You have a brilliant idea for an automation project—whether it’s a home brewing system that keeps fermentation conditions perfect or a full-scale factory assembly line that must run reliably for years.

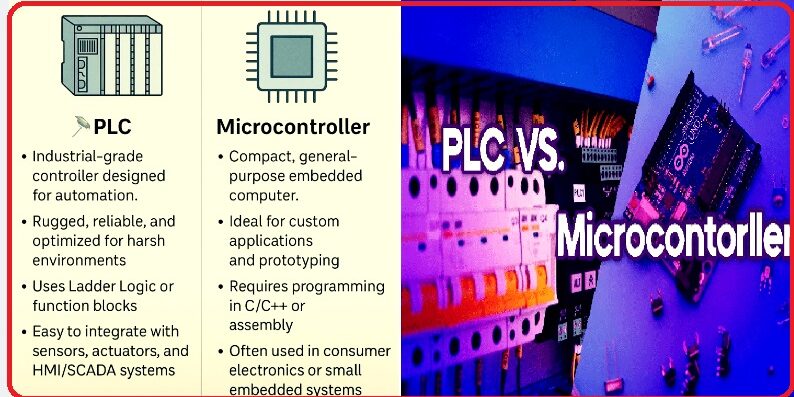

This idea works in making important decisions. What hardware will act as the brain of the system? One is Programmable Logic Controllers (PLCs), an important tool of industry; another is a microcontroller, a compact design that is low cost and used to make prototypes and consumer products.

In this post, we will cover the difference between PLCs and microcontrollers across environment, programming, and cost and find their engineering project applications.

What is a PLC: an industrial powerhouse?

- The PLC, or programmable logic controller, is the main part of the industry used for different process control, machine automation, and different machine controls in the industry.

- PLC is a replacement of hard-wired relay logic with programmable logic and flexible design and easily handles heat, electrical noise, vibrations, and dust on the factory floor.

- It has features for compact brick units with built-in input to output for larger rack-mounted systems that have hundreds or thousands of distributed I/O points.

Features of PLCs

simple design:

- PLC made for handling different temperature ranges, controlling electrical interference, and also regulating humidity and vibrations, and testing different industrial deployments.

Modular I/O:

- PLC provides a modular analog and discrete input/output module that can be added or swapped without affecting CPU design. That makes scaling and field wiring configuration easy for medium-to-large installations.

Programming environment:

- ladder diagram common language for electricians and technicians since it comes from relay logic schematics. PLC is compatible with IEC 61131-3 languages such as Function Block Diagram (FBD) and Structured Text (ST), which helps to provide good textual or block-based features according to demand.

High reliability & safety:

- PLCs provide 24/7 operation, like watchdogs, and diagnostics and are used for safety purposes and continuous uptime as required. Different PLC platforms and modules come with features for fulfilling industrial safety standards and certifications.

What is a microcontroller?

- A microcontroller is a compact integrated circuit that comes with a CPU core, memory, and programmable input/output devices in one chip.

- A microcontroller is a computer on a chip that is employed for embedded systems like sensor nodes and user devices for high-performance IoT devices.

- Different development boards, like Arduino, ESP32-based boards, and STM32 dev boards, make them accessible for prototyping and small-volume products.

Features of microcontrollers

Flexibility

- • The microcontroller is black slate, where we design circuits and programs for handling features in hardware limits.

- These features are good for custom sensors, novel products, and research prototypes.

Programming languages and ecosystems:

- The microcontroller gets programming through C/C++ and, increasingly for some boards, Python variants such as MicroPython.

- The design of libraries, drivers, and the community makes the development of the board, like for networking, ML inference on edge devices, and custom protocols.

Low cost:

- Development boards and modules are low-cost, like a few dollars to around $50 for higher-end dev boards, which lowers the barrier to experimentation and rapid iteration.

Environment and hardening:

- MCU has benign, environment-controlled features for use in industries, engineering design, filtering, transient protection, and certified power supplies, which are typically required.

PLC vs. Microcontroller

Here are the factors explained for finding the importance of PLC and MCU for certain projects. Here we have mentioned different points for finding the difference.

Operating environment

PLC:

- PLCs work well for harsh conditions used in industries. It has a strong enclosure, power conditions, and input/output isolation built for factory conditions.

Microcontroller:

- It works well for controlled conditions and clean environments until we have substantial hardening and certification.

