Wrenches come with both standard wrench sizes and metric wrench sizes that are important for mechanics, and each is made for certain uses. The knowledge of wrench size charts with metric and standard details is important for performing different operations. It helps to make vehicle repairs or industry maintenance.

With knowledge of this charge, we can find different faults and errors for using faulty wrenches or socket sizes that can cause damage to instruments. In this post we will cover details of features for finding standard wrench sizes charts.

Introduction to Wrenches

- The wrench, also called a spanner, is a tool that is used for providing a strong grip and mechanical features for applications of torque for turning different objects, like rotary fasteners like nuts and bolts.

- In different countries like New Zealand, Ireland, and the UK, it is commonly known as a spanner. Based on shape, it is called an open-ended spanner and a ring spanner.

- The wrench word is used for tools that turn non-fastening devices, also called monkey wrenches.

- The wrenches are made with the use of high-quality chromium vanadium alloy tool steels and are drop forged. It is chrome-plated for corrosion resistance and to provide easy cleaning.

Different Types of Wrenches

Read also Socket Size Chart – Socket Sizes in Order from Smallest to Largest

- There are different wrench types that come with different features and uses. Some types are made for standard fastener operations, and some are made to be used for metric applications.

- Color-coded wrenches for standard and metric, and different types of wrenches are explained here.

Adjustable Wrenches

- Adjustable wrenches are durable and come with a longer working life. This wrench helps to set the width of the wrench when there is not known accurate size of nut. It is also used for standard and metric parameters. So there is no need to get a complete wrench in the toolbox since an adjustable wrench is used for different bolt sizes.

Open-Ended Wrenches

- It comes with the same design as an adjustable wrench and comes in fixed sizes. Open-ended wrenches are double-sided wrenches that have different wrench sizes for each end. Use an accurate size of open-ended wrench since it comes with the same size of nut for accurate fitting of the nut. It provides a stronger grip than other wrenches and also has a thin size that is used for closed spaces.

Box-Ended Wrench

- The box-ended wrenches are like open-ended wrenches and have a box-like design. Its main feature is that it fits on a nut easily and gets high power leverage.

- It is difficult to use since the wrench is for closed spaces.

Combination Wrench

- The combination wrench is an open-ended wrench and a box-ended wrench. It provides more than one feature. The combination wrench comes with features for fitting into closed spaces like an open-end wrench and gives high power that box-end wrenches provide. The closed end is good to use for loosening a strongly closed nut. It also removes nuts fast.

Pipe Wrench

- This wrench provides a strong grip for pipes. The slack of the pipe wrench used for pipe fitting and the pipe can latch due to angled teeth.

- When we use a wrench in the reverse direction, the wrench moves to lock on the pipe.

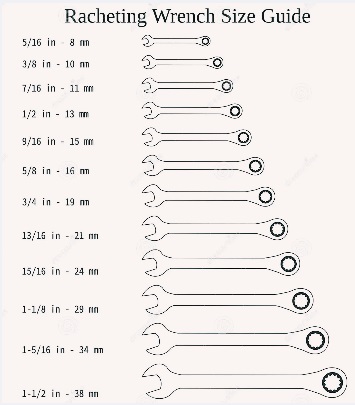

Ratchet Wrenches

- It is used for tightening or loosening nuts and bolts. So it is good for metric and standard sizes. It is easy to handle since it has a thin size. Ratchet is also used for closed spaces.

Standard wrench sizes in order

Read also Wire Ampacity Charts | Wire Gauge Chart

- Standard USA wrench sizes from largest to smallest in inches are 5/8, 19/32, 9/16, 1/2, 7/16, 3/8, 11/32, 5/16, 9/32, 1/4, 7/32, 3/16, 5/32, and 1/8.

