3D printing is a process that is used for making different objects according to digital model files, with the use of bondable materials like plastic or powdered metals, and after printing in layer form. The printed materials come from 3D models and related electronic data. With that printed 3D object comes different shapes and layout features. In this post, we will cover details for different materials used for 3D printing services and related factors.

Different 3D printing technologies

- 3D printing is operated with the use of CAD for making 3D objects with applications of layered processes.

- First, a graphic model of printed objects is made with the use of computer-aided design software packages.

- Import files into the 3D printer, and the printer finishes the complete work.

- Based on working features, the 3D printing process has 3 different types.

Color 3D Printing Processes

FDM (Fused Deposition Modeling)

- FDM is a common and low-cost technology used for 3D printing. FDM 3D printers make parts through melting and extruding thermoplastic filament that deposits with the printer nozzle in layers to form thepart.

- FDM is normally direct color printing through single-extruder printers or also multicolor 3D printing through dual-extruder printers.

- • The first full-color FDM printer is the da Vinci Color 3D printer, having colorless filament dyed through use of inkjet cartridges that make colored parts like a color 2D printer.

- Multi-color printing uses the FDM+AMS process. FDM materials have lower transparency. Justway offers two types of multi-color printing: full-color resin and full-color PLA. Full-color resin has no color restrictions, while full-color PLA supports up to four colors. Currently they don’t have a button on their website to select multiple colors, but users can specify this when placing an order.

- Please note: the order file must be in OBJ format and include MTL texture files. When placing an order, please upload all required files in a folder. Justway sales staff will then review the order and provide it to their factory, which will then begin production and shipment.

SLS (Selective Laser Sintering)

- This method utilized powder to spread materials on the top surface of the molded part, and heat was applied at a temperature below the sintering point of the powder.

- The control system regulates the laser beam on powder layers based on the cross-sectional design of the layer.

- When the scan is complete, the temperature of the powder goes to the melting point, sintering and bonding with the molded side.

- When one layer is finished, the working bench height reduces to one layer thickness, and spread roller layers for uniform and dense powder are there.

SLA (Stereo Lithography Apparatus)

- liquid tank having liquid photosensitive resin that cures in a UV laser beam released with the laser.

- At the start of forming, lift the worktable to a lower liquid level, one section high in thickness.

- • A laser beam focused with a lens scans a profile over the liquid surface based on machine guidelines.

- Resin in the scanning area solidifies for completing processing of layers of cross section and gets layers of plastic sheet.

- After that, the workbench reduces the height of one layer’s thickness; after that, the other layer is applied.

- These layers are applied for making 3D objects.

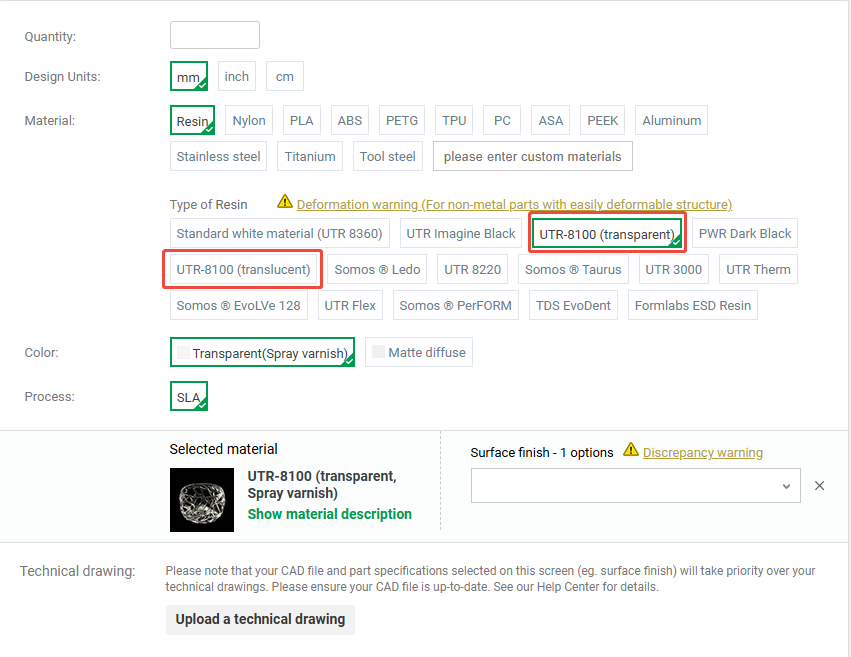

- At Justway SLA Printing Services, you can get transparent printing material, UTR8100 resin, using the SLA process. Their SLA 3D printing capability are as

| Size | Metric units |

| Max part size | 2100*800*700mm |

| Min. feature size | 0.5mm |

JUSTWAY Launches Transparent and Multi-Color 3D Printing Services to Empower Creative and Engineering Applications

As 3D printing technology continues to advance, users are demanding higher-quality visual and functional models. To meet the needs of professional designers, prototyping engineers, and creative makers, JUSTWAY has launched transparent and multi-color 3D printing services, offering more versatile material and visual options.

