Injection and casting molding are two manufacturing processes that help make different products and manufacturing processes. Polyurethane is used for making objects like vehicle gaskets, casters, settings, medical carts, and some other parts. In this post, we will cover the detailed features of injection molding, casting, and urethane casting to find their differences. So let’s get started

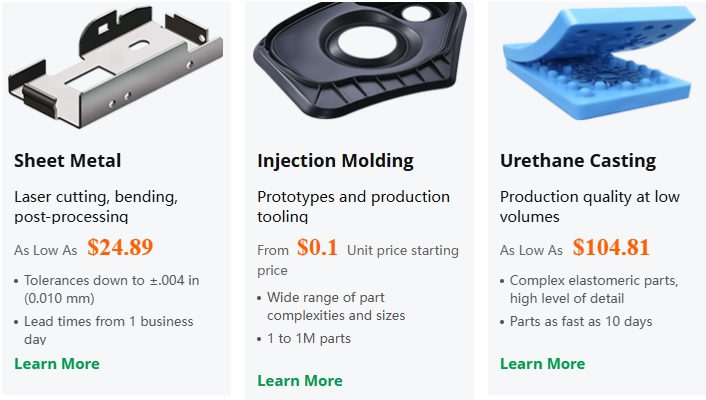

Sheet Metal vs Injection Molding: service

Sheet metal and injection molding are now important parts of the manufacturing industry that need quality tools and skilled manufacturers to perform these services. JUSTWAY manufacturer is a high-level skilled supplier that not only provides 3D printing services but also offers services for injection molding, sheet metal, and related services.

For just $24.89, you can get sheet metal service with features like laser cutting, bending, and post-processing with a lead time of business days.

Injection molding comes with prototyping and production tools for 0.1 dollars for a single unit, and you can get a larger range of parts and complications.

urethane casting we can get for $104.81.

Injection molding finishes the details.

| Glossy | Semi-Glossy | Matte | Textured |

| SPI-A2 | ±0.1mm | ±0.05mm | MT (Moldtech) |

| SPI-B1 | SPI-B2 | ±0.1mm | VDI (Verein Deutscher Ingenieure) |

| SPI-B3 | ±0.2mm | YS (Yick Sang) |

sheet metal fabrication processes are as

| Name | Description | sheet thickness |

| Laser cutting | uses a high-power laser beam to cut a material sheet. | This process employed a high-power laser beam to cut a material sheet. |

| Bending | uses dies to produce a U-shape, V-shape or channel shape along a straight axis in ductile materials. | 1-6mm |

Materials for urethane casting are as

| Plastic | |||

| ABS | POM | Nylon | Polycarbonate (PC) |

| PC/ABS | PVC | Polyethylene (PE) | Polypropylene (PP) |

| Polystyrene (PS) | TPU | Rubber |

Difference Between Injection Molding and Vacuum Casting

Basic difference between injection molding and vacuum casting areas

Volume

- Injection molding has a high starting cost since it is used for making durable, metallic molds. But this initial cost is covered through per-unit volume for bulk productions, and so it is preferred for bulk manufacturing processes.

- while vacuum casting operates with low-cost silicone molds, which is high-speed and low cost to manufacture. but it is low durability; it can manage about 20 to 30 parts before replacement.

- So vacuum casting is a low-cost option for small to bulk productions.

Speed and Setup:

- Vacuum casting has a speedy setup, so it is part of rapid prototyping and small productions where time is the main factor.

- This process uses simple and fast mold preparation that minimizes the time from designing to final assembly.

- while injection molding takes longer mold manufacturing time and has a high starting setup cost. But while working, it operates for high-speed productions that have a higher rate than vacuum casting.

Material

- Injection molding can operate for different materials, such as elastomers and thermoplastics, that provide high flexibility for material features like heat resistance, strength, and durability.

- This larger material option is important for different applications that operate in certain conditions.

- While vacuum casting uses only polyurethane resins, which is low-cost as compared to materials used in injection molding, it provides different material looks and structures for a broader range of materials.

Precision

- Injection molding is a highly accurate process since it uses metal molds that are made for fulfill the features of tolerance.

- This method is used for complicated designs and complex structures that require a high level of accuracy.

- Vacuum casting has features of high-quality parts manufacturing with clear details, so it is used for complicated products and also provides good dimensional accuracy.

What is Vacuum Casting?

- Vacuum casting is a process used for making different parts with the help of adding liquid plastic in a mold with the existence of a vacuum.

- The mold is made with soft natural materials like silicon. Molds come with liquid plastic; after that, place them in the oven for heating and curing.

