CNC machining and 3D printing are part of the manufacturing system; these two processes have now become the main tools for industries and are considered the backbone of the manufacturing process. In this post, we will cover details for 3D printing and CNC machining, and find which one can be used for what. We with also know about the best 3D printing and CNC machining services, and provide details. So let’s get started.

What is CNC machining?

- CNC machining full form, is computer numerical control machining which is a subtractive manufacturing process performed with the use of cutting tools that operate with computer-based control.

- By using these tools, CNC machines make accurate parts through cutting materials from blank material.

- The CNC machining process is accurate and provides high tolerance for bulk production and prototypes.

CNC Machining Works

- There are different steps involved in CNC machining. First of all, a design is made, and then the final assembly is made according to the design.

- In this process, first of all, 2D or 3D model-required projects are made with the help of computer-aided design software.

- That file is transformed into an input given with the help of computer-aided manufacturing software, where the model is converted into machine commands called G-code.

- The G-code given to the CNC machine, according to cutting tools, removes materials from the blank.

- CNC machines can easily operate on different axes, like 3D, 4D, or 5D, for making complicated designs at high accuracy.

- In this process, stepper or servo motors are used for controlling axes that provide accurate cutting and required movement.

What is 3D printing?

- 3D printing, also known as additive manufacturing, is a process that creates 3D objects using digital files.

- The additive process is used for making 3D printed objects; for the additive process, objects are created by making many material layers until final assembly.

- Each layer is a thin cross-section object in layer form. The other name of this process is volumetric 3D printing.

- With the help of this process complete design was made one time without using a layer-by-layer manufacturing process.

- The 3D printing process is the reverse of subtractive manufacturing, which cuts a block of material using a milling machine.

- By using 3D printing, we can easily make complicated designs using a lower material quantity than conventional manufacturing processes.

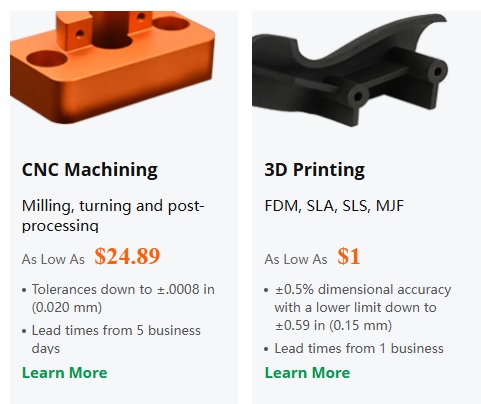

How to get CNC machining and 3D printing service

JUSTWAY CNC and 3D printing experts are the best platform for getting both services at one stop. They provide low-cost rapid prototypes and low-volume productions for different industries and projects. They provide services for production parts, functional prototypes, electrical appliances, electronics, etc.

They have many self-operated factories and outsourced factories, with a a larger range of manufacturing capabilities and one-stop prototyping and mass production. They are famous for being manufacturers of geometrically complex parts or highly cosmetic parts.

Through Justway CNC machining services, you can get 3-axis CNC milling and 5-axis indexed milling processes with more than 30+ metals and plastics and 10+ surface finishes.

They also provide industrial-grade printing, with prices starting at $1, and advanced materials. With that, their services include high-precision thread drilling designs and precision CNC machining.

Their 3D printing service comes with

- Instant Quotes & DFM Feedback

- SLA, MJF, DLP, FDM, SLM, SLS, Poly Jet, SAF Technologies

- Manufacturing Low Volume Parts

- With over 250 sets of industrial-grade 3D printing equipment, print parts in 1 day.

Different CNC Machines and uses

For CNC machines, different machines are used each performing different functions for different uses. that are

CNC Mills:

- In these machines, rotating cutting tools are used for removing materials like plastics and metals. CNC milling is used for making complicated designs and is used where high accuracy is needed.

CNC Lathes:

- Lathes work with material rotation, and cutting tools make shapes of the material. It is used for bolts, shafts, and round-shaped bodies and is mostly used for the vehicle and aviation industries.

Drills:

- CNC drills are used for making holes with an accurate diameter. It is used with CNC machines for making parts where accurate hole creation is required with special dimensions.

Grinders:

- CNC grinders operated with abrasive wheels for making smooth surface finishes on metallic parts, which is preferred for polished surfaces like vehicle components

Plasma Cutters

- Plasma cutters work with ionized gas for cutting metallic parts, and laser cutters use a slight beam for high-accuracy cutting. that are used for sheet metal processing and make complicated designs with no or low waste materials

Advantages of CNC Machining

The main features of CNC machining are as

- CNC machines provide a high tolerance of about ±0.005 mm, preferred for components where high accuracy is needed.

- CNC machining is used for different materials like wood, plastics, and metals, and has flexible working for different material features.

