixture. After that, the engine control unit used in new vehicles comes with Mass Air Flow (MAF) sensors for measuring airflow.

This post covers details about the MAF sensor, its working, and other parameters.

What is the MAF Sensor

- A mass air flow sensor, or MAF, is used for measuring the mass flow rate of air moving in a fuel injection combustion engine.

- Air mass data is required for the engine control unit for accurate and uniform fuel mass delivery to the engine.

- Density and pressure of air change, and in vehicles, change based on temperature, altitude, and forced induction. so the MAF sensor works well compared to the volumetric flow sensor for measuring intake air quantity in one cylinder.

- The vehicle engine uses two mass airflow sensors, vane meter, and a hot wire meter. This sensor helps the ECU to measure the mass flow rate of intake air.

- The MAF sensor operated with the help of a heated wire. When airflow on this wire makes it cool, that helps the sensor to measure temperature and reduces and converts that information into an electrical signal.

- That signal given to the ECU, and it finds how much fuel the engine requires now.

- Through continuous measurement of airflow, the MAF sensor helps the engine set fuel injection and ignition.

- In this way, vehicles move smoothly in different conditions, like accelerating, idling, and steady-speed driving.

- If the MAF sensor is not working accurately, the ECU will not get the correct data. that affect fuel efficiency, during stalling and driving.

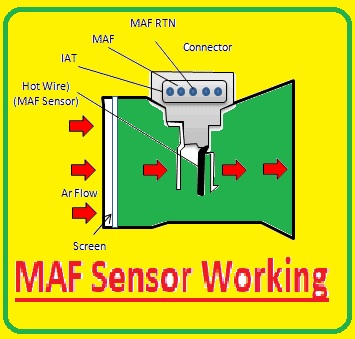

MAF Sensor Working

- The MAF sensor comes with two wires: a hot wire and a thermistor that measures temperature by varying its resistance values.

- It is a hot wire that is heated with current and detects the intake air temperature on the IAT sensor.

- It works with ignition starting; current flows from the battery to the hot wire, which is heated due to the electron flow.

- Wire temperature increases by about three volts. During engine starting, air moves from the filter towards the intake.

- High temperature of the hot wire is released with air flow; when the flow occurs close to the hot wire, it reduces the hot temperature.

- With the reduction in temperature, the current also increases. With idle speed, the current flow is higher than 3 volts in the starting condition, and in the idle condition, five volts.

- high-speed air flow, larger air flow occurs in the machine, and high current is used in the hot wire.

- current transmission to the ECU from the hotwire used for measuring air mass entering into engine

MAF Sensors types

There are different categories of MAF sensors, but each works the same, measuring air coming into the engine that helps to get accurate fuel injection.

Two main types of MAF sensors are explained here.

Hot Wire MAF Sensor

- • The hotwire MAF sensor is a commonly used type. It operated by heating a thin wire at a certain temperature value and measuring the temperature reduction when air flowed over it.

- Moving air removes heat, so cooling is based on air volume coming into the engine.

- To set the temperature of the wire sensor, set the current. For high air flow, the wire becomes cool fast, and the current increases to maintain the temperature.

- Current change transforms into a signal transmitted to the ECU that measures air flow.

- The hot wire sensor has high accuracy and reliability, but its performance is affected due to dust and oil buildup, which causes faulty measurements and reduces engine performance.

- For accurate working, regular cleaning is required.

Read related Oil Pressure Sensor: Features, Working, Uses

Hot Film MAF Sensor

- This type of MAF sensor works like the previous one but uses a thin-film element in place of wire. It sets the temperature and measures the temperature reduction when air flows.

- This sensor comes with different sensing elements that provide accurate readings.

- It comes with a stable design, so it is less affected by contamination and wear than a hot wire sensor.

- But it also needed maintenance for high accuracy

Signs of a bad MAF Sensor

There are different signs of a faulty MAF sensor that affect vehicle’s working. The main function of the MAF sensor is to manage air intake, and with that, the ECU controls the fuel mixture, so any fault affects the working. Some main signs of a faulty MAF sensor are as follows:

Check Engine Light

- The basic symptom of a faulty MAF sensor is the check engine light coming on. The vehicle’s onboard diagnostic system changes in data reading coming from the sensor and shows fault codes according to the faults.