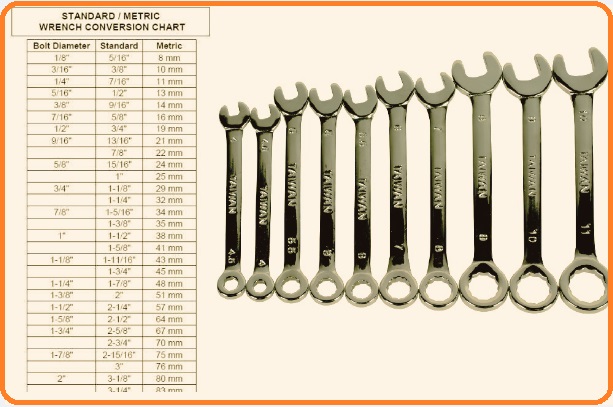

- Here we have made a chart for standard and metric wrench charts. with that list of standard tools size chart explained.

| Bolt Diameter | Metric or wrench size chart in mm | Standard |

| 1/8″ | 8mm | 5/16″ |

| 3/16″ | 10mm | 3/8″ |

| 1/4″ | 11mm | 7/16″ |

| 5/16″ | 13mm | 1/2″ |

| 3/8″ | 14mm | 9/16″ |

| 7/16″ | 16mm | 5/8″ |

| 1/2″ | 19mm | 3/4″ |

| 9/16″ | 21mm | 13/16″ |

| 22mm | 7/8″ | |

| 5/8″ | 24mm | 15/16″ |

| 25mm | 1″ | |

| 3/4″ | 29mm | 1-1/8″ |

| 32mm | 1-1/4″ | |

| 7/8″ | 34mm | 1-5/16″ |

| 35mm | 1-3/8″ | |

| 1″ | 38 mm | 1-1/2″ |

| 41mm | 1-5/8″ | |

| 1-1/8″ | 43mm | 1-11/16″ |

| 45mm | 1-3/4″ | |

| 1-1/4″ | 48mm | 1-7/8″ |

| 1-3/8″ | 51mm | 2″ |

| 1-1/2″ | 57mm | 2-1/4″ |

| 1-5/8″ | 64mm | 2-1/2″ |

| 1-3/4″ | 67mm | 2-5/8″ |

| 70mm | 2-3/4″ | |

| 1-7/8″ | 75mm | 2-15/16″ |

| 76mm | 3″ | |

| 2″ | 80mm | 3-1/8″ |

| 83mm | 3-1/4″ | |

| 2-1/4″ | 89mm | 3-1/2″ |

| 95mm | 3-3/4″ | |

| 2-1/2″ | 99mm | 3-7/8″ |

| 102mm | 4″ | |

| 2-3/4″ | 108mm | 4-1/4″ |

| 114mm | 4-1/2″ | |

| 3″ | 118mm | 4-5/8″ |

| 3-1/4″ | 127mm | 5″ |

| 3-1/2″ | 137mm | 5-3/8″ |

| 140mm | 5-1/2″ | |

| 3-3/4″ | 146mm | 5-3/4″ |

| 152mm | 6″ | |

| 165mm | 6-1/2″ | |

| 178mm | 7″ |

Wrench size larger Than 3/4

| Bolt Diameter | Standard Wrench Size | Metric Wrench Size |

| 1/8″ | 5/16″ | 8mm |

| 3/16″ | 3/8″ | 10mm |

| 1/4″ | 7/16″ | 11mm |

| 5/16″ | 1/2″ | 13mm |

| 3/8″ | 9/16″ | 15mm |

| 7/16″ | 5/8″ | 16mm |

| 1/2″ | 3/4″ | 19mm |

| 9/16″ | 13/16″ | 21mm |

| 5/8″ | 15/16″ | 24mm |

| 3/4″ | 1-1/8″ | 29mm |

| 7/8″ | 1-5/16″ | 34mm |

| 1″ | 1-1/2″ | 38mm |

| 1-1/8″ | 1-11/16″ | 43mm |

| 1-1/4″ | 1-7/8″ | 48mm |

| 1-3/8″ | 2-1/16″ | 53mm |

| 1-1/2″ | 2-1/4″ | 58mm |

| 1-5/8″ | 2-7/16″ | 62mm |

| 1-3/4″ | 2-5/8″ | 67mm |

| 1-7/8″ | 2-13/16″ | 72mm |

| 2″ | 3″ | 77mm |

| 2-1/4″ | 3-3/8″ | 86mm |

| 2-1/2″ | 3-3/4″ | 96mm |