- With CNC machining, we get a smooth finish with low material usage after processing, which makes it useful for industries.

- For bulk productions, CNC machining is a low-cost option, since setup expenses apply to a larger number of parts, making each part low-cost.

- CNC machining also makes durable parts with consistent features and is preferred where materials face high stress.

- By using CNC, we make the same components in bulk with quality and mass production consistency.

- CNC machines have features for handling larger parts than 3D printing and are used for sizable applications.

- CNC machining during operations also maintains material quality which makes components without faults.

Disadvantages of CNC Machining

With some advantages, CNC machining also has some limitations.

- CNC is a subtractive process that also results in wastage of materials for complicated designs.

- Waste materials during CNC processing are more difficult than 3D printing.

- Since its setup cost is high, CNC machining is a costly process for low-volume or complicated designs, where 3D printing is preferred.

- CNC machining needed special setup and programming for the machine working that increased the time for setup and delayed production.

- CNC machines also needed skilled staff for setup, and its maintenance needed complicated designs.

- For complicated designs, CNC machines are not preferred; they need 3D printing for complex designs.

- CNC uses high energy and requires coolants that affect the environmen,t and need an extra treatment process.

Advantages of 3D Printing

The main advantages of 3D printing are as follows.

- 3D printing is used for making complicated designs that are not made with CNC machining, like lattice geometries and inner structures.

- It is an additive manufacturing process; 3D printing applies the material that is needed for each layer, which reduces material wastage more than CNC.

- Its feature to convert design into an object fast makes this process best for high-speed prototyping and preferred where high-speed design-to-project conversion is needed.

- It does not use costly tools or structures and has low costs for low-volume manufacturing, whereas CNC machining uses high costs.

- We can make changes in designs easily with low effort and without using extra tools; that is, simple methods for making customized components.

- It needed a low skill set for the operator and was used for a larger base of users than CNC.

- 3D printing, preferred for bulk customization, helps to make products with high efficiency, and in the electronics industry

- As compared to CNC machining, 3D printing makes internal cavities and some complex designs.

Disadvantages of 3D Printing

Either 3D printing has advantages or it also has some limitations.

- Either the 3D printing process is effective but has lower accuracy than CNC machining. It needed post-processing for a quality surface and high-dimensional accuracy.

- For 3D printing, high-performance metals are not available but are high-cost, which increases the overall process cost.

- It also needed post-processing steps, such as sanding and polishing, to get the required standards and features.

- For single-unit creation, the cost per unit can be low compared to CNC for larger volumes.

- 3D-printed objects also have weaker strength in some directions, affecting the strength more than CNC-machined parts.

- 3D printer is limited with volume, which controls object size without using smaller pieces.

- Either it is preferred for prototypes and custom parts but does not work for bulk production, since the printer makes one unit at a time.

3D Printing vs. CNC Machining

Lead Cost

- CNC machining manages programming and setup charges and is more expensive than 3D printing, typically 5 times higher than 3D printing.

- For projects where many prototypes with small changes are needed, certain CNC-made parts are more costly than 3D-printed parts that have the same cost for each part.

Process Speed

- for printing 3D components, printing requires less time for setup before the printing process. Printing is a slow process for some factors; some prints are complicated and shortened and are now ready for further processing.

- While CNC machining needs a properly skilled operator for programming, cutter selection and cutter path.

- it also needed custom modules for processing parts. That takes more time before the first cutting. So cutting is high speed, and complicated designs are made shortly with actual machining. Based on design, complication, preparation time, and matching, it varies.

Volume

- If a larger setup is used for different parts, CNC machining makes lower-cost parts compared to 3D printing.

- 3D printing uses the same material and machine cost regardless of which volume is made.

Materials

- CNC has good material selection features, with material selection based on the material. CNC-made components have basic features of billet materials and are highly applied through processing features.

- 3D printed parts are limited to certain processes. The manufacturing process of 3D printing has some limitations for features.

- 3D printing is not used for certain operations. The production process of special 3D printing methods applies some restrictions for features on demand.

| Feature | 3D Printing | CNC Machining |

| Unlimited material access | No | Yes |

| Design | limited to process constraints | Limited for axis-defined minimum radii, undercut and internal access, tool path and type, |

| Precision | 0.016 resolution to 1 mm+. around 0.2 mm. | 0.005 mm precision, mostly for using a slow feed, new cutters, |

| Operator skill | low | high |

| Speed manufacturing | Low setup time required, but build time can be longer | It can take a long time for and program, but cutting can be fast |

| Surface finish | Grained, rough, and stepped, and can be blurred quite often | very high-quality surfaces by taking long time for cutting |

| Strength | 10–20% of native material | 100% of the native material |

| Cost | $50-70 per part for a small, simple design | $300–$500 per part, simple design without changes in design |