- So if the check engine light comes on, it means the MAF sensor is faulty.

bad acceleration

- When you press the pedal and experience low power for acceleration, there is a fault of the MAF sensor, and it gives error data of airflow to the ECU. That causes the engine to face difficulty for giving the required power, and the vehicle does not get a proper response.

Low Fuel Efficiency

- • A faulty MAF sensor also affects the air-fuel efficiency of the engine, which causes high or low fuel injection. If you frequently need to fill oil without any changes in driving distance on your normal routine, it means your sensor is faulty.

Engine stalling

- If the MAF sensor is faulty, it causes an improper airflow reading, which results in engine stalling. This condition faces RPM changes, engine vibration, and the engine stops working. That is all due to a MAF sensor fault.

Power Loss at High Speeds

- If the vehicle is facing difficulties for constant speed or loses power with high RPM, that is due to a bad MAF sensor that is not measuring airflow at high speed. So for high-speed driving, we face difficulty due to a faulty MAF sensor.

Incorrect Air-Fuel Mixture

- If the MAF sensor is faulty, it detects a faulty reading, causing a high or low fuel mixture for the engine.

- • A low mixture quantity increases engine temperature higher than normal and has a chance of damage with time.

- • A high mixture releases smoke from the exhaust, bad fuel efficiency, and high emissions.

- These different fuel mixtures cause damage.

Testing Method of a MAF Sensor

The testing of the MAF sensor is important for fault detection and finding errors. A commonly used multimeter is used for testing of the MAF sensor.

MAF Sensor location

- First of all, find the MAF sensor that is normally connected in the intake air duct, close to the air filter. For finding location, you can get help from the manual. It is connected with screws and electrical connectors.

visual inspection

- When finding the sensor location, now perform a visual inspection; for this, find visual damage, dust, and loose connections. If you find oil or dust on the sensor, clean it. Also, check that all wiring connections are securely made.

Power supply and ground connection

- Use a multimeter to test that the MAF sensor is getting power and has a ground connection. for this set meter rating at the voltage setting.

- Make a connection between the positive pin of the meter and the sensor power point. negative pin of the meter with ground. Set the ignition key in the ON state without starting the engine.

- If the sensor is not getting the required voltage, it means you have blown fuse wiring

Sensors Voltage

- In engine-off conditions, it separates the connector from the MAF sensor. Now set the meter at the voltage setting. Connect the positive pin with the signal wire terminal and the negative with the ground.

- on ignition without engine starting, and measures the voltage value.

- Make sure the voltage value is in the range of the value mentioned in the manual.

sensor voltage in the idle condition

Read related What is a Throttle Position Sensor: Features, Uses

- Start the engine and make it idle. As the engine is on, measure the voltage with a meter. The voltage value must be in the range of vehicle requirements.

- sensor is faulty in case of high or low voltage

Voltage value at variable RPMs

- Keep the engine on; apply pressure on the accelerator for rpm increasing. Check the reading on the meter. Make sure reading varies smoothly with airflow increases.

- If the voltage has a constant reading, dropping quickly, it means the sensor is not working well.

Contamination cleaning

- If reading is not according to requirements, disconnect the sensor and check for contamination. If dust particles exist, clean them; they affect accuracy.

- Remove dust with a cleaner during cleaning; do not touch sensor components directly.

- If values are not accurate after cleaning, use a new sensor and get service from a professional.

How to Replace a MAF Sensor

- First of all, gather the required tools for replacement, like a socket wrench that connects or disconnects the sensor. Use safety gloves and glasses for protection purposes.

- Now, find the location of the sensor; get help from the vehicle manual for this. normally connected on the intake air duct close to the filter.

- Now disconnect the connector on the sensor. According to the vehicle, you can separate with the release tab or any tool used for disconnection.

- Now using tools to remove screws and clamps to separate the sensor.

- After disconnecting the faulty MAF sensor, connect the new one at the same point. Make sure it is accurately connected without any damage.

- In this step, connect the connector on the new sensor. Ensure it is strongly connected and locked at that point.

- Again, check the connection for loose wires or any broken connections.

- In the last step, start the engine and let it idle for some time. Monitor the engine working and make sure the lights are off. If the engine runs without stopping and there is no light signal, it means the new sensor is working well.