- Not all plastics need heating for curing. Some materials easily cure at room temperature. After curing, the mold opens, and the cast parts get.

- For small productions, finished plastic parts are made with the use of vacuum casting. It is also used for rapid prototyping of products that are last injection molded.

- master pattern used for making soft molds with the use of vacuum casting.

- master model SNC machine-based module of cast part. master pattern; after that, put in liquid silicone that cures and sets.

- After setting, the master pattern is cut in half, and the part and the CNC machine part are separated.

- In this way we get two parts of the mold that are like the casting part.

What is Injection Molding?

- The injection molding process is employed for bulk volume productions that need a high level of accuracy.

- In this process, molten material is put in high-pressure conditions and converted into metallic molds, like steel or aluminum.

- With this process, high accuracy with low variations is needed, and is good for bulk manufacturing of the same objects.

- Either molding is a high-cost process, but has a longer working life and makes a low cost per unit for bulk production volumes.

- Injection molding manages a larger material spectrum, which makes this process effective for applications where different mechanical features are needed, like high strength and resistance to different chemicals

How Injection Molding Works

- First of all, the mold is put into an injection molding machine, where the mold closes in the machine through clamp applications, and the mold is closed when plastic injection molding is performed.

- Place plastic in granule shape into the injection molding machine.

- Injection molding machines apply heat to plastic till it is converted into a liquid.

- injection molding machine, the nozzle adds molten plastic into the mold. where the mold cavity has plastic liquid. This liquid is the result of solid products after cooling.

- In the last ejector release, cooled materials are produced through the machine when the part is completed.

Advantages of Vacuum Casting

- Vacuum casting is a low-cost option for small-scale projects since its tools are low-cost. It is good for low-volume manufacturing processes where larger costs for metal molds are not needed.

- This process needs a short mold setup and less production time for delivery as compared to injection molding. It’s low-time-consuming due to the silicon molds as compared to the time-consuming metallic molds that are part of injection molding.

- Vacuum casting is used for high design where flexibility is needed. It makes complex designs that are difficult to make through injection molding. This flexible design is used at the prototyping level, where design changes can be made.

- As compared to injection molding, vacuum casting is low-cost for prototypes and low-volume production, whereas injection molding is used for high-volume production. So vacuum casting is preferred where low-volume productions are needed.

Disadvantages of Vacuum Casting

- It uses fewer materials; options like polyurethane resins do not have the high strength of materials used in injection molding like ABS, polypropylene, and polycarbonate.

- Vacuum casting uses silicon molds that work for about 30 parts and need replacement. that affect the overall cost and are used for bulk projects

- Either vacuum casting is preferred for some applications, but it is not as accurate as injection molding. That is not preferred for complicated designs.

- Parts made with vacuum casting are lower in strength than those made with injection molding. Since of the features of resins are less robust as compared to thermoplastics used in injection molding.

Advantages of Injection Molding

- Injection molding is used for complicated designs and provides higher accuracy than vacuum casting. It also provides high tolerance and consistency for many parts.

- It also supported high-volume productions with efficiency and speed, which reduces unit cost compared to vacuum casting.

- Durable materials like steel and aluminum are used for making injection molding that manages the pressure of making thousands of parts without damage.

- Injection molding has access for different material applications, like elastomers and engineering plastics. that comes with larger features for final assembly, and also added rigid and flexible design and heat resistance features

Disadvantages of Injection Molding

- It has higher starting costs for tools and injection molding than vacuum casting, so it is a low-cost option for small productions.

- Designing and manufacturing molds in injection molding is a time-consuming process that takes many months. That is a limitation for projects where rapid product development is needed.

- Injection molding is not preferred for small operations since there are high costs related to mold preparation. That is best for prototypes or small batches where vacuum casting can be a flexible and low-cost option.

When to Choose Vacuum Casting

- Vacuum casting is a low-cost option for manufacturing small-volume productions, like 100 units. That is perfect where larger-scale production is not required.

- Vacuum casting uses low-cost tools, which have a lower starting cost than injection molding.

- Its flexible nature helps to make rapid prototyping and testing of different designs, and it can change without the use of high-cost mold adjustments.

- Vacuum casting offers a quality surface finish and is used for designs where high complications are not needed.

When to Choose Injection Molding

- Injection molding is preferred for bulk production, where thousands to tens of thousands of parts are made at a low cost for a single unit.

- Materials used for injection molding are high-quality thermoplastics and have better strength and more durable features than resin that is used for vacuum casting.

- Injection molding helps to make complicated designs with higher accuracy and tolerance than vacuum casting.

- we can employ a different range of materials that help to make quality features for materials like elasticity to resistance.