1. High-Transparency Printing: UTR8100 Resin + SLA Technology

JUSTWAY’s transparent printing utilizes UTR8100 high-transparency resin combined with SLA (Stereolithography) technology, delivering excellent light transmission, smooth surfaces, and precise details.

This solution is ideal for:

Optical components and light-transmitting prototypes

Lampshades and transparent display covers

High-precision visual models and functional verification parts

2. Multi-Color Printing: Full-Color Resin & Full-Color PLA

JUSTWAY’s multi-color printing leverages FDM + AMS technology and offers two flexible solutions:

Full-Color Resin Printing: Unlimited color options with fine details, ideal for display models and creative designs.

Full-Color PLA Printing: Supports up to four colors per print, suitable for multi-color prototypes or functional models. (Note: FDM materials have lower transparency.)

3. Order Guidelines

While our website does not currently provide a direct multi-color selection button, customers can specify their requirements via order notes. Please follow these steps when placing an order:

File Format: Models must be in OBJ format with the MTL texture file included.

File Upload: Package all required files into a single folder before uploading.

Order Notes: Specify the required colors or multi-color printing request in the order note.

Order Processing: Our sales team will review the order and confirm it with the factory before production and shipping.

With the launch of transparent and multi-color 3D printing services, JUSTWAY empowers users to achieve highly accurate visual models and unleash unlimited creative possibilities. Learn more: https://www.justway.com/

Materials for 3D Printing

- From this suppliers, you can ge standard 3d printing materials are as on single platform.

3D Printing Plastics

| Resin | Nylon | Other Plastic |

| Standard white material (UTR 8360) | HP-PA-12 | PEEK |

| Somos ® Ledo | PA12 | ABS |

| UTR 8100 (transparent) | Glass fiber nylon(PA12+35% GF) | Stratasys ABS-ESD7 |

| UTR Imagine Black | PLA | |

| PWR Dark Black | PC (Polycarbonate) | |

| UTR 8220 | TPU | |

| Formlabs ESD Resin | PETG | |

| Somos ® Taurus | ASA | |

| Somos ® PerFORM | ||

| UTR Flex | ||

| UTR Therm | ||

| UTR 3000 | ||

| UTR-8100 (translucent) | ||

| Somos ® EvoLVe 128 | ||

| TDS EvoDent |

| Aluminum | Stainless steel | Titanium | Tool steel |

| Aluminum (AlSi10Mg) | Stainless steel 316L | Titanium TC4 | Tool steel |

3D printing service features

Flexible Design

- 3D printing helps to make and print complicated designs as compared to conventional manufacturing processes. Some conventional methods come with design limitations that do not apply to 3D printing.

Rapid Prototyping

- 3D printing also makes parts in less time, which increases prototyping speed. that increases the speed of each step. As compared to machining prototyping, 3D printing is low-cost and high-speed for making parts, which helps to make changes in design with an effective rate.

Printed on Demand

- printed on demand other features since it does not need much space, as compared to conventional processes. It saves time and cost since there is no need for printing in larger volumes according to requirements.

- The 3D design files are stored in a virtual library when made with the use of a 3D model in the form of a CAD file, so they can be printed when needed. We can make changes in designs at low costs through changes in the in files

Low-weight Parts

- Normally, 3D printing materials use plastic, since some metals are used for 3D printing. Plastics provide features since they are lower in weight than metals. It is good to use in the vehicle and aviation industries and provides fuel efficiency.

- parts also made from materials for providing features like water resistance, heat resistance

Fast Production

- According to object design and complications, 3D printing has the feature to print objects in a short time; that is, it is a higher-speed process than molding parts. It makes parts in a short time with the design process through making STL or CAD files ready to be printed.

low waste

- The manufacturing of parts needed materials for parts and did not provide higher waste than other methods that cut with larger parts of non-recyclable materials. It not only saves materials but also reduces extra cost.

low cost

- Since it uses a single manufacturing process, 3D printing takes less time and has other cost factors. 3D printers also do not need operators to control the process full-time.

- • The manufacturing process also reduces material costs since it uses required materials with low waste.

Access

- 3D printers are easy to access with local service providers that offer outsourcing services for manufacturing. It takes less time and does not need high transportation costs compared to conventional manufacturing processes.

FAQs

Can you 3D print with transparent material?

- Yes, transparent plastic parts can be made with the use of 3D printing. The optimal method for 3D printing clear or transparent plastic objects is stereolithography, or SLA, 3D printing.

- Filament-based 3D printing does not provide the required transparency since a small gap is created between layers of material.

Can 3D printers print multicolor?

- FDM 3D printers print in a single color with the use of colored filament, in 2 colors with the use of a dual extruder, or in different colors and gradients through mixing different colors, based on the filaments passed through the printer.

Is multi-material 3D printing worth it?

- Multi-material 3D printing is good when needed to mix 2 complementary material features in one component, like partially rigid and flexible.

What materials cannot be 3D printed?

- materials that burn rather than melt with high temperature and are not processed through sintering or melting, also used when extruded in a nozzle for 3D printing. wood, cloth, and paper not printed with use of the of3d printing process