| 2-3/4″ | 4-1/8″ | 105mm |

| 3″ | 4-1/2″ | 115mm |

Standard Socket Sizes Chart

| 1/4″ Drive | 3/8″ Drive | 1/2″ Drive | 3/4″ Drive | 1″ Drive |

| 5/32″ | 1/4″ | 3/8″ | 7/8″ | 1-5/8″ |

| 3/16″ | 5/16″ | 7/16″ | 15/16″ | 1-11/16″ |

| 7/32″ | 3/8″ | 1/2″ | 1″ | 1-3/4″ |

| 1/4″ | 7/16″ | 9/16″ | 1-1/16″ | 1-13/16″ |

| 9/32″ | 1/2″ | 19/32″ | 1-1/8″ | 1-7/8″ |

| 5/16″ | 9/16″ | 5/8″ | 1-3/16″ | 2″ |

| 11/32″ | 5/8″ | 21/32″ | 1-1/4″ | 2-1/8″ |

| 3/8″ | 11/16″ | 11/16″ | 1-5/16″ | 2-3/16″ |

| 7/16″ | 3/4″ | 3/4″ | 1-3/8″ | 2-1/4″ |

| 1/2″ | 13/16″ | 25/32″ | 1-7/16″ | 2-3/8″ |

| 9/16″ | 7/8″ | 13/16″ | 1-1/2″ | 2-1/2″ |

| 15/16″ | 7/8″ | 1-5/8″ | 2-5/8″ | |

| 1″ | 15/16″ | 1-11/16″ | 2-3/4″ | |

| 1″ | 1-3/4″ | 2-15/16″ | ||

| 1-1/16″ | 1-13/16″ | 3″ | ||

| 1-1/8″ | 1-7/8″ | 3-1/8″ | ||

| 1-3/16″ | 2″ | |||

| 1-1/4″ | 2-1/8″ | |||

| 1-1/2″ | 2-3/16″ | |||

| 2-1/4″ |

Standard-to-Metric Conversion Chart

| SAE Sizes | Metric Sizes | Similar Socket Sizes |

| 5/32″ | 4mm | 5/32″ and 4mm are almost the same |

| 4.5mm | ||

| 3/16″ | ||

| 5mm | ||

| 5.5mm | ||

| 7/32″ | ||

| 6mm | ||

| 1/4″ | ||

| 6.5mm | ||

| 7mm | ||

| 9/32″ | ||

| 5/16″ | 5/16″ and 8mm are almost the same | |

| 8mm | ||

| 11/32″ | ||

| 9mm | ||

| 3/8″ | ||

| 10mm | ||

| 13/32″ | ||

| 11mm | 7/16″ and 11mm are almost the same | |

| 7/16″ | ||

| 15/32″ | 15/32″ and 12mm are almost the same | |

| 12mm | ||

| 1/2″ | ||

| 13mm | ||

| 17/32″ | ||

| 14mm | ||

| 9/16″ | ||

| 15mm | 19/32″ and 15mm are almost the same | |

| 19/32″ | ||

| 5/8″ | ||

| 16mm | ||

| 21/32″ | ||

| 17mm | ||

| 11/16″ | ||

| 18mm | ||

| 23/32″ | 19mm | 3/4″ and 19mm are almost the same |

| 3/4″ | ||

| 25/32″ | ||

| 20mm | ||

| 13/16″ | ||

| 21mm | ||

| 27/32″ | ||

| 22mm | ||

| 7/8″ | ||

| 23mm | 29/32″ and 23mm are almost the same | |

| 29/32″ | ||

| 15/16″ | ||

| 24mm |

Imperial Wrench Sizes (inches)