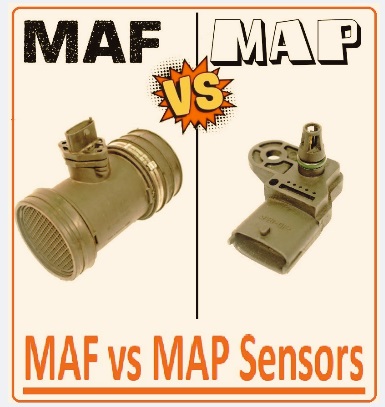

MAF vs MAP Sensors

| Feature | MAP Sensor (Manifold Absolute Pressure) | MAF Sensor (Mass Air Flow) |

| working Principle | it measures the absolute pressures of the intake manifold | used for measuring the mass of air coming into the engine |

Data send to the ECU | engine load according to manifold pressure | mass of incoming air |

Air Temperature Compensation | Not measure air temperature | MAF sensors have temperature sensors |

| Location | intake manifold | In the intake air duct, close the air filter |

| Engine Load | Measure load with manifold pressure | accurate air mass data, indirect for load calculation |

Throttle Changes | fast response to throttle position changes | delay due to the airflow sensor reading |

| Engine Type | good for forced induction engines | used in naturally aspirated engines |

Complexity of Installation | easy installation has low components | it needed accurate placement and calibration accurate working |

Failure Symptoms | bad fuel economy, hesitation, rough idling, and incorrect air-fuel mixture | stalling, poor acceleration, and check engine light |

Replacement Cost | less expensive | expensive due to sensor complexity |

Maintenance Requirements | Low maintenance, | Requires regular cleaning |

Effect of Dirty Air Filter | Less affected | affected |

| Applications | naturally aspirated and forced induction engines | naturally aspirated engines |

Fuel Injection Calculation | Works with the speed-density system airflow | direct airflow calculation for accurate fuel injection |

Performance Optimization | preffered for turbocharged | in engines where accurate air measurement is needed |

| Usage | older or turbocharged vehicles | modern vehicles for better fuel efficiency |

| Sensitivity to Air Leaks | Less affected by vacuum leaks | sensitive to vacuum leaks, which can cause faulty readings |

Some Fault Codes for MAF Sensors

P0100: Air Flow Circuit Malfunction

- This code shows an error with the sensor circuit. That shows sensor wiring has faults. or the engine control not working well. For this error, check the wiring connection and clean the sensor to solve the error. If the error still exists, the sensor needs replacement.

P0101: Circuit Range/Performance Problem

- This code occurs when the MAF sensor data does not according to requirements, causing the code to be thrown through the ECU. It results from a sensor that is damaged or has dust.

- This error also occurs due to a leak or blockage in the air intake system. To solve this error, monitor the air filter and intake ducts for faults.

P0102: MAF circuit low input.

Read related What is a catalytic converter? Features, Working, Uses

- If the MAF sensor voltage reading is less than the required value, this code error occurs. It is due to faulty sensor dust on the sensor or wiring, causing faults.

- If the vehicle is working badly, losing power, clean the sensor. After that, make sure the wiring and connections are securely made.

P0103

- If the MAF sensor produces a higher voltage than the required value, this code is shown. It occurs due to wiring faults, sensors with dust, and damaged sensors. Cleaning the sensor solves these faults; if not, use a new sensor.

P0171

- If the engine is working lean, there are high air exits but less fuel, which shows the code. A faulty sensor gives a different reading that shows an error.

- This code also occurs due to leaking and low fuel pressures. To solve this error, remove leaks and clean the MAF sensor.

P0172

- This code is the reverse of the previous one, meaning more fuel than air. A falling MAF sensor causes faulty air-fuel mixture calculations, which cause bad fuel efficiency and high emissions. Other causes are leaking fuel injectors. This error can be solved through sensor cleaning and checking fuel system parts.

CONCLUSIONS

The mass air flow sensor is an important component for the working of an internal combustion engine. According to its airflow values, the ECU makes the required air and fuel mixture. It is an important component; without that, our vehicle will not work. Its proper working and maintenance are needed for accurate working. Its replacement is also low-cost and can be cleaned easily.