Programming & development times

PLC:

- Ladder logic helps us to control and apply and troubleshoot control sequences easily, like in discrete I/O and safety interlocks.

- For simple control tasks, PLC development can be fast.

Microcontroller:

- If you are working on a project that needs complicated design, data processing, web services, or ML inference, MCUs are good for high flexibility.

- But development time increases if custom hardware design, driver development, or embedded software is required.

Cost and availability

PLC:

- High hardware costs up front: PLC CPU, rack modules, and certified input and output cause it to run with some hundred to thousands of dollars.

- For industrial projects, net ownership costs less due to PLC reducing engineering time and easy maintenance, and it also has vendor support.

- Sourcing PLCs is also easy through specialized distributors. For example, you can browse Iainventory’s extensive range of PLCs to see options from major brands and used/surplus models that simplify procurement for professional projects.

Microcontroller:

- It has low hardware cost for dev boards and modules, which makes it good for prototypes and consumer products. For moving to manufacturing, net charges increase for custom PCB design, certification charges, and transient protection.

Reliability and uptime

PLC:

- It is engineered and tested for longer life, comes with a scan cycle, and has failure modes that are tolerable, making it good for mission-critical processes.

Microcontroller:

- It relies on features based on design, firmware simplicity, supply, and EMI protection. The properly designed MCU system is reliable and needs proper engineering to fulfill PLC-class uptime.

Why Choose a PLC?

- if your project is applied to an industrial plant and faces harsh conditions

- There is a need for strong uptime and easy maintenance through electricians or automation technicians.

- There is use of standard input/output, certified modules, and collaboration with industry systems like Profibus, EtherNet/IP, Profinet, etc.

- Long-term support, diagnostics, and safety certification are priorities.

Why Choose a Microcontroller?

- Use MCU for one of the sensor nodes, prototypes, consumer products, or projects that use the latest local processing, networking, or ML capabilities?

- It cost the primary driver and module to live in a controlled environment.

- Use for fine-grained control over hardware resources and needed to find a large open-source ecosystem.

Microcontroller vs. PLC: Comprehensive Comparison Table

| Feature | Microcontroller | PLC (Programmable Logic Controller) |

| Cost | Lower upfront cost | Higher initial cost |

| Complexity | used for simple to middle-level operations

| good for complex industrial processes |

| Programming Languages | C, C++, Python, Assembly | Ladder Logic, Function Block Diagram (FBD), graphical interfaces |

| Programming Flexibility | High | Medium |

| Ease of Programming | coding skills needed | Easy through use of graphical interfaces |

| Industrial Reliability | depends on housing and environment | High (good for harsh industrial environments) |

| Operating Environment | Limited, protection against dust, vibration, temperature | High tolerance |

| Maintenance | require technical expertise | Simple, modular replacement |

| I/O Expansion | Limited; custom circuits or shields required | Easy, modular with standard expansion modules |

| Scalability | complex | Easily scalable with plug-and-play modules |

| Integration with Motedis Components | Excellent for dynamic accessories; | Plug-and-play with an industrial tool like aluminum profiles |

| Integration with Factory Equipment | needed customization | good for out-of-the-box integration |

| Applications | Custom machines, prototypes, embedded systems | Industrial automation, process control |

| Clock Speed (Typical) | 16 MHz to120 MHz | lower, optimized for control tasks |

| Memory (Flash / RAM) | 32 KB – 2 MB / 2 KB – 256 KB | Generally, higher memory and backup systems |

| Input/Output Pins | 10 to 100+ | based on model; easily expandable |

| Operating Voltage | 3.3V / 5V | 24V typical in industrial settings |

| Communication Interfaces | UART, SPI, I2C, CAN | Modbus, Ethernet/IP, Profibus, CAN |

| Flexibility | Highly customizable for specific operations | Highly adaptable and modular for industrial systems |

| Industrial Robustness | Medium | High |

Conclusion

PLCs and microcontrollers are both powerful tools but are used for different engineering operations. PLC is made for standard I/O and safety for industrial use. MCU has a flexible design, low cost, and a larger software system that helps to find innovation and rapid prototyping.

The main usage is based on the environment, requirements, development resources, and maintenance for the project.

So the answer is not which is better, but which tool can be used for a certain project. Use tools and software according to working conditions, performance, safety measures, and the project’s working life.