| Wrench Size (inches) | Use |

| 1/4″ | 1/16″ |

| 5/16″ | 3/16″ |

| 3/8″ | 1/4″ |

| 7/16″ | 5/16″ |

| 1/2″ | 3/8″ |

| 9/16″ | 7/16″ |

| 5/8″ | 1/2″ |

| 11/16″ | 9/16″ |

| 3/4″ | 5/8″ |

| 13/16″ | 11/16″ |

| 7/8″ | 3/4″ |

| 15/16″ | 7/8″ |

| 1″ | 7/8″ |

| 1 1/16″ | 1″ |

| 1 1/8″ | 1″ |

| 1 1/4″ | 1 1/8″ |

| 1 5/16″ | 1 1/8″ |

| 1 3/8″ | 1 1/4″ |

| 1 7/16″ | 1 1/4″ |

| 1 1/2″ | 1 3/8″ |

Wrench Conversion Chart – Metric to Standard

| METRIC SIZE (MM) | CLOSEST STANDARD SIZE | DECIMAL EQUIVALENT | DIFFERENCE |

|---|---|---|---|

| 3.18mm | 1/8″ | 0.125″ | +0.000″ |

| 4mm | 5/32″ | 0.156″ | -0.001″ |

| 5mm | 3/16″ | 0.188″ | -0.009″ |

| 6mm | 7/32″ | 0.219″ | -0.017″ |

| 7mm | 1/4″ | 0.250″ | -0.025″ |

| 8mm | 5/16″ | 0.313″ | -0.002″ |

| 9mm | 11/32″ | 0.344″ | -0.010″ |

| 10mm | 3/8″ | 0.375″ | -0.019″ |

| 11mm | 7/16″ | 0.438″ | -0.005″ |

| 12mm | 15/32″ | 0.469″ | +0.003″ |

| 13mm | 1/2″ | 0.500″ | -0.012″ |

| 14mm | 9/16″ | 0.563″ | -0.012″ |

| 15mm | 19/32″ | 0.594″ | +0.003″ |

| 16mm | 5/8″ | 0.625″ | -0.005″ |

| 17mm | 21/32″ | 0.656″ | +0.013″ |

| 18mm | 11/16″ | 0.688″ | +0.021″ |

| 19mm | 3/4″ | 0.750″ | -0.002″ |

| 20mm | 25/32″ | 0.781″ | +0.006″ |

| 21mm | 13/16″ | 0.813″ | +0.014″ |

| 22mm | 7/8″ | 0.875″ | -0.009″ |

| 23mm | 29/32″ | 0.906″ | -0.000″ |

| 24mm | 15/16″ | 0.938″ | -0.007″ |

| 25mm | 1″ | 1.000″ | -0.016″ |

| 26mm | 1-1/32″ | 1.031″ | -0.007″ |

| 27mm | 1-1/16″ | 1.063″ | +0.001″ |

| 28mm | 1-1/8″ | 1.125″ | +0.023″ |

| 29mm | 1-5/32″ | 1.156″ | +0.014″ |

| 30mm | 1-3/16″ | 1.188″ | +0.006″ |

| 31mm | 1-7/32″ | 1.219″ | -0.002″ |

| 32mm | 1-1/4″ | 1.250″ | -0.010″ |

| 33mm | 1-19/64″ | 1.297″ | -0.002″ |

| 34mm | 1-5/16″ | 1.313″ | -0.026″ |

| 35mm | 1-3/8″ | 1.375″ | +0.003″ |

| 36mm | 1-7/16″ | 1.438″ | +0.020″ |

| 38mm | 1-1/2″ | 1.500″ | +0.004″ |

| 39mm | 1-9/16″ | 1.563″ | +0.027″ |

| 40mm | 1-9/16″ | 1.563″ | -0.012″ |

| 41mm | 1-5/8″ | 1.625″ | +0.011″ |

| 46mm | 1-13/16″ | 1.813″ | +0.001″ |

| 50mm | 2″ | 2.000″ | +0.032″ |

| 51mm | 2″ | 2.000″ | -0.008″ |

| 54mm | 2-1/8″ | 2.125″ | +0.000″ |

| 55mm | 2-5/32″ | 2.156″ | -0.009″ |

| 57mm | 2-1/4″ | 2.250″ | +0.006″ |

| 58mm | 2-9/32″ | 2.281″ | +0.000″ |

| 60mm | 2-3/8″ | 2.375″ | +0.014″ |

| 63mm | 2-1/2″ | 2.500″ | +0.020″ |

Torque Wrench Drive Size

Torque wrenches are according to the same drive size as regular ratchets, but they are accurate tools made for certain torque ranges. Some accurate torque wrenches drive size according to SAE socket sizes are

SAE Socket Size Range | Torque Wrench Drive Size | Common Torque Range |

| 1/4″ to 3/8″ | 1/4″ Drive | 20–200 in-lb (inch-pounds) |

| 3/8″ to 5/8″ | 3/8″ Drive | 10–80 ft-lb |

| 5/8″ to 7/8″ | 1/2″ Drive | 30–250 ft-lb |

| 7/8″ and larger | 3/4″ or 1″ Drive | 100–600+ ft-lb |

Standard wrench sizes over 1 inch

Wrench Size (inches) | Decimal |

| 1-1/16″ | 1.0625 |

| 1-1/8″ | 1.125 |

| 1-3/16″ | 1.1875 |

| 1-1/4″ | 1.25 |

| 1-5/16″ | 1.3125 |

| 1-3/8″ | 1.375 |

| 1-7/16″ | 1.4375 |

| 1-1/2″ | 1.5 |

| 1-9/16″ | 1.5625 |

| 1-5/8″ | 1.625 |

| 1-11/16″ | 1.6875 |

| 1-3/4″ | 1.75 |

| 1-13/16″ | 1.8125 |

| 1-7/8″ | 1.875 |

| 1-15/16″ | 1.9375 |

| 2″ | 2 |

Wrench size chart metric and standard

| SAE (Inch) | Decimal (in) | Closest Metric (mm) |

| 1/4″ | 0.25 | 6 mm |

| 5/16″ | 0.313 | 8 mm |

| 3/8″ | 0.375 | 10 mm |

| 7/16″ | 0.438 | 11 mm |

| 1/2″ | 0.5 | 13 mm |

| 9/16″ | 0.563 | 14 mm |

| 5/8″ | 0.625 | 16 mm |

| 11/16″ | 0.688 | 17 mm |

| 3/4″ | 0.75 | 19 mm |

| 13/16″ | 0.813 | 21 mm |

| 7/8″ | 0.875 | 22 mm |

| 15/16″ | 0.938 | 24 mm |

| 1″ | 1 | 25 mm |

| 1-1/16″ | 1.063 | 27 mm |

| 1-1/8″ | 1.125 | 29 mm |

| 1-3/16″ | 1.188 | 30 mm |

| 1-1/4″ | 1.25 | 32 mm |

| 1-5/16″ | 1.313 | 33 mm |

| 1-3/8″ | 1.375 | 35 mm |

| 1-7/16″ | 1.438 | 36 mm |

| 1-1/2″ | 1.5 | 38 mm |

| 1-9/16″ | 1.563 | 40 mm |

| 1-5/8″ | 1.625 | 41 mm |

| 1-11/16″ | 1.688 | 43 mm |

| 1-3/4″ | 1.75 | 44 mm |

| 1-7/8″ | 1.875 | 48 mm |

| 2″ | 2 | 50 mm |

(FAQs)

What is the difference between SAE and Metric wrench sizes?

- SAE standard for the Society of Automotive Engineers wrench sizes, calculated for inches and used mostly for vehicles. While metric size is measured in mm and is used all over the world

Is it possible to use a metric wrench on an SAE bolt?

- In some conditions, we can use them, since metric and SAE are close to each other, such as a 13 mm wrench being close to 1/2″ SAE. But it is not recommended to always use the best; it is best to use an accurate size match.

How to convert SAE sizes to metric?

- Use the above-mentioned table, where one inch is 25.4 mm; for this, divide the SAE size by one and take the product with 25.4 for the metric equivalent.

What are the most common wrench sizes?

- • 7/16″, 1/2″, 9/16″, 5/8″, and 3/4″ are common SAE sizes, and the common metric sizes are 10 mm, 13 mm, 15 mm, 17 mm, and 19 mm.

What type of wrench is used for tight spaces?

- The socket wrench comes with a swivel or ratchet box wrench that operates well for tight spaces. It provides flexible working.